Unfired environment-friendly brick prepared from stripped soil in mine and preparation method of unfired environment-friendly brick

An environmentally friendly brick and mine technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as soil problems, high transportation costs, harm to the surrounding environment, etc., to achieve simple process flow, low cost, Suitable for promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

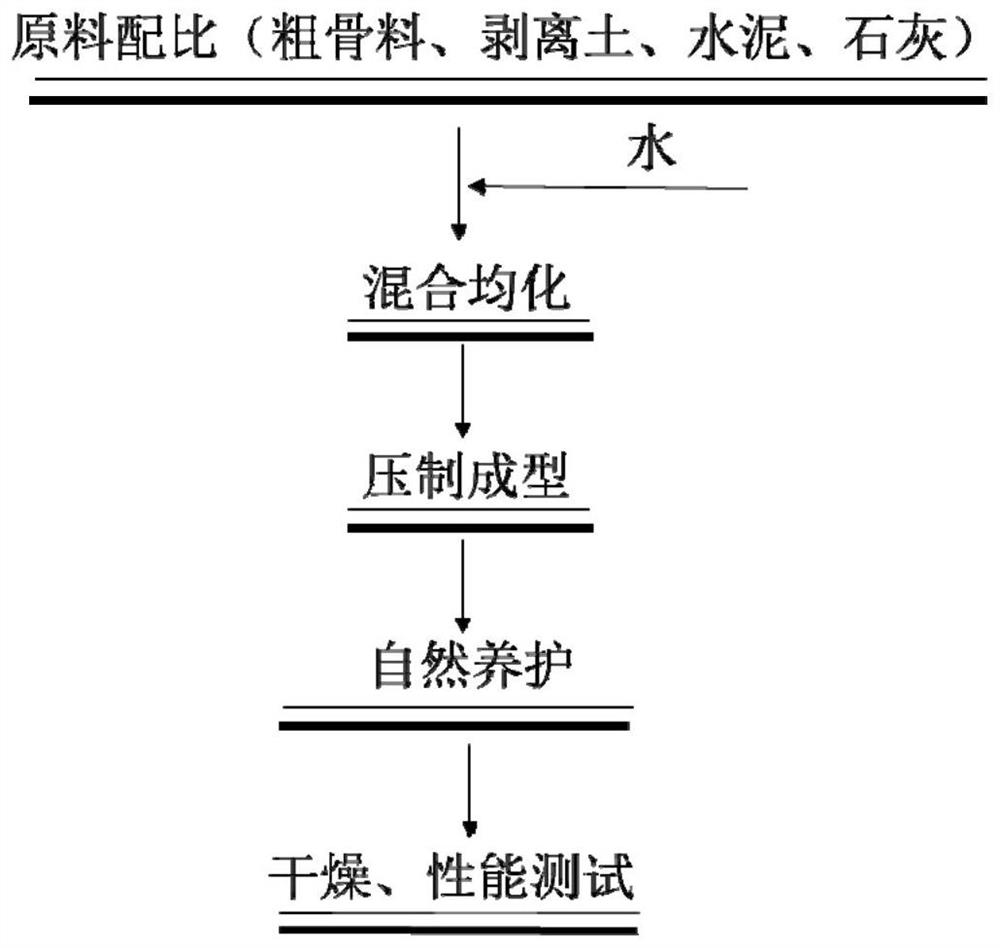

[0028] This embodiment provides a method for preparing non-burning environmentally friendly bricks using mine stripping soil, including the following steps:

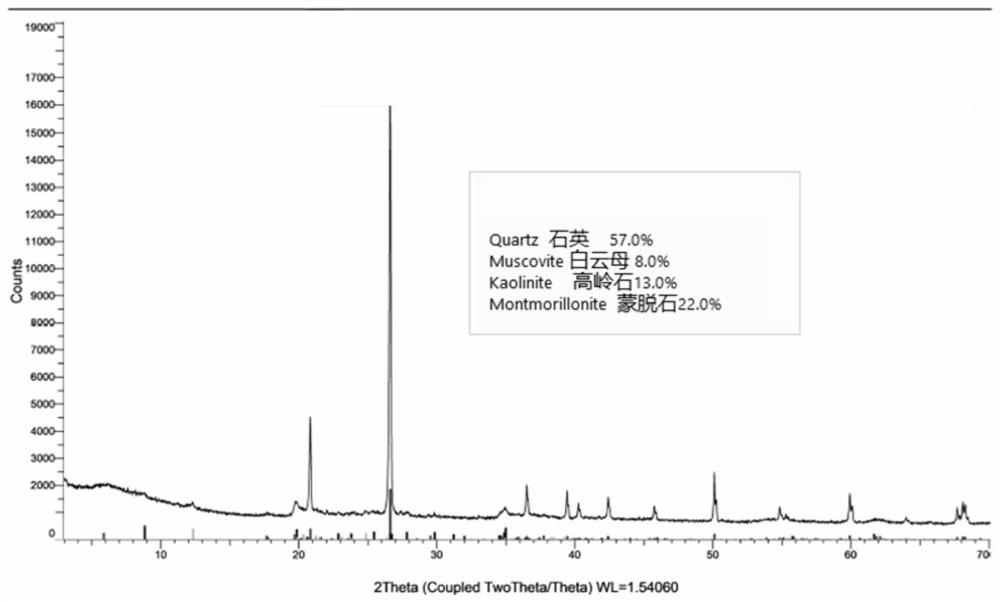

[0029] Step S1, raw material preparation: Crushing the collected limestone and sieving to obtain coarse sand aggregate; mixing the prepared coarse sand aggregate with limestone mine stripping soil at a weight ratio of 1:4 to form sandy soil Mixture;

[0030] Step S2, ingredient batching: mix and age the sand-soil mixture, 42.5-grade Portland cement, and lime in a weight ratio of 20:3:2;

[0031] Step S3, mixing and stirring: put the raw materials into the cement mortar mixer, add 10wt% water, and stir for 3-5 minutes;

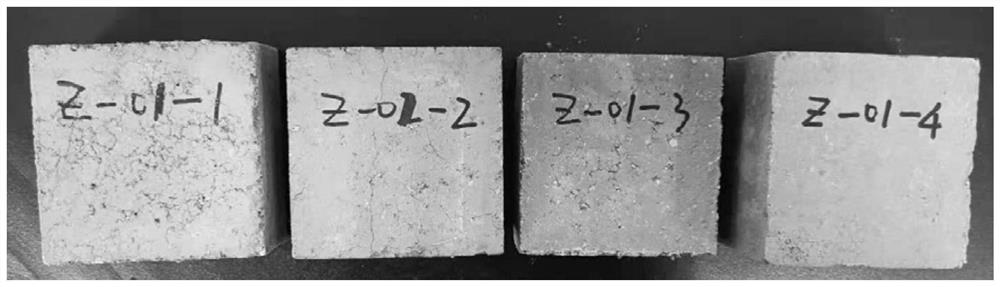

[0032] Step S4, compression molding: put the mixture in the mold, vibrate easily to make the surface of the mixture in the mold smooth, then put the mold into a constant pressure testing machine, set the compressive strength to 20MPa, and maintain a constant pressure 10s, after the end, take out the mol...

Embodiment 2

[0036] This embodiment provides a method for preparing non-burning environmentally friendly bricks using mine stripping soil, including the following steps:

[0037] Step S1, raw material preparation: crush the collected limestone and sieve to obtain coarse sand aggregate; mix the prepared coarse sand aggregate with limestone mine stripping soil at a weight ratio of 2:3 to form sandy soil Mixture;

[0038] Step S2, ingredient batching: mix and age the sand-soil mixture, 42.5-grade Portland cement, and lime in a weight ratio of 20:3:2;

[0039] Step S3, mixing and stirring: put the raw materials into the cement mortar mixer, add 10wt% water, and stir for 3-5 minutes;

[0040] Step S4, compression molding: put the mixture in the mold, vibrate easily to make the surface of the mixture in the mold smooth, then put the mold into a constant pressure testing machine, set the compressive strength to 20MPa, and maintain a constant pressure 10s, after the end, take out the mold and re...

Embodiment 3

[0044] This embodiment provides a method for preparing non-burning environmentally friendly bricks using mine stripping soil, including the following steps:

[0045] Step S1, raw material preparation: crush the collected limestone and sieve to obtain coarse sand aggregate; mix the prepared coarse sand aggregate with limestone mine stripped soil at a weight ratio of 3:2 to form sandy soil Mixture;

[0046] Step S2, ingredient batching: mix and age the sand-soil mixture, 42.5-grade Portland cement, and lime in a weight ratio of 20:3:2;

[0047] Step S3, mixing and stirring: put the raw materials into the cement mortar mixer, add 10wt% water, and stir for 3-5 minutes;

[0048] Step S4, compression molding: put the mixture in the mold, vibrate easily to make the surface of the mixture in the mold smooth, then put the mold into a constant pressure testing machine, set the compressive strength to 20MPa, and maintain a constant pressure 10s, after the end, take out the mold and rel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap