Heat-preservation and fireproof external wall board for ultra-low-energy-consumption building and construction method of external wall board

A construction method and construction technology, applied in the direction of building insulation materials, heat preservation, fire protection, etc., can solve the problems of excessive thickness, shedding, and collapse of rock wool, and achieve the effects of reducing the thickness of rock wool, optimizing the indoor environment, and reducing indoor noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] To fully understand the purposes of the present invention, the present invention will be described in detail by the following specific embodiments, but the present invention is not limited thereto.

[0024] The construction method of an ultra-low energy consumption building provided by the present invention is carried out as follows:

[0025] Step 1: Install the aerated concrete wall panel to connect the wall panel to the main structure.

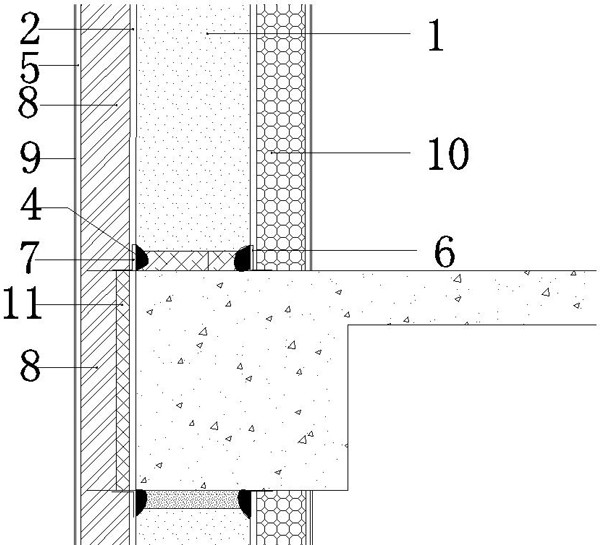

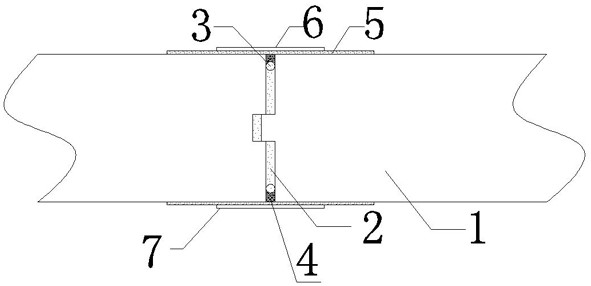

[0026] Step 2: The sewing between the aerated concrete plate 1 and the gap between the aerated concrete panel 1 and the structural beam sheet are filled with the filler 3 and seal, and the plate mortar is smooth on both sides of the plate of the aerated concrete slab 1. Washed surface mortar 5 width ≥ 100mm. Washed mortar 5 After drying, the coated mortar 5 outer surface bonding waterproof membrane 5, outdoor wipe mortar 5 bonding waterproof breathable film 7, such as figure 2 Indicated. The filler 3 is a PE rod or a polyurethane foamer, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com