Preparation and application of montelukast sodium gel plaster

A technology of sodium gel patch and montelukast sodium, which is applied in the field of pharmaceutical preparations and achieves the effects of convenient use, comfortable application and good medication compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

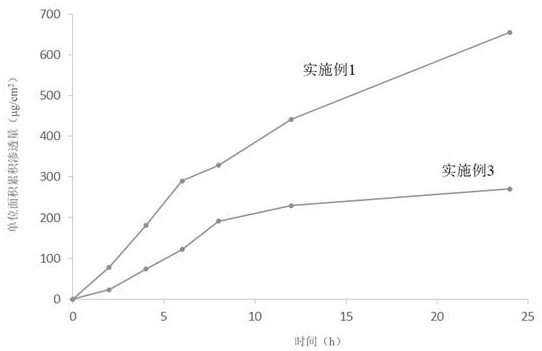

Examples

Embodiment 1

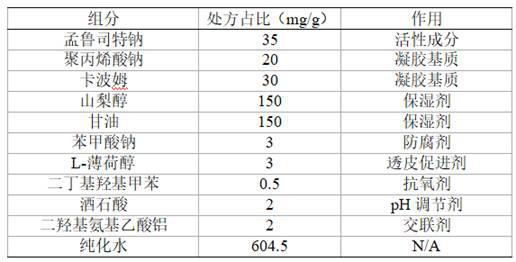

[0053] Prescription composition:

[0054]

[0055] Preparation Process:

[0056] A. Add purified water to the carbopol and tartaric acid of the prescribed amount to fully swell as phase A;

[0057] B. Mix the prescription amount of sodium polyacrylate, aluminum glycolate, sodium benzoate, talcum powder, dibutyl hydroxytoluene, L-menthol, add the prescription amount of glycerin and sorbitol, stir well, and put it at room temperature as Phase B.

[0058] C. Take another appropriate amount of purified water, add the prescribed amount of montelukast sodium to dissolve it, and use it as phase C. Mix phase A and phase C evenly, then slowly add to phase B, and continue to stir until a uniform drug-containing gel matrix is obtained. The non-woven fabric is used as the backing layer, and the PET polyester film coated with simethicone is used as the anti-adhesive layer, and the above substrates are coated, cut, packaged, etc. to obtain the montelukast sodium gel plaster.

Embodiment 2

[0060] Prescription composition:

[0061]

[0062] Preparation Process:

[0063] A. Add purified water to the carbopol and tartaric acid of the prescribed amount to fully swell as phase A;

[0064] B. Mix the prescribed amount of sodium polyacrylate, aluminum glycylate, talcum powder, and dibutyl hydroxytoluene, add the prescribed amount of glycerin and sorbitol, stir well, and put it at room temperature as phase B.

[0065] C. Take another appropriate amount of purified water, add the prescribed amount of montelukast sodium to dissolve it, and use it as phase C. Mix phase A and phase C evenly, then slowly add to phase B, and continue to stir until a uniform drug-containing gel matrix is obtained. The non-woven fabric is used as the backing layer, and the PET polyester film coated with simethicone is used as the anti-adhesive layer, and the above substrates are coated, cut, packaged, etc. to obtain the montelukast sodium gel plaster.

Embodiment 3

[0067] Prescription composition:

[0068]

[0069] Preparation Process:

[0070] A. Add purified water to the carbopol and tartaric acid of the prescribed amount to fully swell as phase A;

[0071] B. Mix the prescribed amount of sodium polyacrylate, aluminum glycylate, sodium benzoate, talcum powder, and dibutyl hydroxytoluene, add the prescribed amount of glycerin and sorbitol, stir evenly, and put it at room temperature as phase B.

[0072] C. Take another appropriate amount of purified water, add the prescribed amount of montelukast sodium to dissolve it, and use it as phase C. Mix phase A and phase C evenly, then slowly add to phase B, and continue to stir until a uniform drug-containing gel matrix is obtained. The non-woven fabric is used as the backing layer, and the PET polyester film coated with simethicone is used as the anti-adhesive layer, and the above substrates are coated, cut, packaged, etc. to obtain the montelukast sodium gel plaster.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com