Nano single hole based on capillary tip, preparation method and application thereof

A capillary, cutting-edge technology, applied in the field of nanopores, can solve the problems of difficult ion current blockage events, judging molecular structure information, etc., and achieve the effects of high application value, simple raw materials, and mild conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The method for preparing nano single hole of the present invention, comprises the steps:

[0043] (1) Preparation of capillary tip: The instrument used is the P-2000 needle pulling instrument of SUTTER Company in the United States, and the capillary is a quartz capillary (QF: 100-70-10, OD: 1.00mm, ID: 0.70mm) of SUTTER Company, the total length It is 10cm. Set parameters as heat=750, filament=3, velocity=40, delay=175, pull=190.

[0044] The diameter of the tip of the capillary prepared under the above conditions with this specification capillary is 60nm, such as Figure 4As shown in A. The capillary has a total length of 2 cm and the rear end is macroscopic.

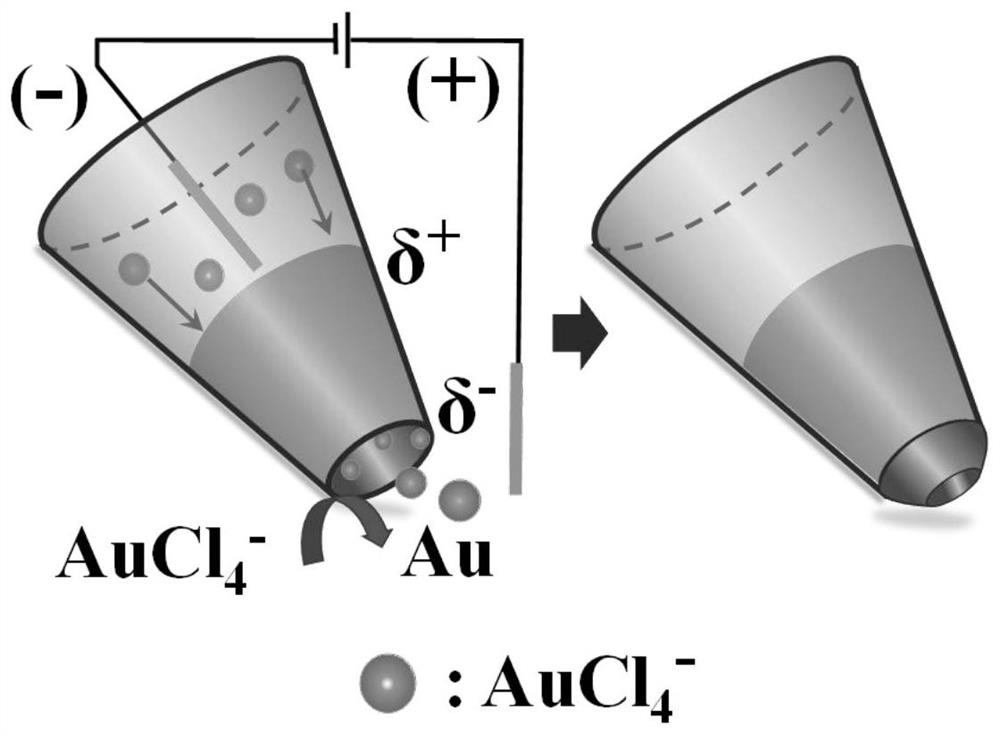

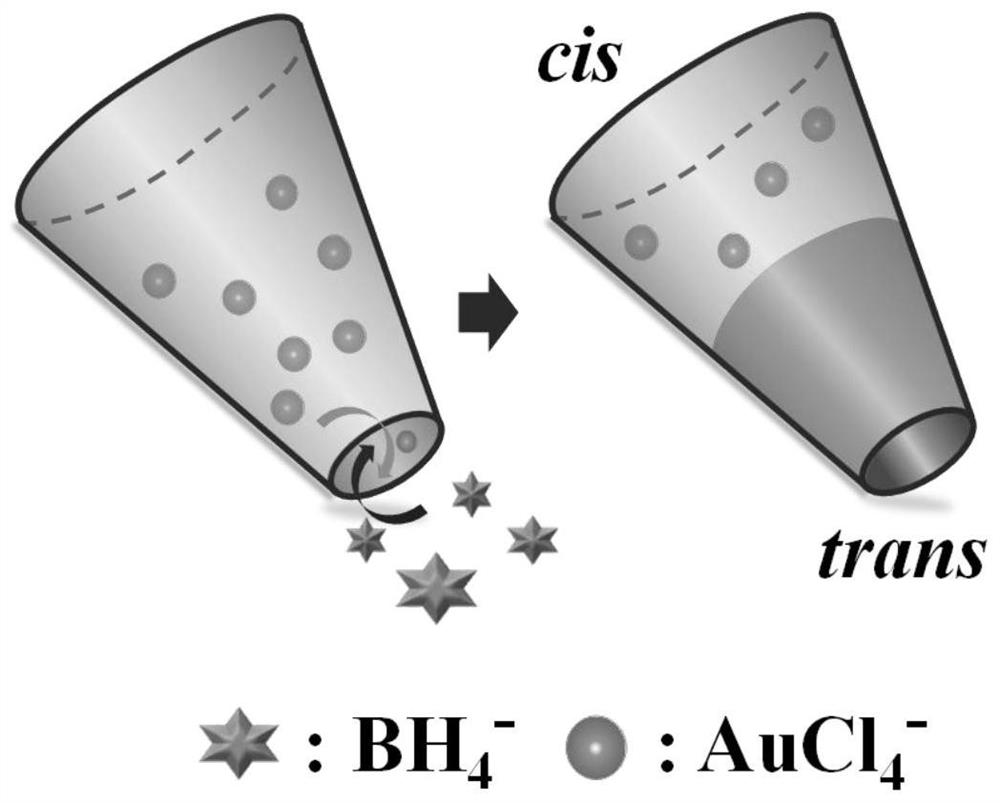

[0045] (2) Preparation of deposition layer by chemical reduction method: inject 100mM chloroauric acid solution into the capillary, and immerse the tip of the capillary in 5mM NaBH at room temperature (25±1°C) 4 Carry out chemical reduction in pure ethanol solution, react for 1 to 2 minutes, and deposit a ta...

Embodiment 2

[0052] (1) By adjusting the parameters, a quartz capillary with a length of 10 cm and a tip diameter of 20 nm was prepared.

[0053] (2) Preparation of deposition layer by chemical reduction method: inject 200mM chloroauric acid solution into the capillary, at room temperature (25±1°C), immerse the tip of the capillary in 100mM ascorbic acid solution for chemical reduction, react for 10min, in the capillary tip A conical gold deposit is deposited.

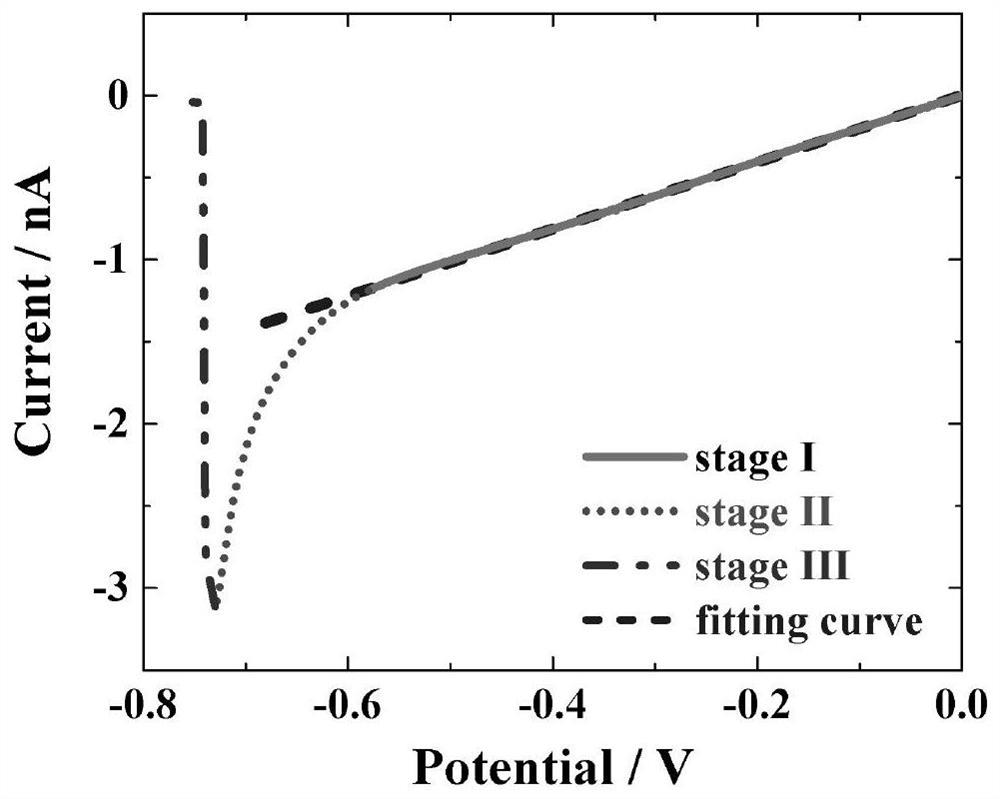

[0054] (3) Preparation of nano single hole: inject 200mM silver nitrate solution into the capillary, then immerse the tip of the capillary in the 5mM silver nitrate solution, insert a platinum wire electrode inside and outside the tube respectively, as working electrode and counter electrode, said The working electrode and the counter electrode were directly applied with a voltage of -1 V by the current-time method of constant voltage. The gold deposition layer formed by chemical reduction is used as a bipolar electrode, and the e...

Embodiment 3

[0057] (1) By adjusting the parameters, a glass capillary with a length of 15 cm and a tip diameter of 200 nm was prepared.

[0058] (2) Electron beam evaporation technology is used to deposit a silver layer on the inner wall of the tip of the capillary.

[0059] (3) Preparation of nanometer single hole: inject 100mM chloroauric acid solution into the capillary, then immerse the tip of the capillary in 20mM chloroauric acid solution, insert a platinum wire electrode inside and outside the tube respectively as the working electrode and the counter electrode, The working electrode and the counter electrode are directly applied with a voltage of 0 to -5V by linear sweep voltammetry with a sweep rate of 200mV / s (the instrument used is CHI-830B, CH Instrument Ins). The silver deposition layer is used as a bipolar electrode, and the electrochemical reduction is terminated after the characteristic current drops, and a more uniform single-pore gold is finally reduced at the tip. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Tip diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com