Trichlorosilane differential pressure coupling rectification process and dynamic control scheme

A technology of trichlorosilane and differential pressure coupling, applied in the direction of distillation adjustment/control, silicon compounds, silicon halide compounds, etc., can solve the problems of unspecified, low difficulty, and many rectification stages, so as to reduce energy consumption , Robust and dynamic control to ensure the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

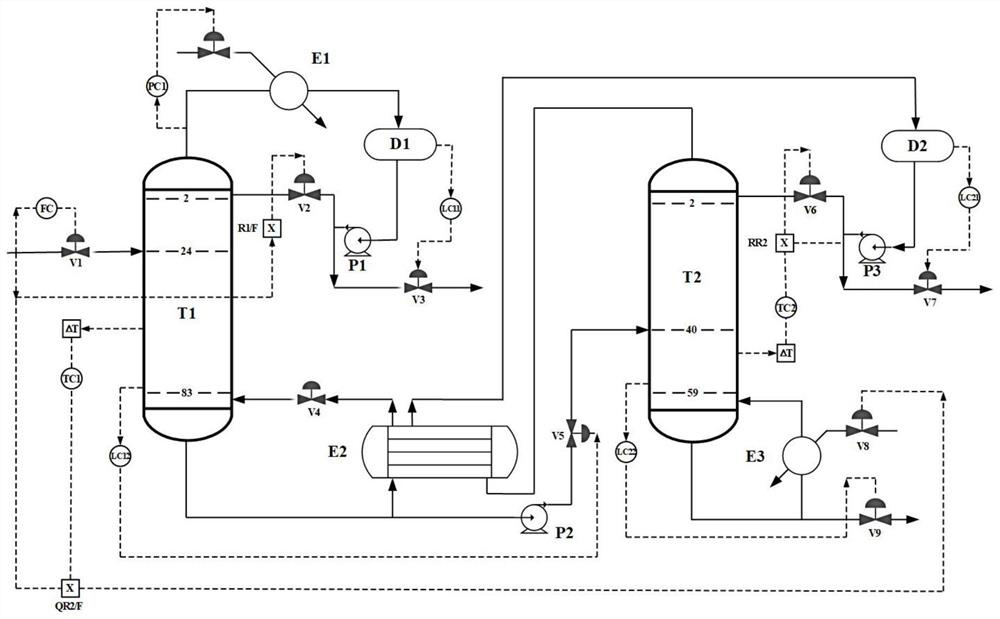

Image

Examples

Embodiment 1

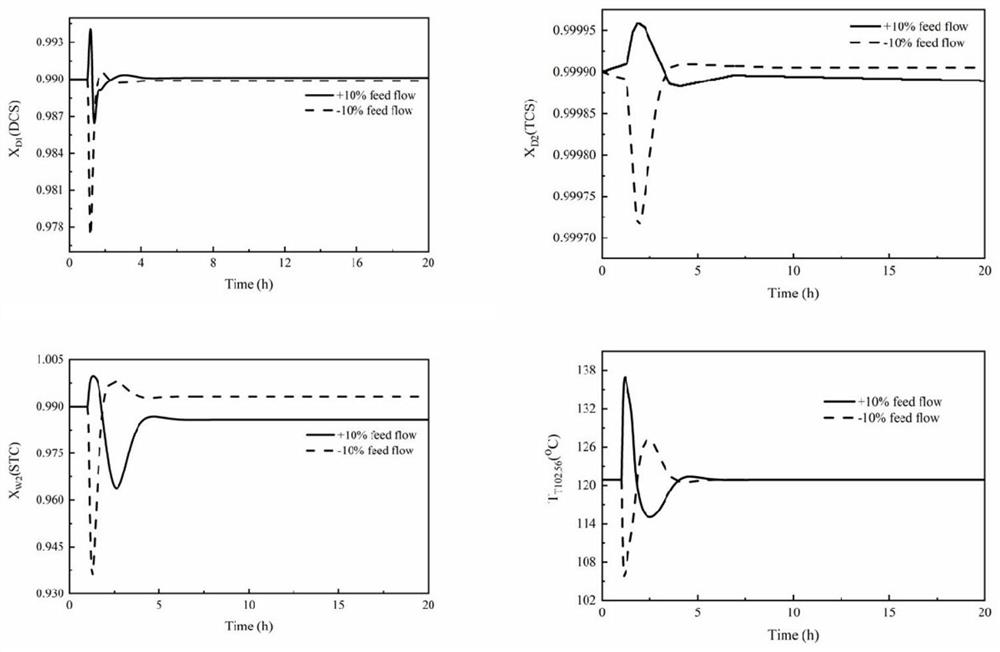

[0041] Each controller first carries out initialization operation, automatically inputs the set value, and reasonably determines the control range, and uses the closed-loop loop as the test method. The feed flow rate is changed from 40000kg / h to 44000kg / h, and the dynamic response curve is as follows figure 2 As shown in (solid line), the overshoot σ of the purity of dichlorodihydrosilane is 0.004, the adjustment time is τ_s is 2h, and the residual e(∞) is 0.0001; the overshoot σ of the purity of trichlorosilane is 0.000058, and the adjustment time τ_s is 4h, residual difference e (∞) is -0.000009; silicon tetrachloride purity overshoot σ is 0.0096, adjustment time is τ_s is 4h, residual difference e (∞) is -0.00427; the temperature of high pressure tower T2 exceeds The adjustment value σ is 16°C, the adjustment time is τ_s is 4h, and the residual e(∞) is 0; it shows that the control process can handle the disturbance of +10% feed flow rate well.

Embodiment 2

[0043] Each controller first carries out initialization operation, automatically inputs the set value, and reasonably determines the control range, and uses the closed-loop loop as the test method. The feed flow rate is changed from 40000kg / h to 36000kg / h, and the dynamic response curve is as follows figure 2Shown in (dotted line), dichlorodihydrosilane purity overshoot σ is-0.0127, the adjustment time is τ_s is 2h, residual difference e (∞) is-0.00012; trichlorosilane purity overshoot σ is-0.00019, The adjustment time is 4h for τ_s, and the residual difference e(∞) is 0.000006; the overshoot of silicon tetrachloride purity σ is -0.0542, the adjustment time is 4h for τ_s, and the residual difference e(∞) is 0.003; the temperature of the high-pressure tower T2 The overshoot σ is -15℃, the adjustment time is τ_s is 4h, and the residual e(∞) is 0; it shows that the control process can handle the disturbance of -10% feed flow rate well.

Embodiment 3

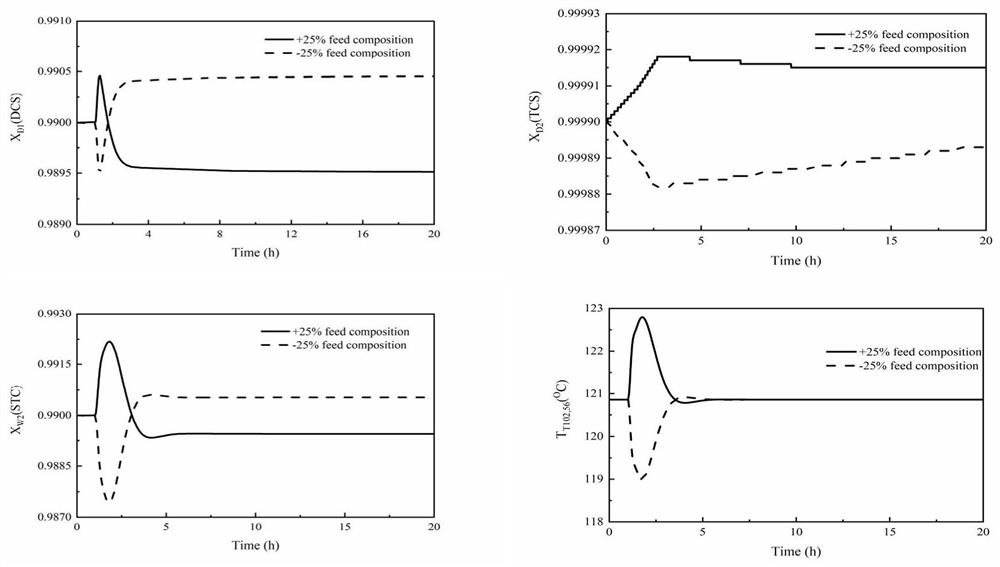

[0045] Each controller first carries out initialization operation, automatically inputs the set value, and reasonably determines the control range, and uses the closed-loop loop as the test method. Feed composition becomes dichlorodihydrosilane 5% by dichlorodihydrosilane 4%, trichlorosilane 92%, silicon tetrachloride 4%, trichlorosilane 90%, silicon tetrachloride 5%, other The dynamic response curve is as image 3 Shown in (solid line), dichlorodihydrosilane purity overshoot σ is 0.00046, the adjustment time is τ_s is 2.5h, residual difference e (∞) is-0.00048; trichlorosilane purity overshoot σ is 0.000018, The adjustment time is 4h for τ_s, and the residual difference e(∞) is 0.000014; the overshoot of silicon tetrachloride purity σ is 0.0021, the adjustment time is 3h for τ_s, and the residual difference e(∞) is -0.00056; the temperature of the high-pressure tower T2 The overshoot σ is 1.9℃, the adjustment time is τ_s is 4h, and the residual e(∞) is 0; it shows that the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com