High-voltage electrostatic field-assisted self-assembly method and product for preparing high-crystalline and high-orientation regenerated cellulose materials

A high-voltage electrostatic field and regenerated cellulose technology is applied in the field of high-voltage electrostatic field-assisted self-assembly to prepare highly crystalline and highly oriented regenerated cellulose materials. The process is simple, the effect of realizing large-area production and broadening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

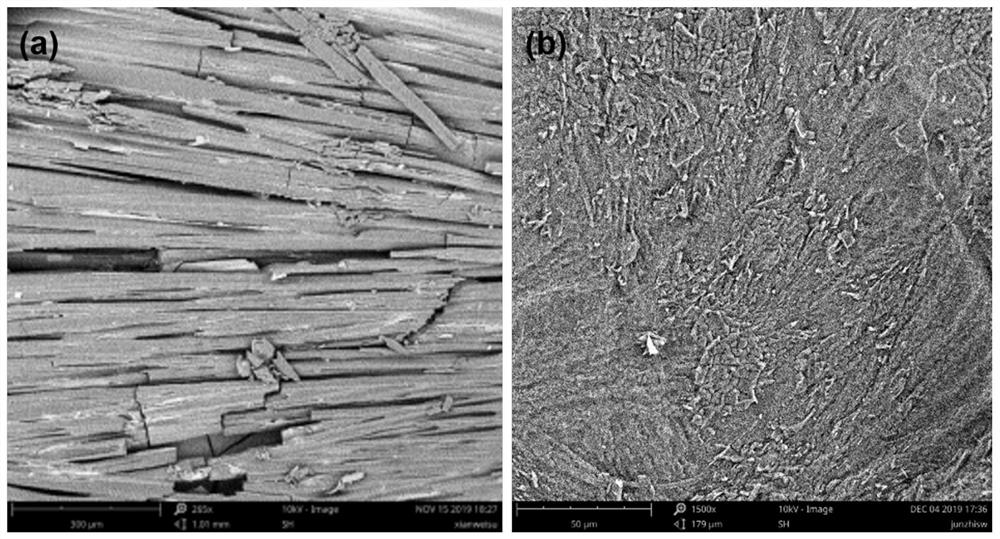

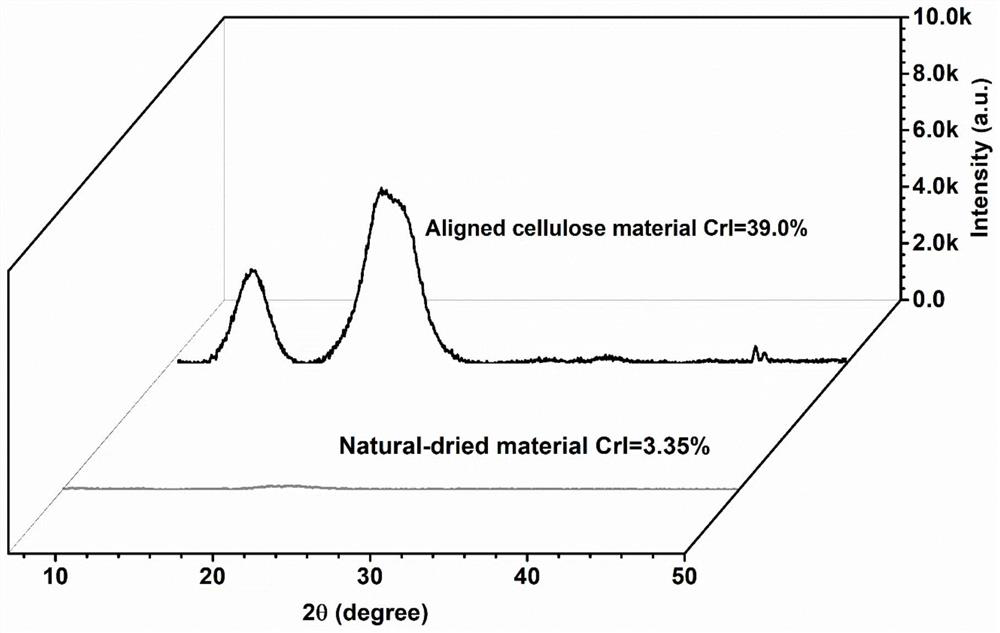

[0037] Take cellulose (viscosity average molecular weight M η =9.72×10 4 ) 4 grams, add 100 grams of 7wt% sodium hydroxide / 12wt% urea mixed aqueous solution (i.e. 7wt% sodium hydroxide, 12wt% urea), stir in an ice-water bath for 10 minutes, then freeze in a refrigerator for 3 hours, Take out and stir well to obtain a colorless and transparent solution. After filtering to remove a small amount of undissolved cellulose, scrape the film on the glass, and place it in a high-voltage electrostatic field. At this time, the electrostatic field voltage is 14kV, and the distance between the positive and negative electrode plates is 15cm. Wash it after the film is formed. Vacuum drying at 40°C to obtain regenerated cellulose material with high crystallinity and high orientation.

Embodiment 2

[0039] Take cellulose (viscosity average molecular weight M η =9.72×10 4 ) 4 grams, add 100 grams of 7wt% / 12wt% alkali urea aqueous solution, stir in an ice-water bath for 10 minutes, then freeze in a refrigerator for 3 hours, take out and stir well to obtain a colorless and transparent solution. After filtering to remove a small amount of undissolved cellulose, scrape the film on the glass and place it in a high-voltage electrostatic field. At this time, the electrostatic field voltage is 16kV, and the distance between the positive and negative electrode plates is 15cm. Wash it after the film is formed. It is a regenerated cellulose material with high crystallinity and high orientation, which is dried under vacuum at 40°C.

Embodiment 3

[0041] Take cellulose (viscosity average molecular weight M η =9.72×10 4 ) 4 grams, add 100 grams of 7wt% / 12wt% alkali urea aqueous solution, stir in an ice-water bath for 10 minutes, then freeze in a refrigerator for 3 hours, take out and stir well to obtain a colorless and transparent solution. After filtering to remove a small amount of undissolved cellulose, scrape the film on the glass and place it in a high-voltage electrostatic field. At this time, the electrostatic field voltage is 18kV, and the distance between the positive and negative electrode plates is 15cm. Wash it after the film is formed. Vacuum drying at 40°C to obtain regenerated cellulose material with high crystallinity and high orientation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com