Copper alginate/copper ferrocyanide blend fiber and preparation method thereof

A technology of copper ferrocyanide and copper alginate, which is applied in the fields of fiber chemical characteristics, spinning solution preparation, alginate artificial filament, etc. Small copper particle size and other problems, to achieve high cesium removal efficiency, small particle size, and improve the effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

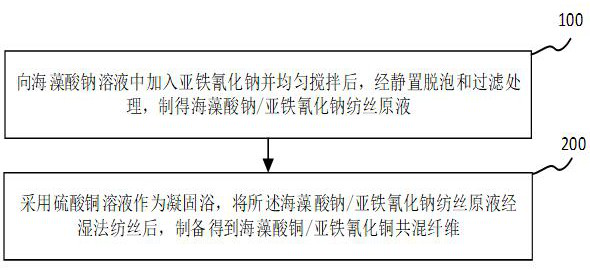

[0026] in, figure 2 It is a method flow chart of a method for preparing a copper alginate / copper ferrocyanide blend fiber shown according to an exemplary embodiment of the present invention. Such as figure 2 As shown, the method includes:

[0027] In step 100, sodium ferrocyanide is added to the sodium alginate solution and evenly stirred, and then the sodium alginate / sodium ferrocyanide spinning stock solution is obtained by standing for defoaming and filtering.

[0028] The mass fraction of sodium alginate in the sodium alginate solution is 4.5-5.5%, and the mass fraction of sodium ferrocyanide in the sodium alginate / sodium ferrocyanide spinning stock solution is 3-8%.

[0029] In step 200, copper sulfate solution is used as a coagulation bath, and the sodium alginate / sodium ferrocyanide spinning stock solution is subjected to wet spinning to prepare copper alginate / copper ferrocyanide blended fibers.

[0030] The mass fraction of copper sulfate in the copper sulfate so...

Embodiment 1

[0041] (1) After adding sodium ferrocyanide to the sodium alginate solution and stirring evenly, the sodium alginate / sodium ferrocyanide spinning stock solution was obtained by standing for defoaming and filtering.

[0042] The mass fraction of sodium alginate in the sodium alginate solution is 4.5%, and the mass fraction of sodium ferrocyanide in the sodium alginate / sodium ferrocyanide spinning stock solution is 3%.

[0043] (2) Copper sulfate solution is used as a coagulation bath, and the sodium alginate / sodium ferrocyanide spinning stock solution is wet-spun to prepare copper alginate / copper ferrocyanide blend fibers.

[0044] The massfraction of copper sulfate in described copper sulfate solution is 5%.

Embodiment 2

[0046] (1) After adding sodium ferrocyanide to the sodium alginate solution and stirring evenly, the sodium alginate / sodium ferrocyanide spinning stock solution was obtained by standing for defoaming and filtering.

[0047] The mass fraction of sodium alginate in the sodium alginate solution is 5%, and the mass fraction of sodium ferrocyanide in the sodium alginate / sodium ferrocyanide spinning stock solution is 5%.

[0048] (2) Copper sulfate solution is used as a coagulation bath, and the sodium alginate / sodium ferrocyanide spinning stock solution is wet-spun to prepare copper alginate / copper ferrocyanide blend fibers.

[0049] The massfraction of copper sulfate in described copper sulfate solution is 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com