Environment-friendly degradable food-grade antibacterial plastic packaging film and preparation process thereof

A technology of antibacterial plastics and preparation technology, which is applied in the sustainable packaging industry, sustainable manufacturing/processing, packaging, etc., can solve the problems of food perishability and poor antibacterial effect, and achieve the effect of avoiding poor antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

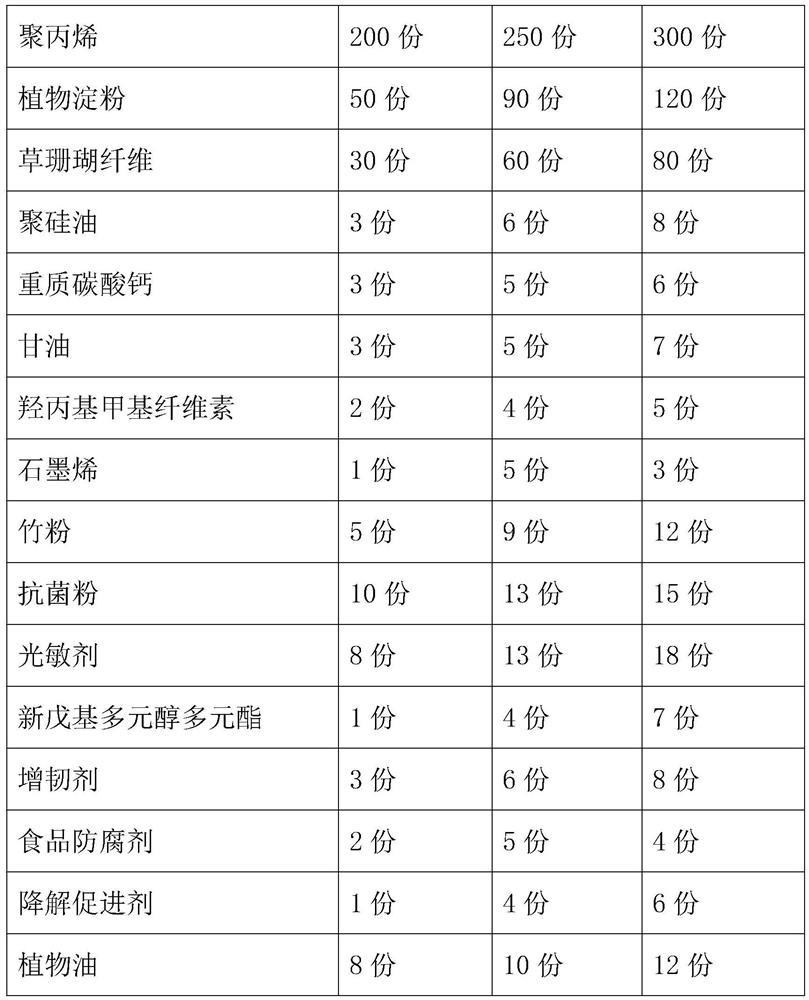

Embodiment 1

[0024] An environmentally friendly and degradable food-grade antibacterial plastic packaging film. The formula of the environmentally friendly and degradable food-grade antibacterial plastic packaging film includes: 200 parts of polypropylene, 50 parts of plant starch, 30 parts of grass coral fiber, 3 parts of polysilicone oil, heavy carbonic acid 3 parts of calcium, 3 parts of glycerin, 2 parts of hydroxypropyl methylcellulose, 1 part of graphene, 5 parts of bamboo powder, 10 parts of antibacterial powder, 8 parts of photosensitizer, 1 part of neopentyl polyol polyester, toughening 3 parts of antiseptic, 2 parts of food preservative, 1 part of degradation accelerator, 8 parts of vegetable oil;

[0025] Wherein, the photosensitizer includes one or more combinations of aromatic ketones, aromatic amines, transition metal carboxylates, transition metal inorganic complexes, ferrocene derivatives and metal dithioformates.

[0026] Wherein, the antibacterial powder includes one or a...

Embodiment 2

[0036] Different from Example 1, in terms of parts by mass, the formula of the environmentally friendly and degradable food-grade antibacterial plastic packaging film includes: 250 parts of polypropylene, 90 parts of vegetable starch, 60 parts of grass coral fiber, 6 parts of polysilicone oil, weight 5 parts of calcium carbonate, 5 parts of glycerin, 4 parts of hydroxypropyl methylcellulose, 5 parts of graphene, 9 parts of bamboo powder, 13 parts of antibacterial powder, 13 parts of photosensitizer, 4 parts of neopentyl polyol polyester, 6 parts of toughening agent, 5 parts of food preservative, 4 parts of degradation accelerator, 10 parts of vegetable oil.

Embodiment 3

[0038] Different from Example 1, in terms of parts by mass, the formula of the environmentally friendly and degradable food-grade antibacterial plastic packaging film includes: 300 parts of polypropylene, 120 parts of vegetable starch, 80 parts of grass coral fiber, 8 parts of polysilicone oil, weight 6 parts of calcium carbonate, 7 parts of glycerin, 5 parts of hydroxypropyl methylcellulose, 3 parts of graphene, 12 parts of bamboo powder, 15 parts of antibacterial powder, 18 parts of photosensitizer, 7 parts of neopentyl polyol polyester, 8 parts of toughening agent, 4 parts of food preservative, 6 parts of degradation accelerator, 12 parts of vegetable oil.

[0039] The specific formula data of three groups of embodiments of the present invention are as follows:

[0040]

[0041]

[0042] The environmentally friendly and degradable food-grade antibacterial plastic packaging film in the present invention uses polypropylene as the main material, and uses plant starch and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com