Bio-based phosphorus-magnesium flame retardant, preparation method and flame-retardant cable composite material

A technology for flame retardant cables and flame retardants, applied in the field of cable insulation, can solve problems such as the generation of toxic fumes, and achieve the effects of protecting the earth's environment, excellent mechanical properties, and excellent low fumes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

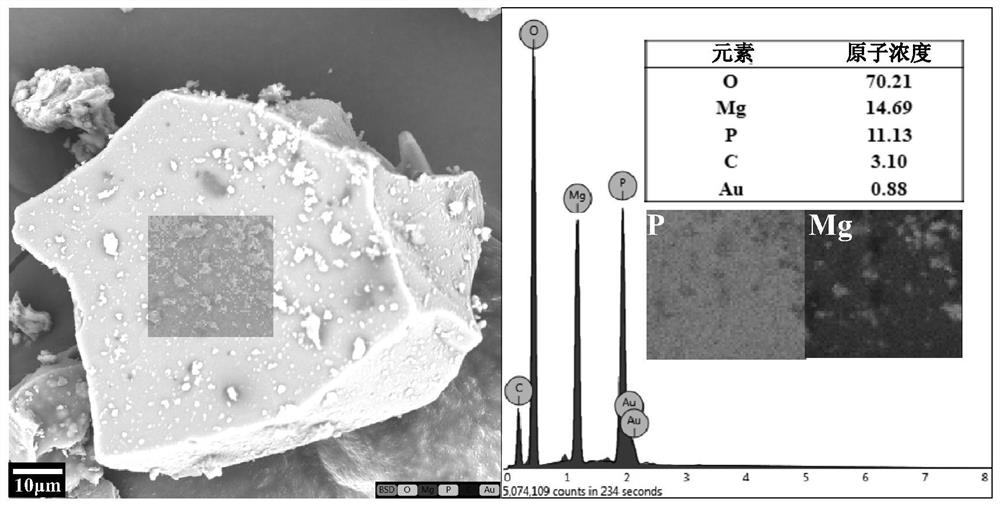

[0043] This embodiment relates to a preparation method of a bio-based magnesium phosphorus flame retardant, such as figure 1 As shown, it specifically includes the following steps:

[0044]5.00 g of MH was added to 100 ml of water and stirred for 5 min to form a homogeneous suspension. Then, slowly drop 13.3ml of PA solution (70wt%) into the suspension, continue stirring for 5min, then wash the resulting bulk product MHPA1, then dry at 60°C for 48h, and finally sieve the product (200 mesh) to obtain a homogeneous Granular powder MHPA1.

[0045] Add 8.00g of MHPA1 into 100ml of water and stir for 5min. Then 6ml of PA (30wt%) was diluted in water (100ml). Thereafter, the diluted PA aqueous solution was slowly dropped into the homogeneous suspension of MHPA1 by continuous stirring. After continuous stirring for 10 minutes, MHPA2 was obtained. After washing in warm water at 50°C, it was dried in an oven at 60°C for 48 hours. Finally, the product was sieved (200) to obtain unif...

Embodiment 2

[0048] This embodiment relates to a preparation method of a bio-based phosphorus magnesium flame retardant, specifically comprising the following steps:

[0049] 10.00 g of MH was added to 150 ml of water and stirred for 10 min to form a homogeneous suspension. Then, slowly drop 14ml of PA solution (80wt%) into the suspension, continue to stir for 10min, then wash the resulting bulk product MHPA1, then dry at 80°C for 50h, and finally sieve the product (250 mesh) to obtain a uniform Granular powder MHPA1.

[0050] Add 10.00g of MHPA1 into 150ml of water and stir for 10min. Then 10ml PA was diluted in water (150ml). Thereafter, the diluted PA aqueous solution was slowly dropped into the homogeneous suspension of MHPA1 by continuous stirring. After continuous stirring for 15 minutes, MHPA2 was obtained. After washing in warm water at 60°C, it was dried in an oven at 80°C for 50 hours, and finally the product was sieved (250) to obtain uniform particle powder MHPA2.

[0051] ...

Embodiment 3

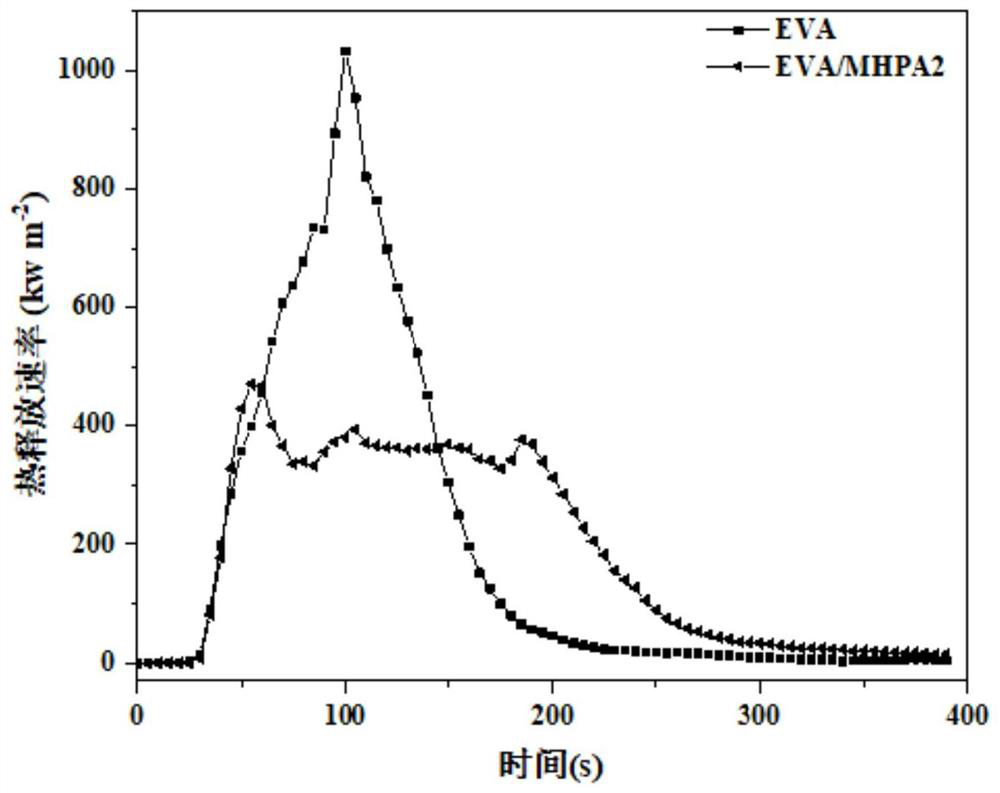

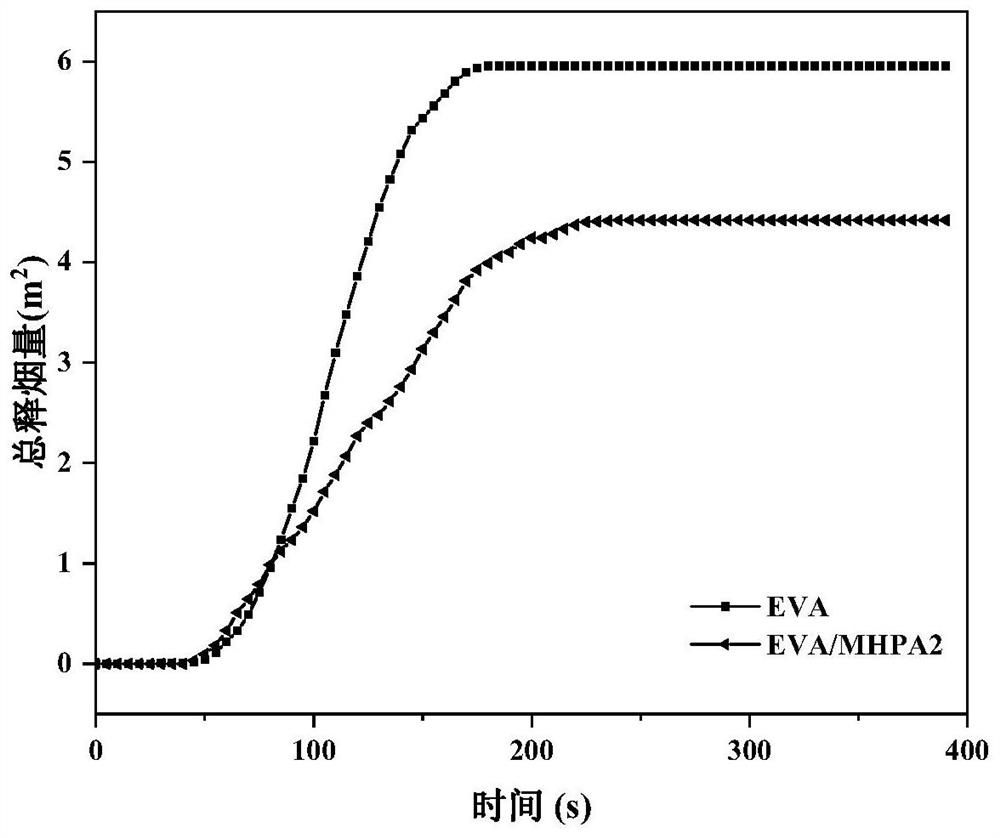

[0053] This embodiment relates to a preparation method of an EVA-based flame-retardant cable composite material, which specifically includes the following steps:

[0054] The MHPA2 and MH in Example 1 were blended into EVA at a ratio of 4:1 by means of melt blending to prepare an EVA-based flame-retardant cable composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com