Glass fiber impregnating compound for enhancing polyvinyl chloride as well as preparation method and application thereof

A technology of glass fiber and polyvinyl chloride, which is applied in the field of glass fiber sizing for reinforced polyvinyl chloride and its preparation, can solve the problems of poor film-forming properties, poor mechanical properties of composite materials, and slow soaking, so as to improve compatibility, Good mechanical properties and the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

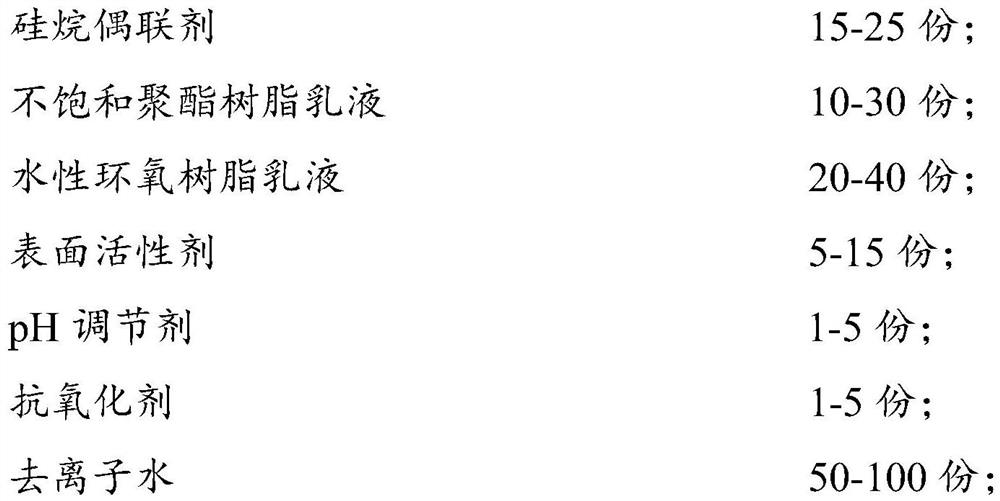

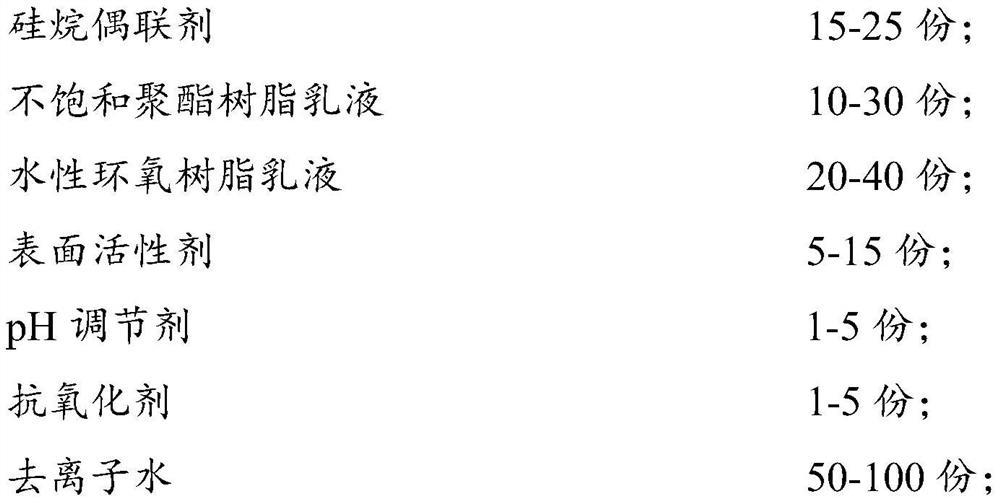

[0030] A preparation method for glass fiber sizing for reinforced polyvinyl chloride, the amount of each substance is shown in the data of Example 1 in Table 1, including:

[0031] Step 1: Dissolve the surfactant in 1 / 2 deionized water, then add the silane coupling agent and mix well;

[0032] Step 2: After diluting the unsaturated polyester resin emulsion and the water-based epoxy resin emulsion with the remaining deionized water respectively, add them to the mixed solution in step 1, and mix well;

[0033] Step 3: Add a pH adjuster and an antioxidant to the solution in Step 2, and mix evenly to obtain a wetting agent.

[0034] The molecular weight of the unsaturated polyester resin emulsion is 800-3000; the molecular weight of the water-based epoxy resin emulsion is 300-500.

[0035] Preferably, the silane coupling agent is a mixture of vinyltriethoxysilane, γ-aminopropyltriethoxysilane and γ-mercaptopropyltriethoxysilane;

[0036] The surfactant is a mixture of fatty alco...

Embodiment 2-6

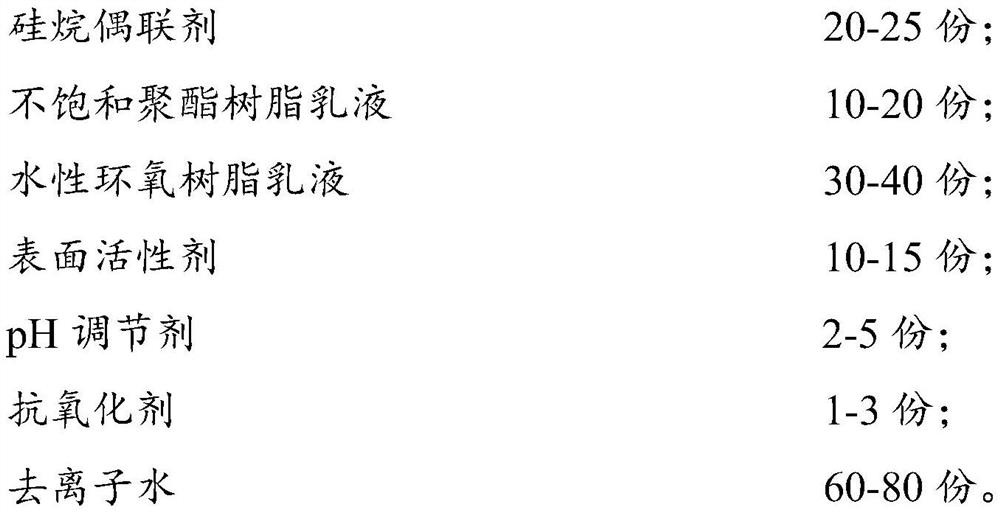

[0039] The contents of each substance are respectively shown as the data in Examples 2-6 in Table 1, and the rest of the conditions are the same as in Example 1.

[0040] In order to further illustrate the beneficial effects of the present application, due to limited space, only Example 3 is used as an example to construct a comparative example as follows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com