Evaporation material control system and method

A material control system and material technology, applied in vacuum evaporation plating, metal material coating process, ion implantation plating, etc., can solve the problems of reducing equipment service life, reducing production efficiency, shortening running time, etc., and achieving increased operation time, increase productivity, and precisely control the effect of evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

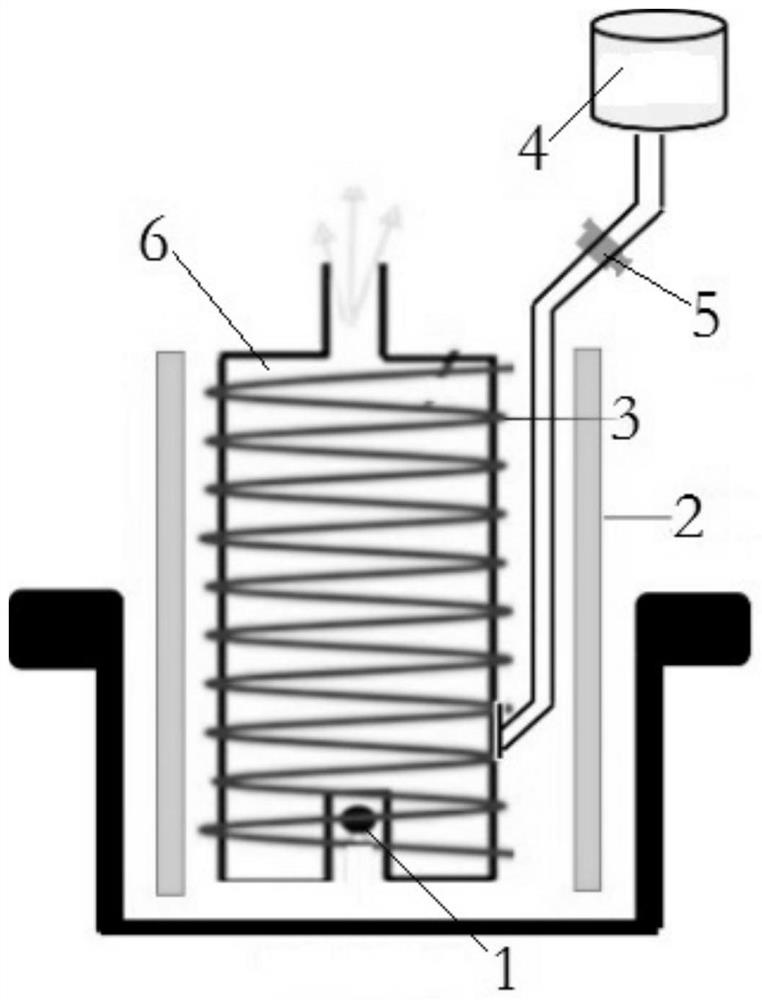

[0028] The present invention provides an evaporation material control system. In this embodiment, the preparation of a light absorbing layer of a CIGS solar cell is taken as an example. The Cu, In, and Ga metal sources of the light-absorbing layer of CIGS solar cells are distributed on both sides according to certain rules, and there are 8-10 Se sources in the middle. Quartz Crystal Microbalances (Quartz Crystal Microbalance, QCM for short) are installed on the four corners of the evaporation chamber. ) was used to monitor the evaporation rate of the Se source in the chamber. In the actual production process, whether a production cycle ends is mainly determined by the remaining amount of the least crucible 6 in the Se source.

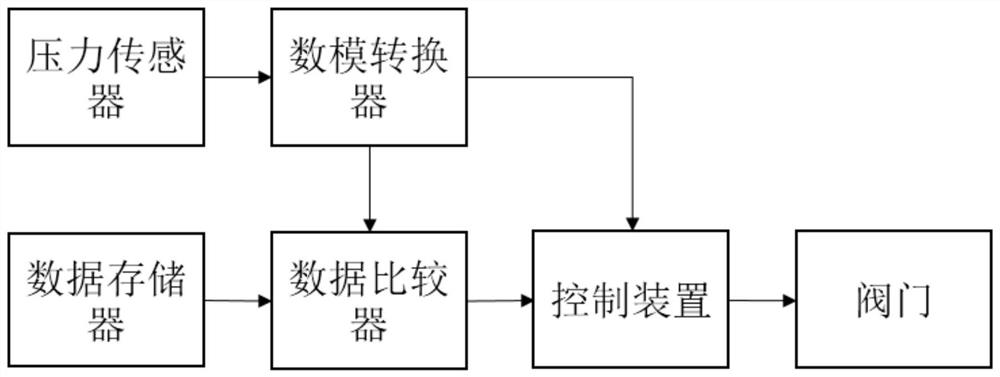

[0029] Such as figure 1 with figure 2 As shown, an evaporation material control system is provided in the embodiment of the present invention, including several crucibles 6, and each crucible 6 is used to hold evaporation materials; the bottom of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com