Semiconductor laser for 50: 50 split optical fiber coupling output, and method

A fiber coupling and semiconductor technology, applied in the field of lasers, can solve the problems that the position deviation of the coupler is easy to affect the coupling efficiency and the beam quality, and limit the application, so as to improve the accuracy of data, increase the stability and reliability, and optimize the coupling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

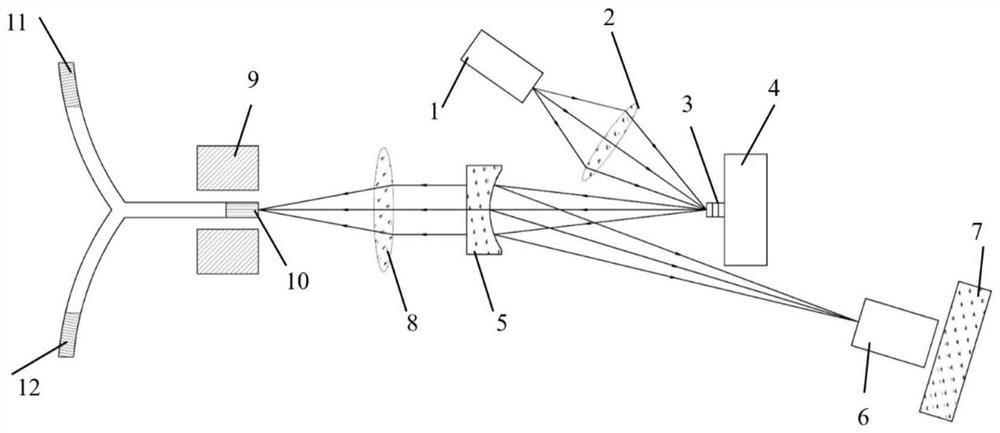

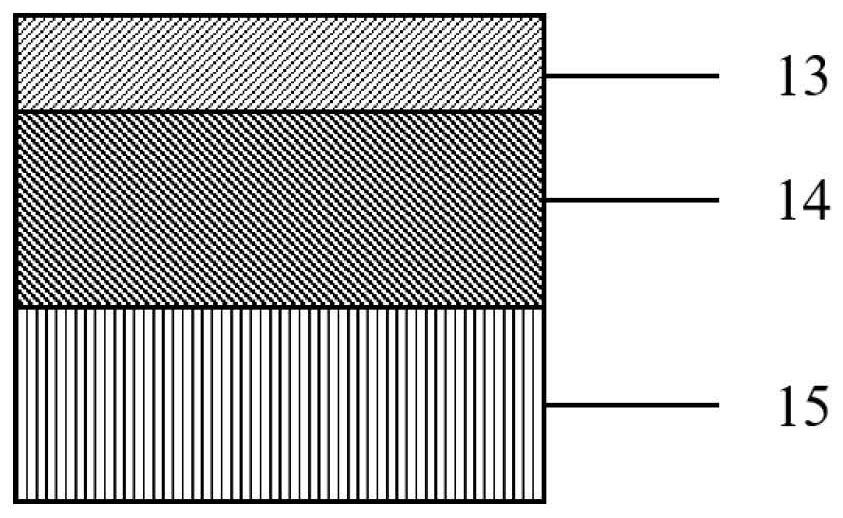

[0024] This embodiment provides a 50:50 split-fiber coupled output semiconductor laser, such as figure 1 As shown, it includes pump laser generator 1, focusing lens 2, semiconductor gain chip 3, output coupling mirror 5, frequency doubling crystal 6, end mirror 7, coupling lens 8, splitting fiber input port 10, splitting fiber output port One 11 and splitting fiber output end two 12; the included angle between the midline of the emission end of the pump laser generator 1 and the end face of the semiconductor gain chip 3 is 45°, and the focusing lens 2 is located at the pump laser generator 1 between the transmitting end of the semiconductor gain chip 3 and the output coupling mirror 5; On the way, the frequency doubling crystal 6 is located between the end mirror 7 and the output coupling mirror 5; the coupling lens 8 is located on the transmission optical path of the output coupling mirror 5, and the splitting fiber input end 10 is opposite to the output end of the coupling l...

Embodiment 2

[0031] This embodiment provides a working method of the semiconductor laser described in Embodiment 1, and the specific process is:

[0032] The pump laser generator 1 emits laser light with a wavelength of 808nm, which is converged by the focusing lens 2 and focused at 45° on the semiconductor gain chip 3, and the semiconductor gain chip 3 generates laser light with a wavelength of 1010nm.

[0033] It should be noted that, because the end face of the semiconductor gain chip 3 has a highly reflective mirror region (Bragg reflector structure), the reflectivity to laser light with a wavelength of 1010nm is greater than 99.9%, and forms a 1010nm resonant cavity with its output window region, so the output wavelength of 1010nm laser.

[0034]The 1010nm laser light is reflected by the output coupling mirror 5 and converged onto the frequency doubling crystal 6, and the laser light with a wavelength of 505nm is generated by the frequency doubling effect of the frequency doubling cry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com