Organic conjugated polymer as well as preparation method and application thereof

A technology of conjugated polymers and polymers, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of poor hydrogen production rate and achieve high dispersion, The effect of good thermodynamic stability and high light absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

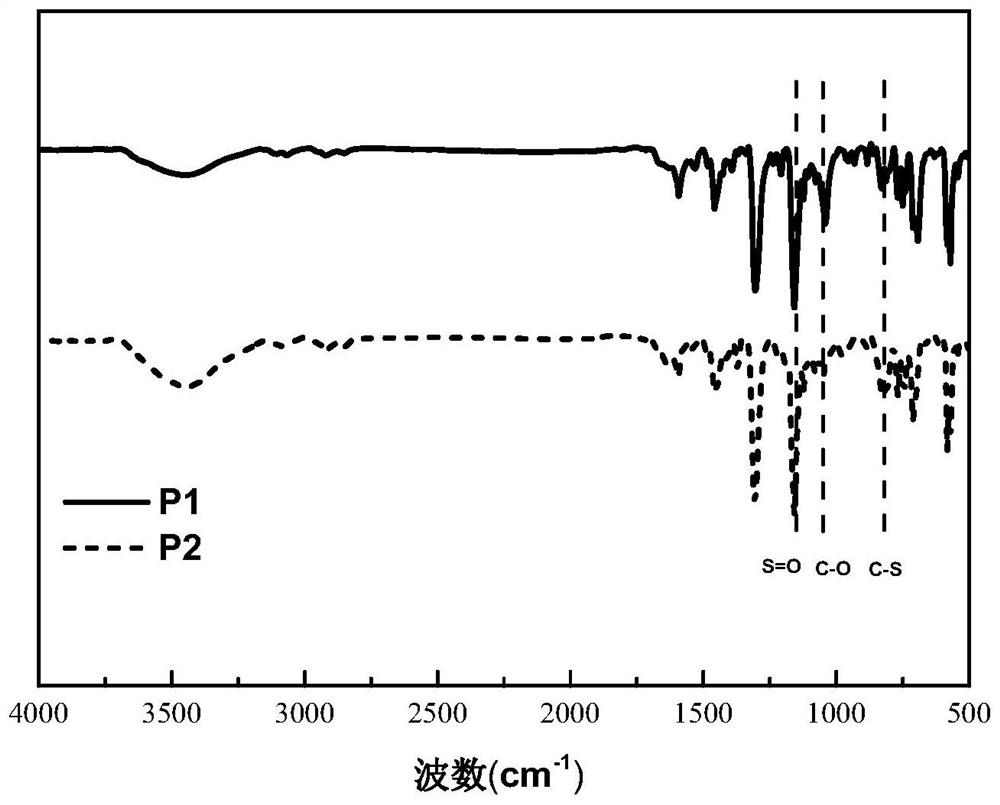

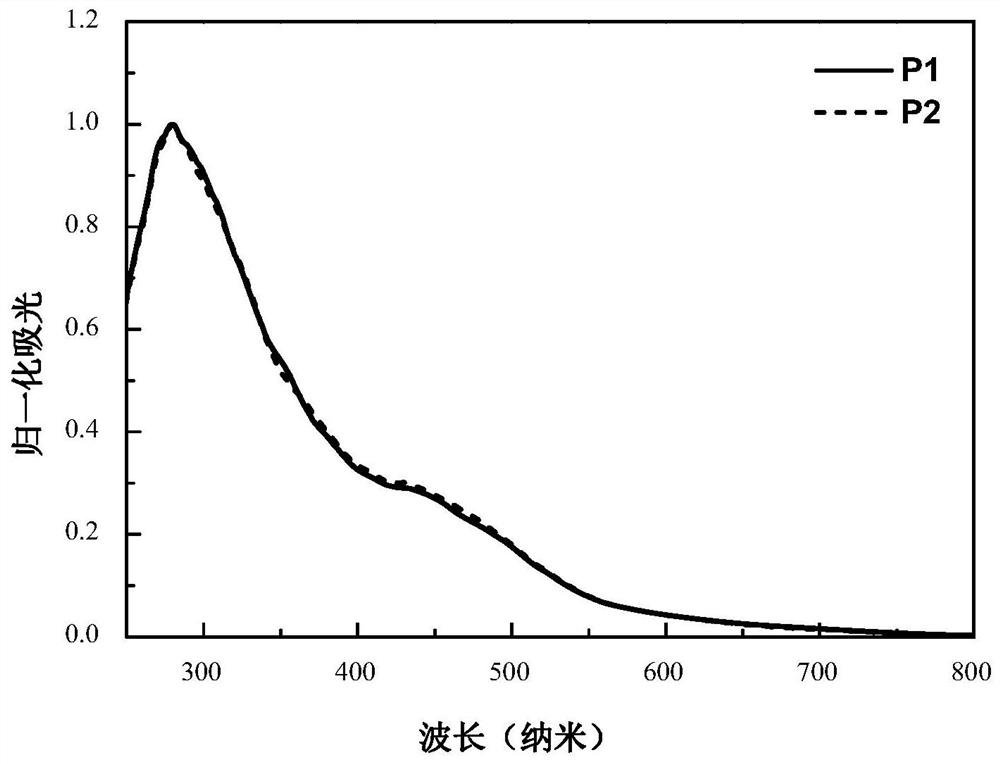

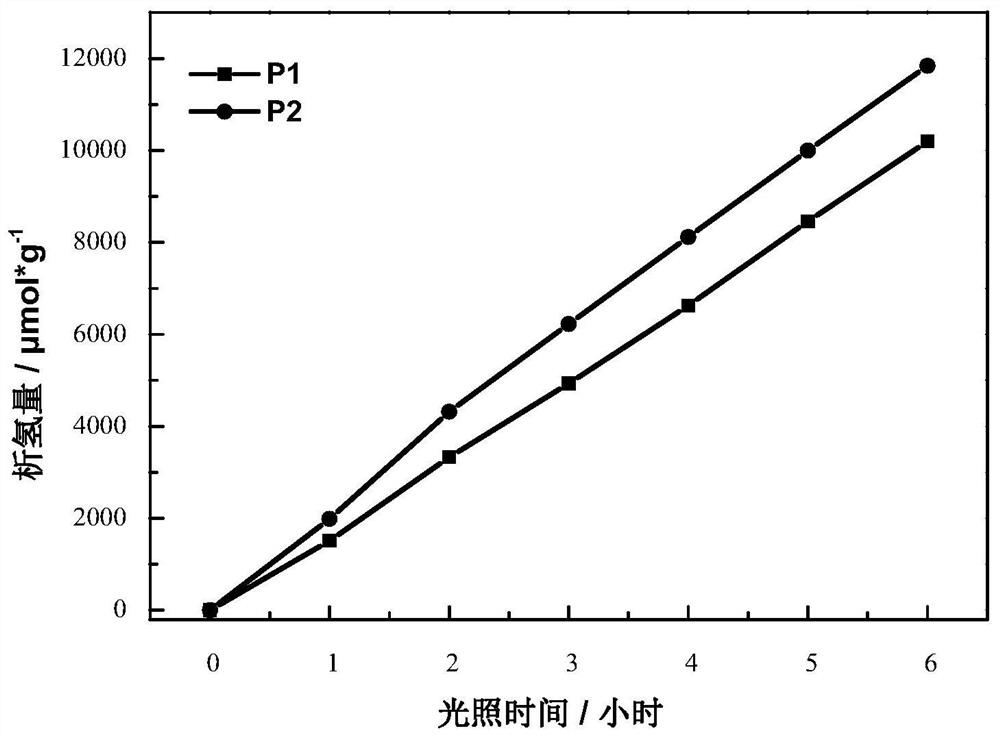

[0036] Synthesis of Polymer P1

[0037] The synthetic route is as follows:

[0038]

[0039] Accurately weigh monomer M1 (1.000mmol, 0.3741g) and monomer M2 (0.500mmol, 0.4131g), add it to a 48mL thick-walled pressure-resistant bottle, and add Pd (pph 3 ) 4 (0.025mmol, 29mg), K 2 CO 3 (2mol / L, 2.5mL) and DMF (15mL), sealed. Under the condition of 150°C, the reaction was protected from light for 48h. After the reaction solution was cooled to room temperature, it was dropped into a constantly stirring methanol solution, and filtered to obtain a crude product. The crude product was subjected to Soxhlet extraction with 100 mL of methanol and petroleum ether for 24 hours each, and the residual solid was washed with methanol and dried in vacuum for 24 hours to obtain a brown powdery product P1 with a degree of polymerization of 4.

[0040] The photocatalyst of this example is composed of copolymer P1.

Embodiment 2

[0042] Synthesis of Polymer P2

[0043] A representative synthetic route is as follows:

[0044]

[0045] Accurately weigh monomer M1 (1.000mmol, 0.3741g) and monomer M3 (0.500mmol, 0.4292g), add it to a 48mL thick-walled pressure bottle, and add Pd (pph 3 ) 4 (0.025mmol, 29mg), K 2 CO 3 (2mol / L, 2.5mL) and DMF (15mL), sealed. Under the condition of 150°C, the reaction was protected from light for 48h. After the reaction solution was cooled to room temperature, it was dropped into a constantly stirring methanol solution, and filtered to obtain a crude product. The crude product was subjected to Soxhlet extraction with 100 mL of methanol and petroleum ether for 24 hours each, and the residual solid was washed with methanol and dried in vacuum for 24 hours to obtain a yellow powdery product P2 with a degree of polymerization of 4.

[0046] The photocatalyst of this example is composed of copolymer P2.

Embodiment 3

[0048] The preparation method is the same as in Example 2, the difference is that the monomer of M1 is replaced by the monomer of A2 A P3 conjugated polymer having a degree of polymerization of 50 was obtained.

[0049] The photocatalyst of this example is composed of copolymer P3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com