Production process of LED display screen

A technology of LED display and production process, which is applied in the direction of instruments, electrical components, printed circuits, etc. It can solve the problems of poor coating hardness, easy scratching, and resistance to friction, etc., to increase smoothness and feel, and improve leveling Reasonable performance and production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained below in conjunction with specific embodiments.

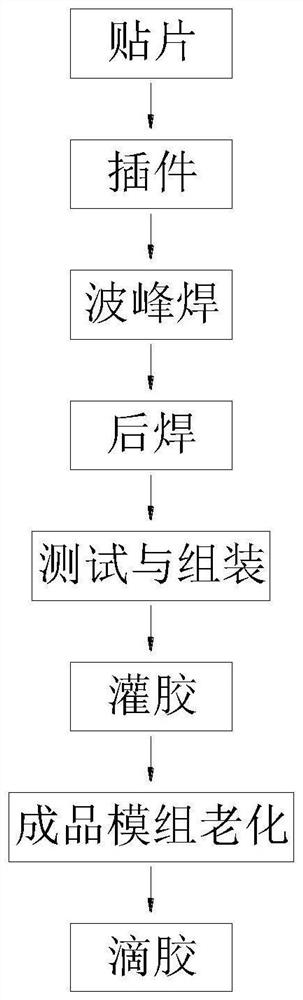

[0022] A kind of production technology of LED display screen that the present invention proposes, comprises the following steps:

[0023] S1, SMD: Fix the electronic components to the PCB panel through the steel mesh. The fixing method is welding. The steel mesh can be red glue steel mesh or solder paste steel mesh. You can use the printing machine to mix the red glue or solder paste evenly. On the PCB panel, the thickness of the red glue is 0.15mm, and the thickness of the solder paste is 0.12-0.15mm. When printing, the steel mesh and the surface of the PCB panel need to be in good contact with each other. The polarity of the pins of the component, the pins of the component are aligned with the pins of the pad, and the soldering temperature of each area on the pad is detected by the temperature detection device during the welding process;

[0024] S2, plug-in: Insert the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com