Special fertilizer for houttuynia cordata and production system and production method thereof

A production system and special fertilizer technology, applied in application, phosphate fertilizer, fertilization equipment, etc., to achieve the effects of prolonging fertilizer efficiency, promoting production increase and quality improvement, and promoting absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

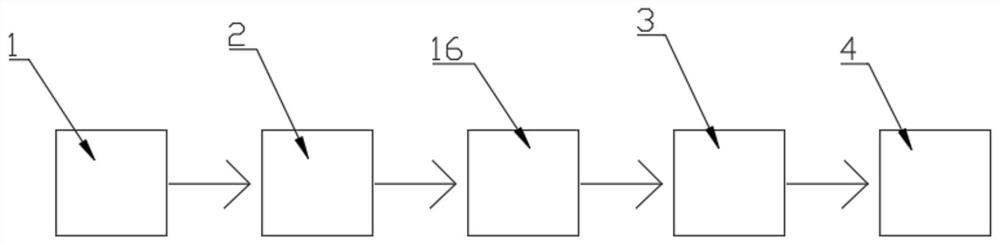

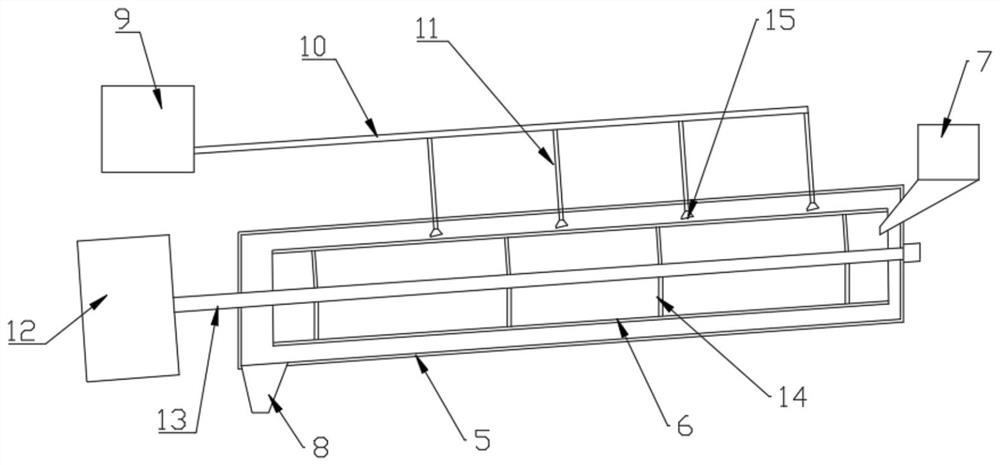

Method used

Image

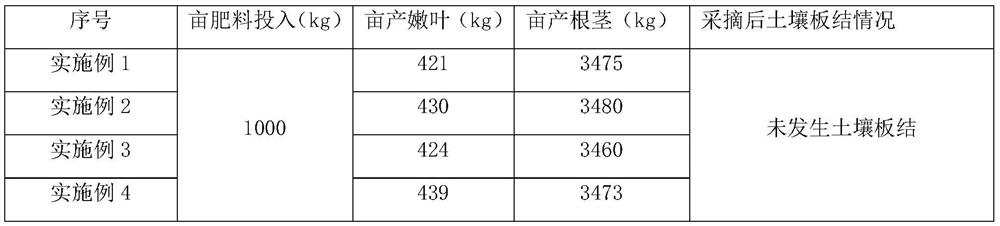

Examples

Embodiment 1

[0028] This embodiment provides a special fertilizer for Houttuynia cordata, which is processed through the following steps:

[0029] Put 1kg of superphosphate, 45kg of fermented organic matter and 38kg of filling matrix into the crusher and crush it into powder to obtain the primary mixture. Add 16kg of potassium fulvic acid solution (concentration 60%) to the primary mixture and introduce it into the granulator. Granulation, after granulation, the granular material with a water content of 30% is obtained, and then the granular material is sent to a dryer to reduce the water content to 20% to obtain a dry billet, which is cooled to 40°C and then introduced into the packaging machine. Start the motor at the same time and press 2.0X10 into the outer cylinder 8 CFU / g is fed into the bacterial solution, and the dry blank can be bagged and packaged to obtain a special fertilizer with a water content of 21.9% after being exported from the discharge pipe of the packaging machine;

...

Embodiment 2

[0034] This embodiment provides a special fertilizer for Houttuynia cordata, which is processed through the following steps:

[0035] Put 2kg of superphosphate, 48kg of fermented organic matter and 32kg of filling matrix into the crusher and crush it into powder to obtain the primary mixture. Add 18kg of potassium fulvic acid solution (concentration 60%) to the primary mixture and introduce it into the granulator. Granulation, after granulation, the granular material with a water content of 35% is obtained, and then the granular material is sent to a dryer to reduce the water content to 23% to obtain a dry billet, which is cooled to 40°C and then introduced into the packaging machine. Start the motor at the same time and press the 2.15X10 8 CFU / g is fed into the bacterial solution, and the dry blank can be bagged and packaged to obtain a special fertilizer with a water content of 25.1% after being exported from the discharge pipe of the packaging machine;

[0036] Among them,...

Embodiment 3

[0040] This embodiment provides a special fertilizer for Houttuynia cordata, which is processed through the following steps:

[0041] Put 3kg of superphosphate, 50kg of fermented organic matter and 27kg of filling matrix into the crusher and crush it into powder to obtain the primary mixture. Add 20kg of potassium fulvic acid solution (concentration 60%) to the primary mixture and introduce it into the granulator for further processing. Granulation, after granulation, the granular material with a water content of 40% is obtained, and then the granular material is sent to a dryer to reduce the water content to 25% to obtain a dry billet, which is cooled to 40°C and then introduced into the packaging machine. Start the motor at the same time and press the 2.3X10 8 CFU / g is fed into the bacterial solution, and the dry blank can be bagged and packaged to obtain a special fertilizer with a water content of 26.8% after being exported from the discharge pipe of the packaging machine;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com