Butterfly welding equipment

An equipment and butterfly technology, applied in the field of butterfly welding equipment, can solve the problem of low quality of battery cells, and achieve the effect of avoiding burrs and explosions, avoiding aging, and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

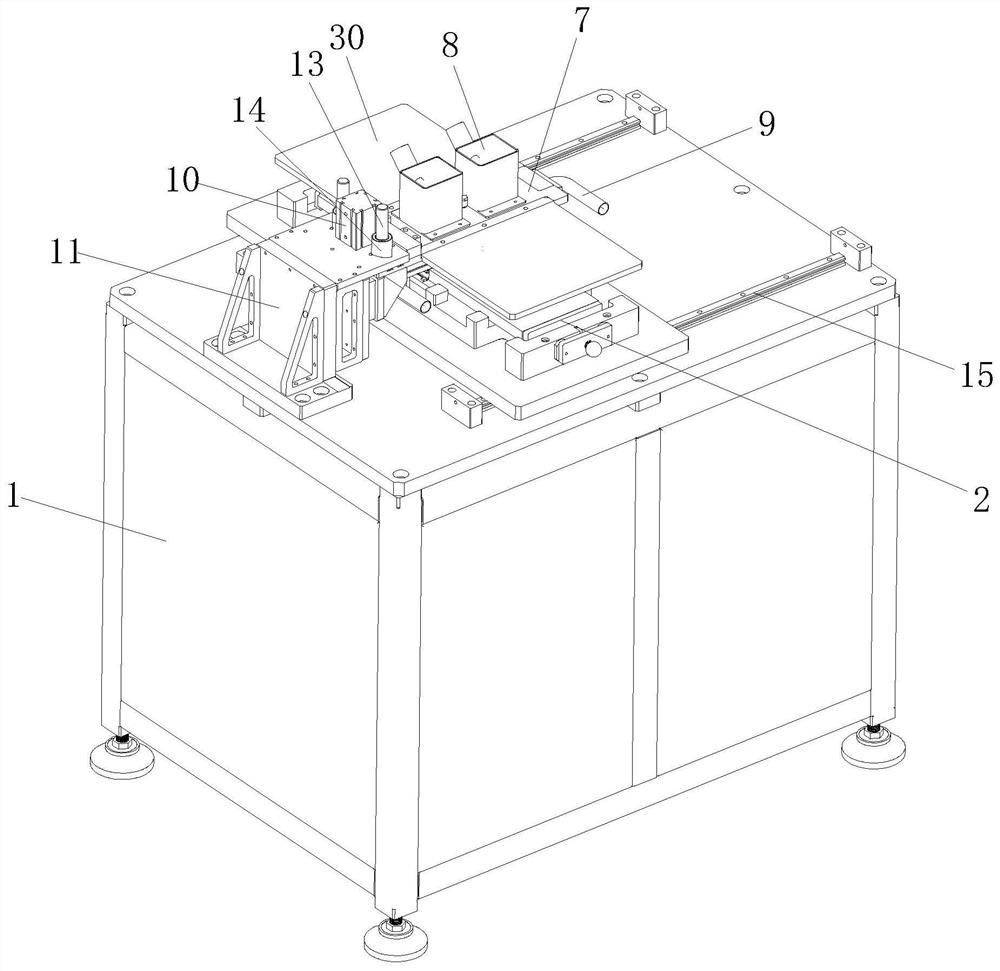

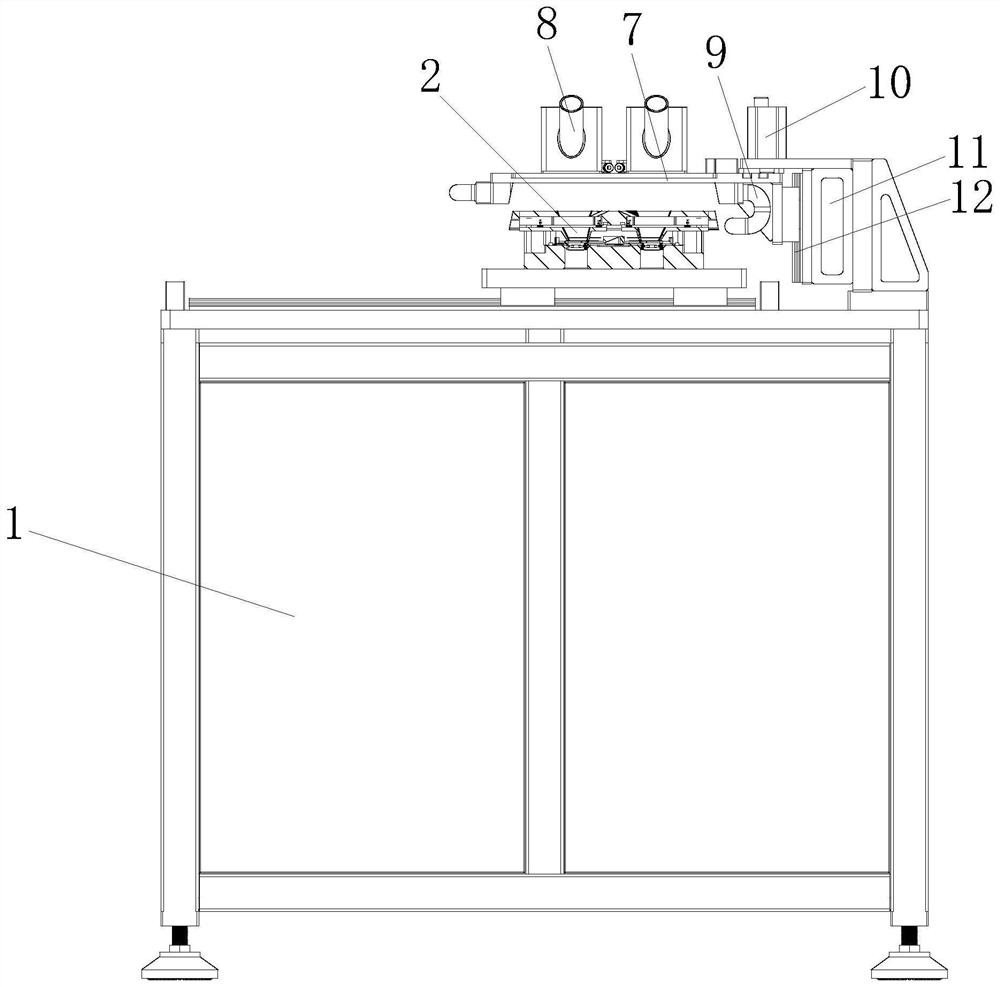

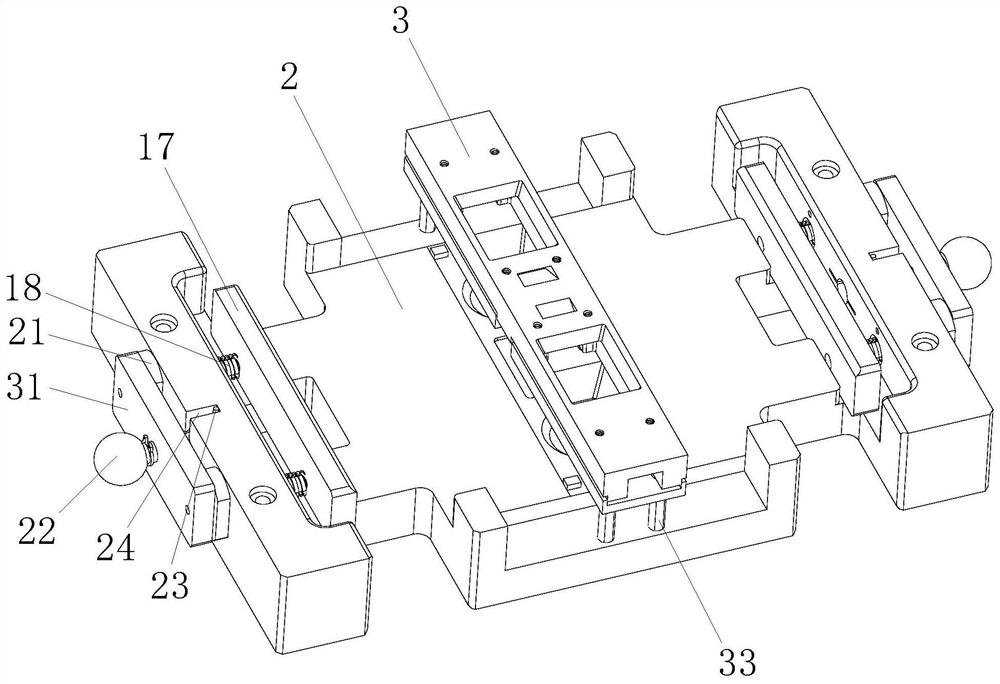

[0035] In order to further understand the content of the present invention, in conjunction with the attached Figure 1-9 And embodiment describe the present invention in detail.

[0036] combined with Figure 1-9 , a butterfly welding device in this embodiment, comprising a welding platform 1 and a positioning platform 2, the positioning platform 2 can move horizontally on the welding platform 1, a second slide rail 15 is installed on the welding platform 1, The positioning platform 2 is installed on the second slide rail 15, the positioning platform 2 is provided with a welding pressure head 3, and the welding pressure head 3 is provided with a laser guide channel 4; the first guide channel 5, and The laser guide channel 4 communicates with the inert gas; the second guide channel 6 communicates with the laser guide channel 4 and is used for discharging the inert gas and welding slag; Action platen 7, the positioning platform 2 can be slid to directly below the platen 7 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com