Cellular and columnar combined structure coating used in marine environment and preparation method of cellular and columnar combined structure coating

A technology of combined structure and marine environment, applied in the direction of coating, metal material coating process, etc., can solve the problems of arc welding quality cannot be guaranteed, high laser manufacturing cost, complicated operation, etc., to enhance the solid solution strengthening effect and improve the shape. Core rate, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1: Powder Preparation

[0036] The raw material of the wear-resistant and corrosion-resistant coating is alloy powder, which is selected from metal powders such as Ni, Cr, Fe, Co, Mn, etc., and the particle size of the powder is 48-75 μm. The powder ratio is molar ratio, where the ratio of alloy powder in the first layer is Co:Cr:Fe:Ni:Mn=1:1:1:1:1, and the ratio of alloy powder in the second layer is Co: Cr:Fe:Ni:Mn:Ti:B 4 C=1:1:1:1:1:0.25:0.08, put the prepared metal powder in a three-dimensional mixer and mix for 24 hours.

[0037] Step 2: Substrate Surface Pretreatment

[0038] Before the cladding experiment, the substrate was cleaned with decontamination powder, followed by rough grinding with an angle grinder, fine grinding and leveling with sandpaper, and then ultrasonic cleaning of the substrate in absolute ethanol for 30 minutes to remove oil stains on the substrate and rust, and finally put it in an oven at 60°C for 2 hours.

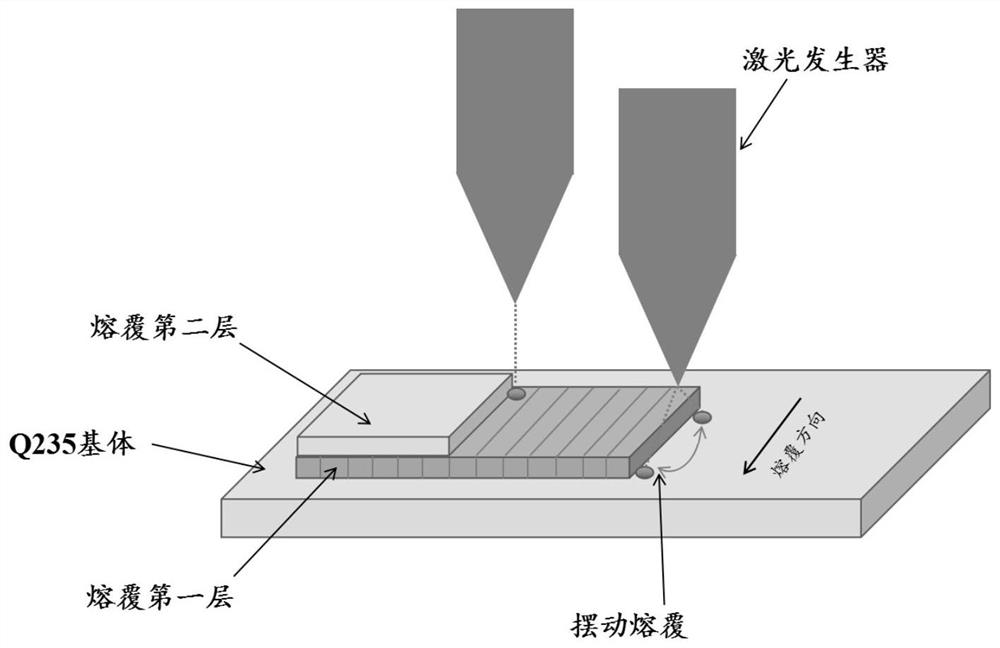

[0039] Step 3: Laser cla...

Embodiment 2

[0045] Step 1: Powder Preparation

[0046] The powder ratio is molar ratio, where the ratio of the alloy powder of the first layer is Co:Cr:Ni:Mn:Fe=1:1:1:1:1, and the ratio of the alloy powder of the second layer is Co:Cr :Fe:Ni:Mn:Ti:B 4 C=1:1:1:1:1:0.5:0.16, put the prepared metal powder in a three-dimensional mixer and mix for 24 hours.

[0047] Step 2: Substrate Surface Pretreatment

[0048] Before the cladding experiment, the substrate was cleaned with decontamination powder, followed by rough grinding with an angle grinder, fine grinding and leveling with sandpaper, and then ultrasonic cleaning of the substrate in absolute ethanol for 30 minutes to remove oil stains on the substrate and rust, and finally put it in an oven at 60°C for 2 hours.

[0049] Step 3: Laser swing cladding the first alloy layer

[0050] The laser cladding method is adopted, the laser power is 1200W, the scanning speed is 8mm / s, the spot diameter is 3mm, the overlap rate is 33%, the swing ampl...

Embodiment 3

[0054] Step 1: Powder Preparation

[0055] The powder ratio is molar ratio, where the ratio of the alloy powder of the first layer is Co:Cr:Ni:Mn:Fe=1:1:1:1:1, and the ratio of the alloy powder of the second layer is Co:Cr :Fe:Ni:Mn:Ti:B 4 C=1:1:1:1:1:1:0.33, put the prepared metal powder in a three-dimensional mixer and mix for 24 hours.

[0056] Step 2: Substrate Surface Pretreatment

[0057] Before the cladding experiment, the substrate was cleaned with decontamination powder, followed by rough grinding with an angle grinder, fine grinding and leveling with sandpaper, and then ultrasonic cleaning of the substrate in absolute ethanol for 30 minutes to remove oil stains on the substrate and rust, and finally put it in an oven at 60°C for 2 hours.

[0058] Step 3: Laser swing cladding the first alloy layer

[0059] The laser cladding method is adopted, the laser power is 1200W, the scanning speed is 8mm / s, the spot diameter is 3mm, the overlap rate is 33%, the swing amplit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com