Temperature and humidity cascade control method based on AHU return air unit

A cascade control, temperature and humidity technology, applied in the field of temperature and humidity cascade control based on AHU return fan units, can solve the problems of low control accuracy, waste of cold and heat sources, repeated large or small opening, etc., to improve system control. Quality, system control, high efficiency and energy saving, the effect of reducing the same opening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

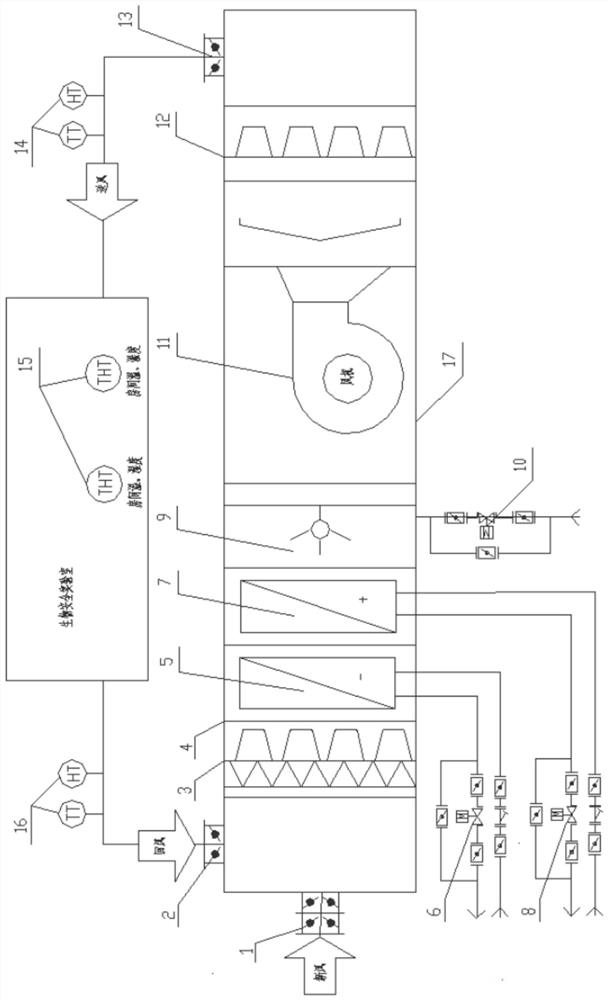

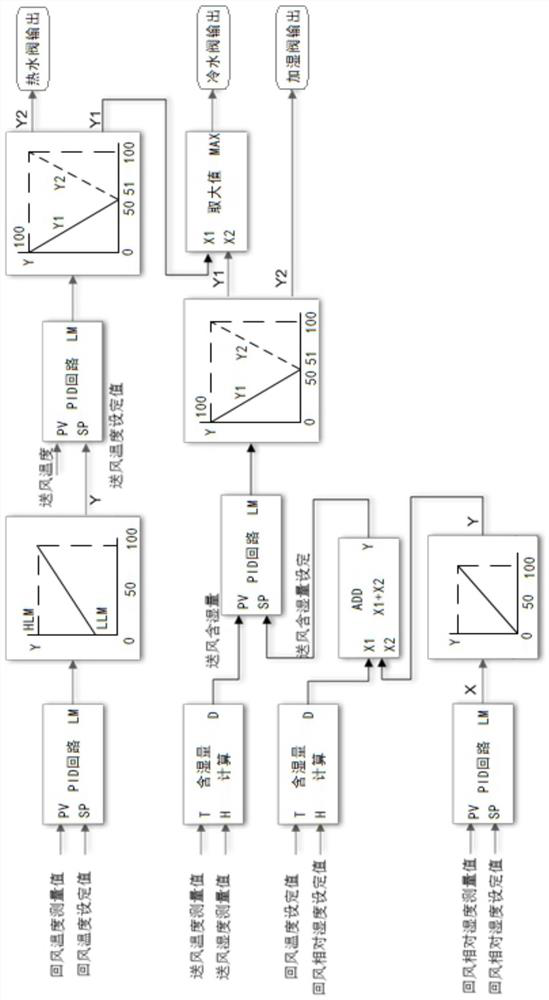

[0045] The application of the temperature and humidity cascade control technology based on the AHU return air unit in the biosafety laboratory is further described in detail:

[0046] (1) Multiple temperature and humidity sensors are installed at different key positions in the controlled room of the laboratory, and the indoor multi-point temperature and humidity average calculation method is adopted to automatically eliminate fault values. The average value is used as the actual temperature and humidity reference value of the room, and the temperature and humidity alarm is set. When the limit is exceeded, the system will send out an alarm.

[0047] (2) Determine that the required temperature target value in the laboratory is 22°C and the humidity target value is 55%, and take the actual measured values of the return air outlet and air supply outlet temperature and humidity sensors (return air temperature and humidity sensor 16 and supply air temperature and humidity sensor 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com