Freeze-drying method of recombinant human pro-urokinase for injection

A technology for prourokinase and injection, which is applied in the field of lyophilization of recombinant human urokinase for injection, which can solve the problems of inconvenience, easy collapse of lyophilized powder, and low eutectic point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

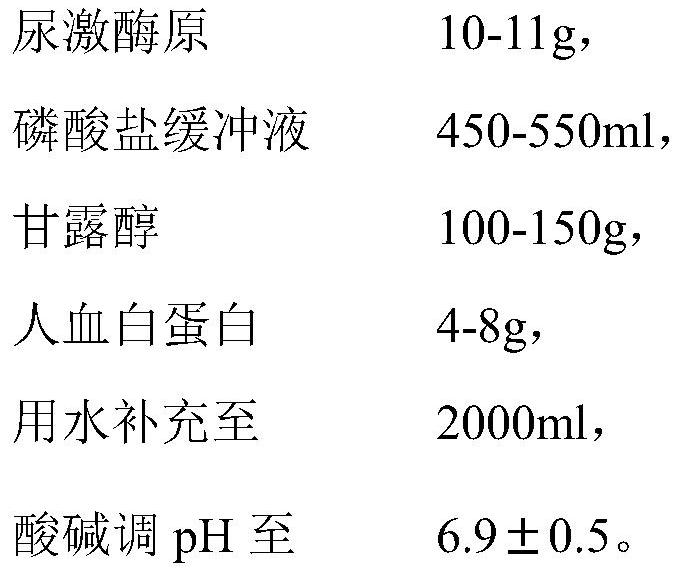

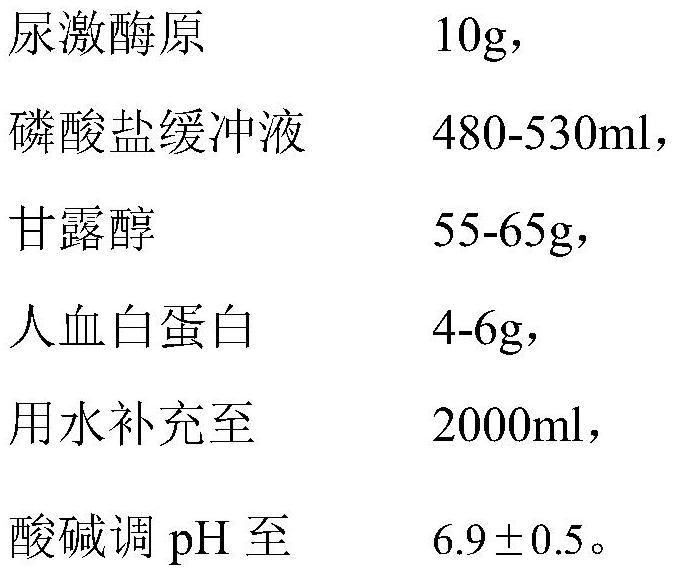

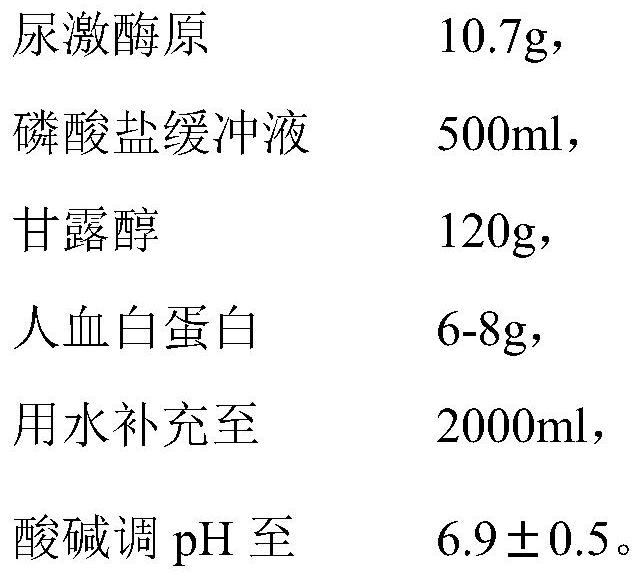

[0120] Embodiment 1: Raw material of prourokinase freeze-dried powder for injection

[0121] It is made of the following components by weight (1000 tubes as an example): 10.7g of prourokinase, 500ml of phosphate buffer, 120g of mannitol, 6g of human serum albumin, supplemented with water to 2000ml, and pH adjusted to 6.9±0.5 .

Embodiment 2

[0122] Embodiment 2: freeze-drying process

[0123] 1. Product pre-freezing and annealing: After filling, put the product into a freeze-drying box for product pre-freezing. During the pre-freezing process, the set temperature of the plate layer is -40°C. See the table below for each parameter setting. After the product temperature is stable Anneal at -25°C;

[0124] Table 10: Setting of prefreezing parameters

[0125] Set temperature(°C) Setting time (min) Duration (min) Phase 1 -2 1 30 Phase 2 -40 60 60 Phase 3 -25 10 120 Phase 4 -40 30 90

[0126] 2. Primary drying: During the primary drying process, the freeze-drying box needs to be aerated, and the air aeration is controlled between 20±5Pa, and the temperature of the plate layer rises to -20℃~-10℃. The parameters are set in the table below, and Hold steady until the product waterline disappears.

[0127] Table 11: Parameter settings for primary drying

[0128] ...

experiment example 1

[0132] Experimental Example 1: Analyzing the Drying and Screening Process

[0133] On the basis of pre-freezing parameters, annealing parameters and primary drying parameters, the secondary drying is carried out, that is, the optimization of analytical drying parameters. During the research process, three groups of experiments TA, TB and TC were designed. The analysis temperature of group TA was set at 30°C, that of group TB was set at 35°C, and that of group TC was set at 40°C. The specific parameters of each stage are controlled as shown in Table 13:

[0134] Table 13: Analytical drying optimization experimental parameters

[0135]

[0136] The parameters in Table 13 show that after pre-freezing at -40°C, annealing at -25°C is carried out, drying is carried out at -10°C once, and then the temperature rises to 30°C, 35°C, and 40°C for analytical drying until the pressure rise does not exceed 0.01 After mbar / min, the plug is fully pressed out of the box. According to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com