Easily degradable environment-friendly ceramic material and preparation method thereof

A ceramic material and easy-to-degrade technology, which is applied in the production of ceramic materials, clay products, applications, etc., can solve the problems of toughness and easy-to-degradability that need to be improved, achieve a significant effect of easy-degradability, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The material is in parts by weight, including the following substances: 20 parts of crop straw, 15 parts of kaolin, 5 parts of glass fiber, 6 parts of diatomaceous earth, 6 parts of aluminum oxide, 5 parts of carbon fiber, 6 parts of boric acid, cubic nitride 3 parts of boron, 5 parts of thorium dioxide, 6 parts of dibutyl terephthalate, 17 parts of deionized water, and 6 parts of silicon carbide.

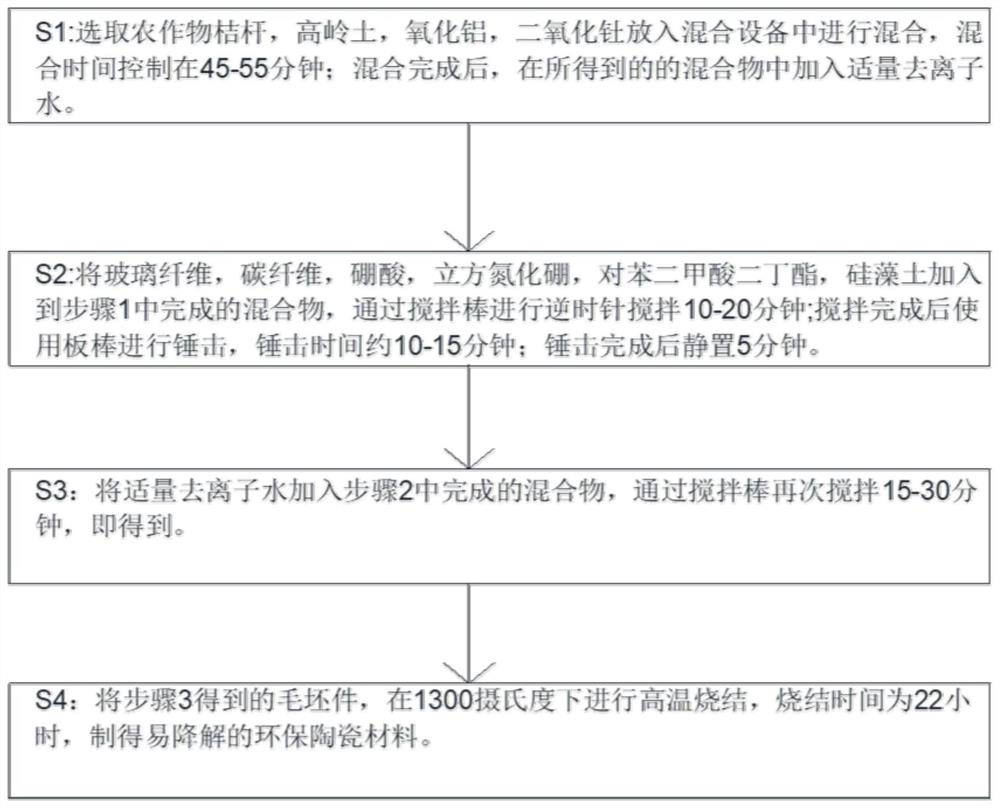

[0028] The preparation method of the easily degradable environment-friendly ceramic material, such as figure 1 shown, including the following steps:

[0029] S1: Select crops, kaolin, alumina, and thorium dioxide and put them into a mixing device for mixing. The mixing time is controlled at 45-55 minutes; after the mixing is completed, add an appropriate amount of deionized water to the obtained mixture.

[0030] S2: Add glass fiber, carbon fiber, boric acid, cubic boron nitride, dibutyl terephthalate, and diatomaceous earth to the mixture completed in step 1, and stir coun...

Embodiment 2

[0035] The material is in parts by weight, including the following substances: 15 parts of crop straw, 15 parts of kaolin, 6 parts of glass fiber, 6 parts of diatomaceous earth, 5 parts of aluminum oxide, 5 parts of carbon fiber, 5 parts of boric acid, cubic nitride 6 parts of boron, 7 parts of thorium dioxide, 7 parts of dibutyl terephthalate, 17 parts of deionized water, and 6 parts of carbonization.

[0036] The preparation method of the easily degradable environment-friendly ceramic material, such as figure 1 shown, including the following steps:

[0037] S1: Select crops, kaolin, alumina, and thorium dioxide and put them into a mixing equipment for mixing. The mixing time is controlled at 45-55 minutes; after the mixing is completed, add an appropriate amount of deionized water to the obtained mixture.

[0038] S2: Add glass fiber, carbon fiber, boric acid, cubic boron nitride, dibutyl terephthalate, and diatomaceous earth to the mixture completed in step 1, and stir cou...

Embodiment 3

[0043] The material is in parts by weight, including the following substances: 16 parts of crop straw, 15 parts of kaolin, 6 parts of glass fiber, 5 parts of diatomaceous earth, 7 parts of aluminum oxide, 3 parts of carbon fiber, 6 parts of boric acid, cubic nitride 6 parts of boron, 7 parts of thorium dioxide, 6 parts of dibutyl terephthalate, 17 parts of deionized water, and 6 parts of silicon carbide.

[0044] The preparation method of the easily degradable environment-friendly ceramic material, such as figure 1 shown, including the following steps:

[0045]S1: Select crops, kaolin, alumina, and thorium dioxide and put them into a mixing equipment for mixing. The mixing time is controlled at 45-55 minutes; after the mixing is completed, add an appropriate amount of deionized water to the obtained mixture.

[0046] S2: Add glass fiber, carbon fiber, boric acid, cubic boron nitride, dibutyl terephthalate, and diatomaceous earth to the mixture completed in step 1, and stir co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com