Preparation and application of Ag-doped CdSe nanosheet photocatalytic material for uranium reduction separation

A photocatalytic material and nanosheet technology, which can be used in catalyst activation/preparation, reduced water/sewage treatment, physical/chemical process catalysts, etc. and use, improve the light absorption capacity, improve the effect of the conduction band position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

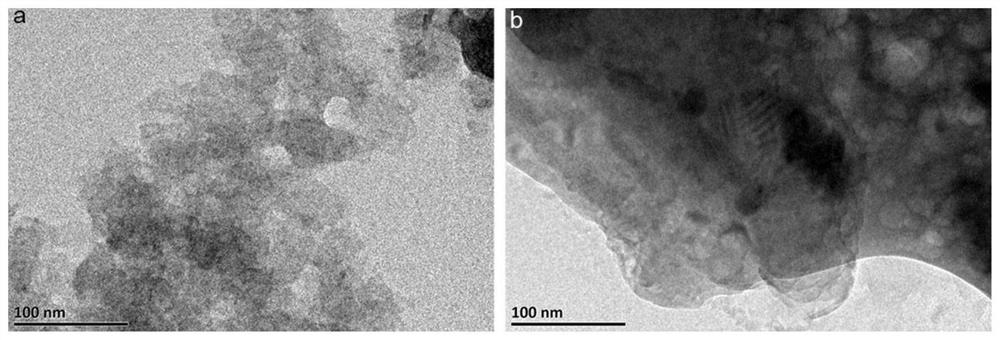

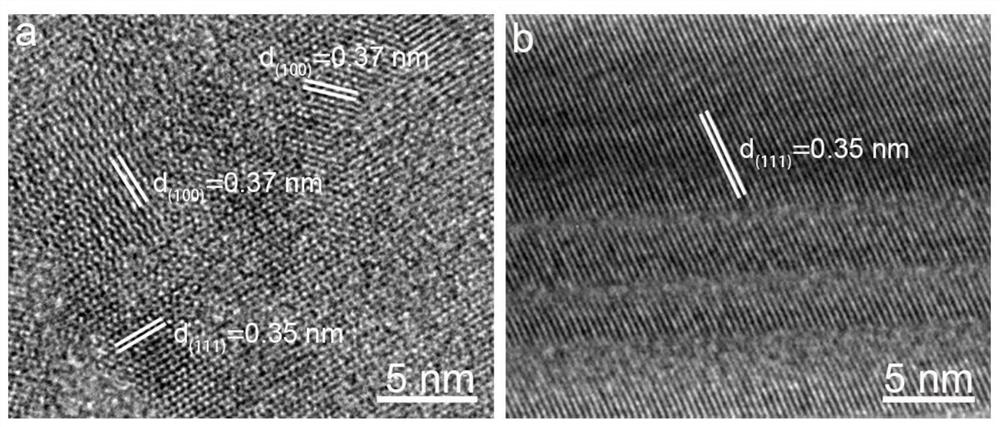

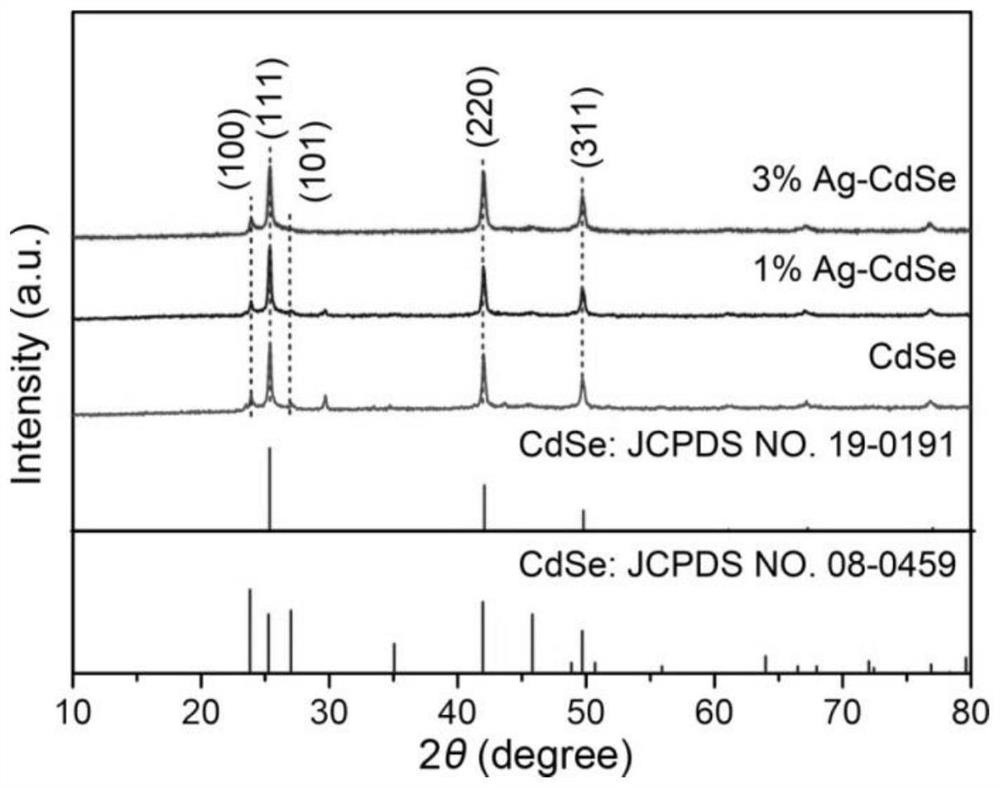

Image

Examples

Embodiment 1

[0040] A preparation method of Ag-doped CdSe nanosheet photocatalytic material for uranium reduction separation, comprising the following steps:

[0041] Step 1, 1.485mmol CdCl 2 2.5H 2 O and 0.015 mmol AgNO 3 The mixed powder was mixed with the first mixed solvent of 5mL octylamine and 5mL oleylamine, heated to 120°C, reacted for 2 hours, and naturally cooled to room temperature to obtain a reaction solution;

[0042]Step 2. At room temperature, mix 4.5mmol of Se powder with a second mixed solvent of 2.5mL of octylamine and 2.5mL of oleylamine to obtain a Se precursor solution;

[0043] Step 3. Add the Se precursor solution in step 2 to the reaction solution in step 1, then heat to 95 ° C, react for 16 hours, cool to room temperature, and wash the obtained precipitate with chloroform solution for 3 times, and then remove the precipitate Mix with 30mL0.1mol / L hexadecyltrimethylammonium bromide solution, and then sonicate for 60min, then wash the precipitate with ethanol sev...

Embodiment 2

[0045] A preparation method of Ag-doped CdSe nanosheet photocatalytic material for uranium reduction separation, comprising the following steps:

[0046] Step 1, 1.47mmol CdCl 2 2.5H 2 O and 0.03 mmol AgNO 3 The mixed powder was mixed with the first mixed solvent of 5mL octylamine and 5mL oleylamine, heated to 120°C, reacted for 2 hours, and naturally cooled to room temperature to obtain a reaction solution;

[0047] Step 2. At room temperature, mix 4.5mmol of Se powder with a second mixed solvent of 2.5mL of octylamine and 2.5mL of oleylamine to obtain a Se precursor solution;

[0048] Step 3. Add the Se precursor solution in step 2 to the reaction solution in step 1, then heat to 95 ° C, react for 16 hours, cool to room temperature, and wash the obtained precipitate with chloroform solution for 3 times, and then remove the precipitate Mix with 30mL0.1mol / L hexadecyltrimethylammonium bromide solution, and then sonicate for 60min, then wash the precipitate with ethanol seve...

Embodiment 3

[0050] A preparation method of Ag-doped CdSe nanosheet photocatalytic material for uranium reduction separation, comprising the following steps:

[0051] Step 1, 1.47mmol CdCl 2 2.5H 2 O and 0.03 mmol AgNO 3 The mixed powder was mixed with the first mixed solvent of 5mL octylamine and 5mL oleylamine, heated to 120°C, reacted for 2 hours, and naturally cooled to room temperature to obtain a reaction solution;

[0052] Step 2. At room temperature, mix 4.5mmol of Se powder with a second mixed solvent of 2.5mL of octylamine and 2.5mL of oleylamine to obtain a Se precursor solution;

[0053] Step 3. Add the Se precursor solution in step 2 to the reaction solution in step 1, then heat to 95 ° C, react for 16 hours, cool to room temperature, and wash the obtained precipitate with chloroform solution for 3 times, and then remove the precipitate Add 30mL of 0.1mol / L cetyltrimethylammonium bromide solution into the supercritical carbon dioxide reaction device, inject carbon dioxide i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com