TiO2@SnSexS2-x@SnO2 bifunctional composite structure and preparation method thereof

A composite structure, dual function technology, applied in selenium/tellurium compounds, chemical instruments and methods, elemental compounds other than selenium/tellurium, etc., can solve problems such as unfavorable light absorption catalysis, poor effect, poor effect , to achieve the effect of simple surface stability, improved light absorption capacity, good catalytic performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

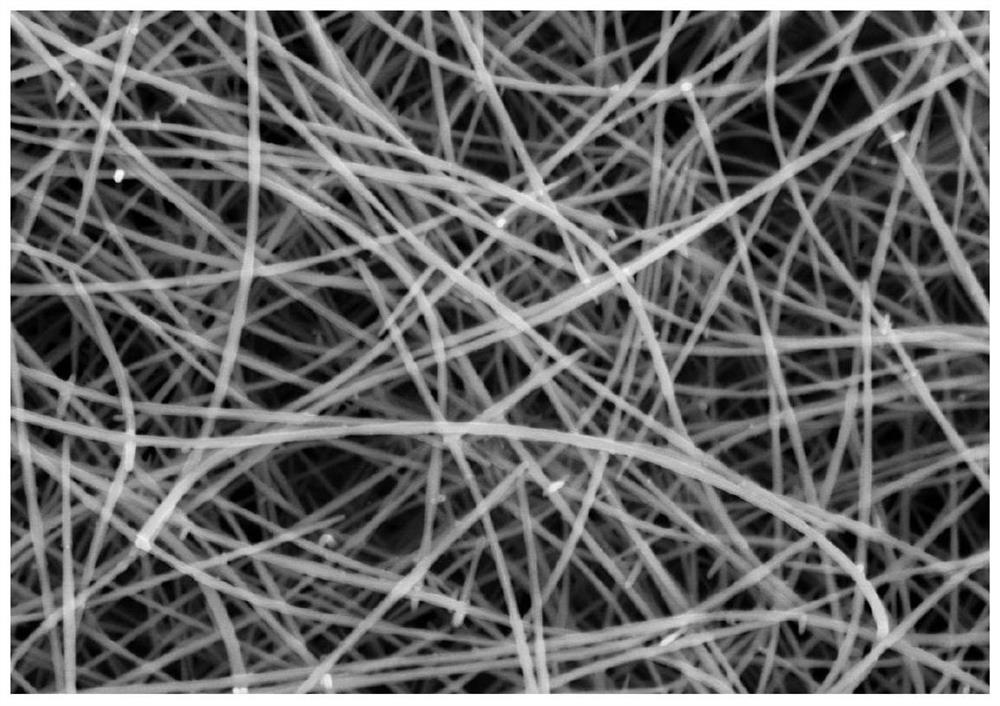

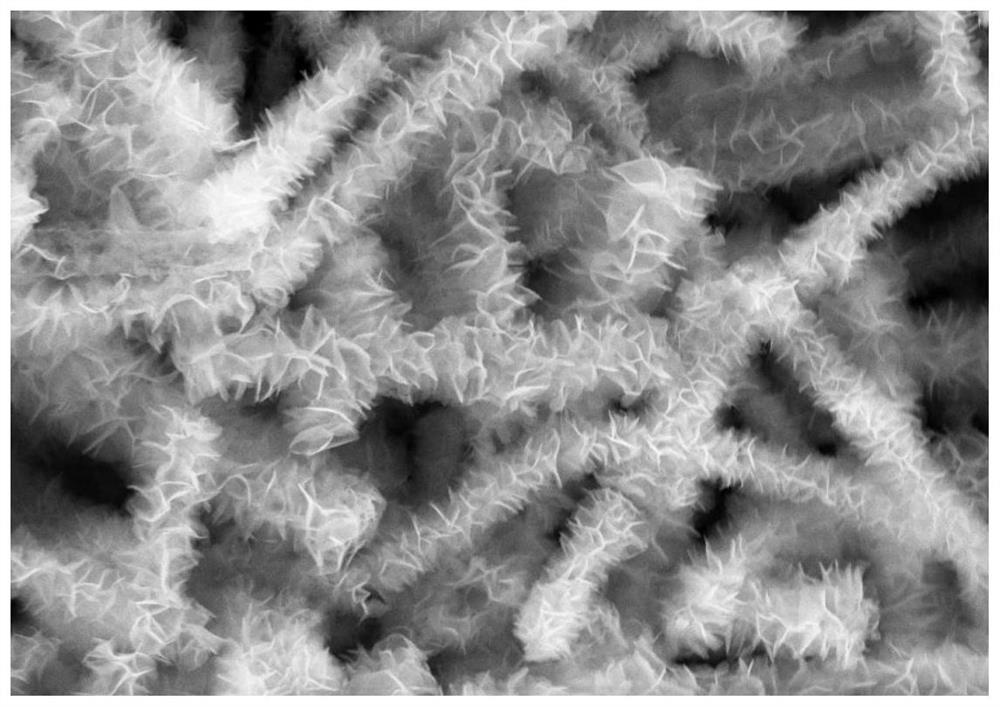

Embodiment 1

[0022] A kind of TiO 2 @SnSe x S 2-x @SnO 2 A method for preparing a bifunctional composite structure, the steps of which include: step 1, successively dissolving 1.02g of tetrabutyl titanate, 0.4g of PVP and 1.5ml of mineral oil in a mixed solution of 23.3ml of ethanol and 11.7ml of acetic acid, adding reagents each time It needs to be stirred for 60 minutes to form a mixed solution A; step 2, the mixed solution A is subjected to electrospinning treatment, the electrospinning parameters: the diameter of the needle head is 0.6mm, the distance between the needle tip and the substrate is 18cm, the voltage is 15KV; the temperature is 50°C ; Humidity is 25%; Step 3, after spinning, collect the fibers on the substrate and anneal at 600°C for 4h to obtain TiO 2 Nanotube; Step 4, 1.5mmol tin tetrachloride, 1:9 sodium selenite and thioacetamide are dissolved in the mixed solution of 33.5ml ethanol and 1.5ml acetic acid, then add TiO 2 Nanotubes to form a mixed solution B; Step 5, ...

Embodiment 2

[0027] The difference between this example and Example 1 is that the amount of tetrabutyl titanate in step 1 is changed to 1.36g, and the others are the same as in example 1, specifically as follows: step 1, sequentially mix 1.36g tetrabutyl titanate, 0.4g PVP and 1.5ml of mineral oil were dissolved in a mixed solution of 23.3ml of ethanol and 11.7ml of acetic acid, and each addition of reagents was stirred for 60 minutes to form a mixed solution A; step 2, the mixed solution A was subjected to electrospinning treatment, and the electrospinning parameters : The needle diameter is 0.6mm, the distance between the needle tip and the substrate is 18cm, the voltage is 15KV; the temperature is 50°C; the humidity is 25%; step 3, after spinning, collect the fibers on the substrate and anneal at 600°C for 4h , that is to get TiO 2 Nanotube; Step 4, 1.5mmol tin tetrachloride, 1:9 sodium selenite and thioacetamide are dissolved in the mixed solution of 33.5ml ethanol and 1.5ml acetic aci...

Embodiment 3

[0029] The difference between this embodiment and Example 1 is that the amount of ethanol and acetic acid in Step 1 is changed to 28ml and 7ml respectively, and others are the same as in Example 1, specifically as follows: Step 1, successively add 1.02g tetrabutyl titanate, 0.4g PVP Dissolve 1.5ml of mineral oil in a mixed solution of 28ml of ethanol and 7ml of acetic acid, and stir for 60 minutes each time the reagent is added to form a mixed solution A; step 2, carry out electrospinning treatment on the mixed solution A, electrospinning parameters: needle The diameter is 0.6mm, the distance between the needle tip and the substrate is 18cm, the voltage is 15KV; the temperature is 50°C; the humidity is 25%; step 3, after spinning, collect the fibers on the substrate and anneal at 600°C for 4h, namely Get TiO 2 Nanotube; Step 4, 1.5mmol tin tetrachloride, 1:9 sodium selenite and thioacetamide are dissolved in the mixed solution of 33.5ml ethanol and 1.5ml acetic acid, then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com