Self-powered ultraviolet detection film with ZnO-based sandwich structure and preparation method of self-powered ultraviolet detection film

A sandwich and self-powered technology, applied in the field of microelectronics, can solve the problems of low sensitivity and large dark current, achieve process compatibility, reduce dark current, and improve light absorption ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

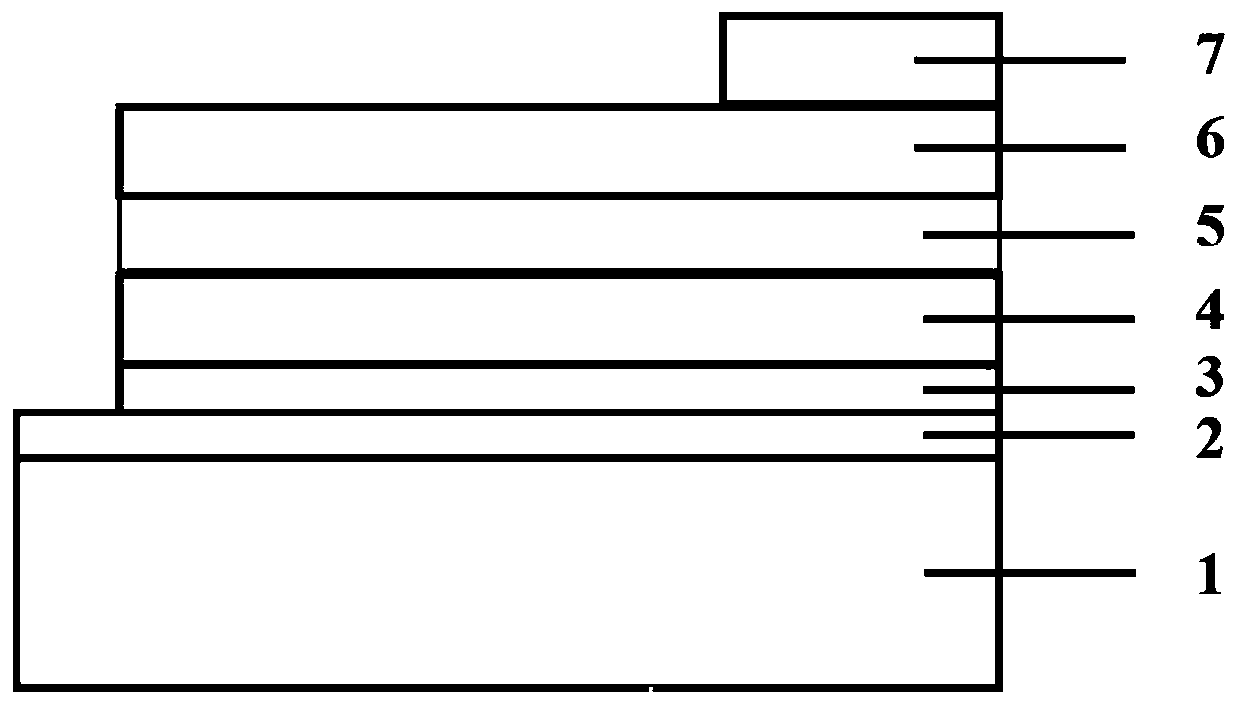

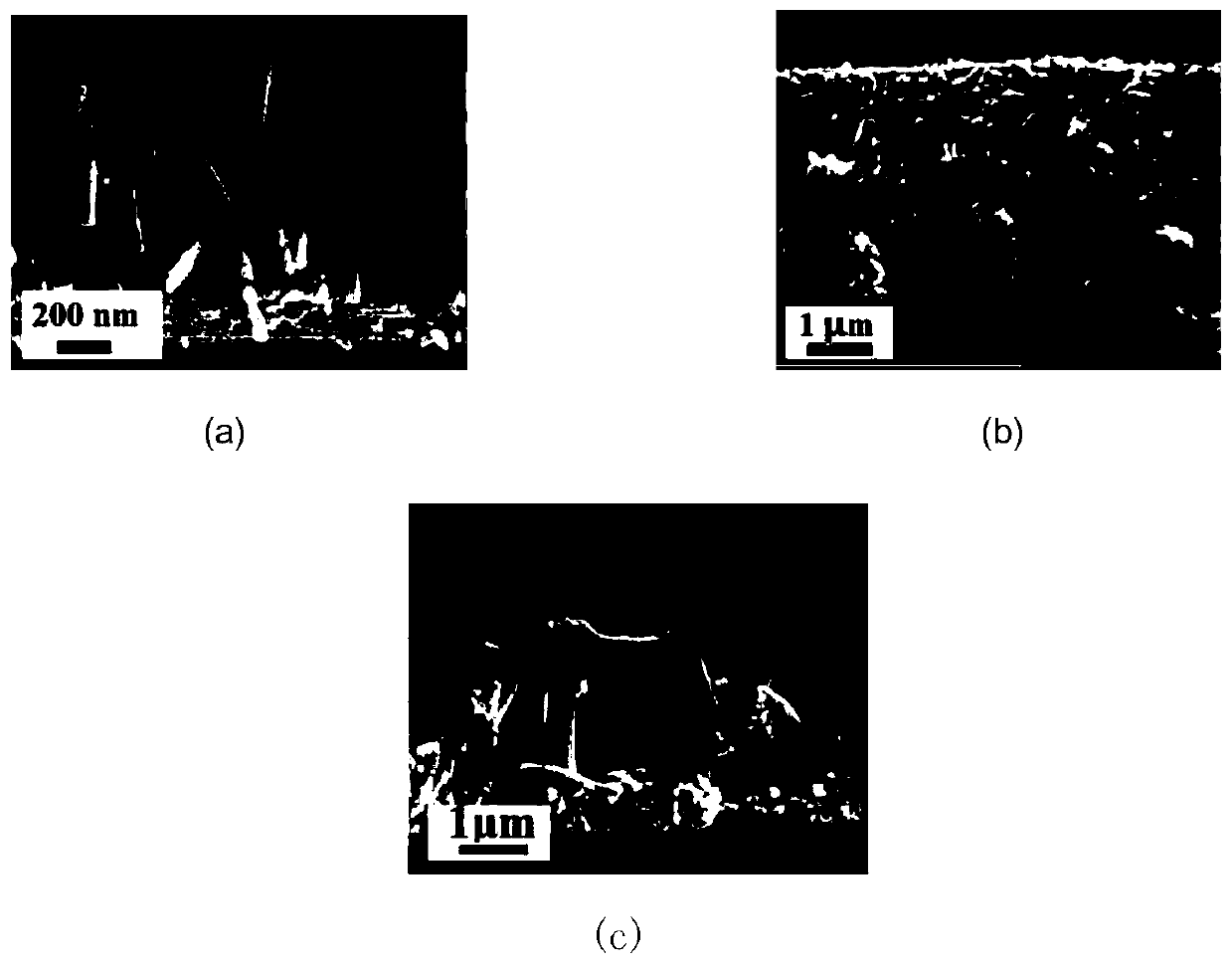

[0028] In this embodiment, the ZnO-based sandwich structure is a ZnO-NRs / CuO / PEDOT:PSS sandwich structure, and the preparation method of the self-powered ultraviolet detection film includes the following steps:

[0029] Step 1, using magnetron sputtering technology to prepare a ZnO seed layer on a glass substrate with an indium tin oxide electrode layer to obtain a substrate with a ZnO seed layer;

[0030] Specifically, in this step, the ITO glass substrate is cleaned, and the ITO glass substrate is ultrasonically cleaned with acetone, ethanol, and deionized water for 10 minutes; subsequently, the ITO substrate is blown dry with a nitrogen gas flow; Methods ZnO seed layer flakes were prepared on ITO glass substrate to obtain a substrate with ZnO seed layer.

[0031] Among them, the ZnO seed layer is deposited on the glass substrate with the indium tin oxide conductive layer by magnetron sputtering, specifically including:

[0032] Step 11, selecting a ZnO target with a purity...

Embodiment 2

[0052] The ZnO-based sandwich structure of this embodiment does not contain CuO film, but its preparation method is basically the same as that of Example 1, specifically: magnetron sputtering a ZnO seed layer film on a glass substrate with an indium tin oxide electrode layer, and oxidized The indium tin electrode layer was used as the bottom electrode, and then the ZnO nanocolumns (ZnO NRs) were prepared on the ZnO seed layer film by the hydrothermal method. The particles were deposited on the PEDOT:PSS layer as the upper electrode as the electrode, and finally the ZnO NRs-PEDOT:PSS ultraviolet detection film was obtained.

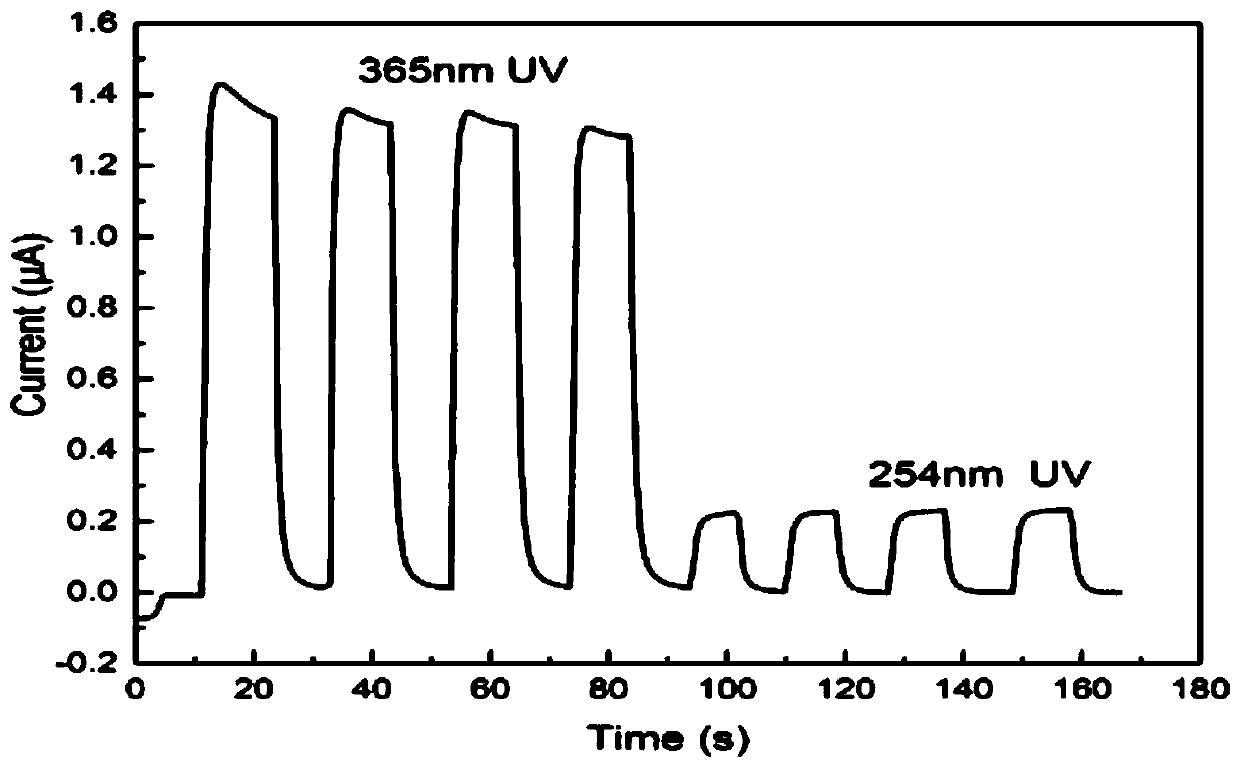

[0053] Figure 4 It is a real-time electrical and ultraviolet light response test chart for ZnO NRs-PEDOT:PSS ultraviolet detection film. Such as Figure 4 Shown: 1 is the I-T diagram of 365nm ultraviolet light irradiation and 10-second cycle off; 2 is the I-T diagram of 254nm ultraviolet light irradiation and 10-second cycle off. It can be seen that th...

Embodiment 3

[0055] The ZnO-based sandwich structure of this example is the same as that of Example 1, the difference is that the upper electrode is prepared by spraying gold on the ultraviolet detection film to explore the influence of different electrodes on the performance of the ultraviolet detection film, specifically: using the basic and implementation The same preparation method as in Example 1, magnetron sputtering ZnO seed layer thin film on ITO glass, using ITO conductive layer as the bottom electrode, followed by preparing ZnO NRs on the ZnO seed layer by hydrothermal method, and annealing the ZnO NRs The CuO thin film layer was deposited by spin coating, the PEDOT:PSS layer was scraped on the CuO thin film, dried at 60°C for 2 hours and cooled to room temperature naturally, and then gold was sprayed on the PEDOT:PSS layer to prepare the upper electrode.

[0056] Figure 5 It is the real-time electrical and ultraviolet light response test chart of ZnO NRs-CuO-PEDOT:PSS ultraviol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com