A kind of ultra-soft anti-reverse osmosis kapok diaper material and preparation method thereof

A technology for diapers and kapok, applied in the field of sanitary materials, can solve the problems of easy reverse osmosis to the skin, insufficient biological safety, skin discomfort, etc. Excellent biosafety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

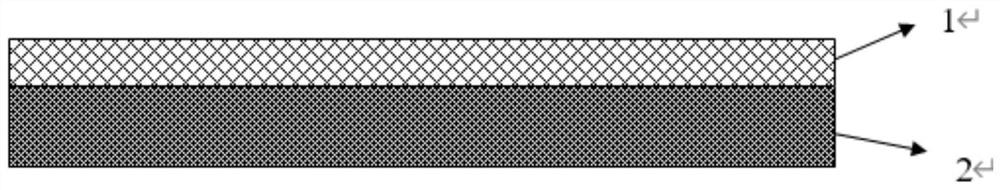

[0027] like figure 1 As shown, an ultra-soft anti-reverse osmosis kapok diaper material is composed of a surface layer kapok / viscose spunlace fiber web 1 with a large aperture that is conducive to liquid penetration and is not easy to reverse osmosis, and a small aperture and can achieve rapid liquid absorption. The absorbent layer of viscose / wood pulp wet-laid fiber web 2 is composited, and the weight of the surface layer is 15g / m2 2 , the weight of the absorption layer is 35g / m 2 , It has a flexible entanglement and stable pore structure with a large upper pore size and a small lower pore size, large liquid absorption power, small reverse osmosis power, and excellent biological safety.

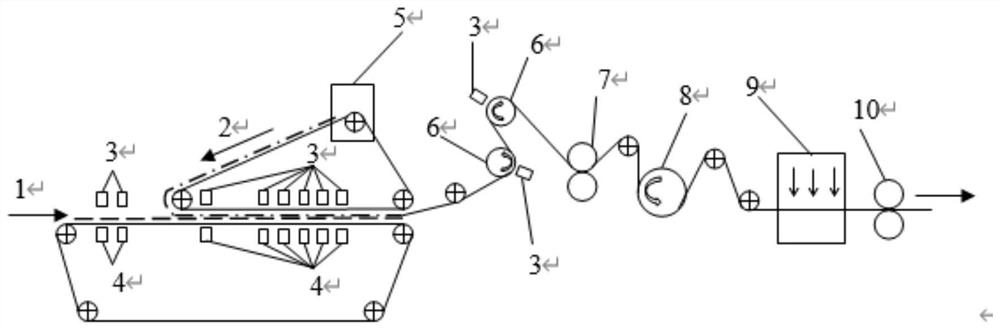

[0028] like figure 2 As shown, the preparation method of the ultra-soft anti-reverse osmosis kapok diaper material comprises the following steps:

[0029] (1) Pre-wet the kapok fiber with a mass fraction of 40%, a thickness of 0.9-1.8D and a length of 16-32mm to prevent the kapok from sc...

Embodiment 2

[0034] like figure 1 As shown, an ultra-soft anti-reverse osmosis kapok diaper material is composed of a surface layer kapok / viscose spunlace fiber web 1 with a large aperture that is conducive to liquid penetration and is not easy to reverse osmosis, and a small aperture and can achieve rapid liquid absorption. The absorbent layer of viscose / wood pulp wet-laid fiber web 2 is composited, and the surface layer weight is 10 g / m 2 , the weight of the absorbing layer is 40 g / m 2 , It has a flexible entanglement and stable pore structure with a large upper pore size and a small lower pore size, large liquid absorption power, small reverse osmosis power, and excellent biological safety.

[0035] like figure 2As shown, the preparation method of the ultra-soft anti-reverse osmosis kapok diaper material comprises the following steps:

[0036] (1) Pre-wet the kapok fibers with a mass fraction of 50%, a thickness of 0.9-1.8D and a length of 16-32mm to prevent the kapok from scatterin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com