Preparation of high-performance low-shrinkage hyperbranched polyamine-ester composite resin for dental restoration

A low-shrinkage dental and hyperbranched polymer technology, which is applied in the field of preparation of dental restoration materials, can solve the problems of reduced strength performance and low shrinkage, and achieve good mechanical properties and excellent mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

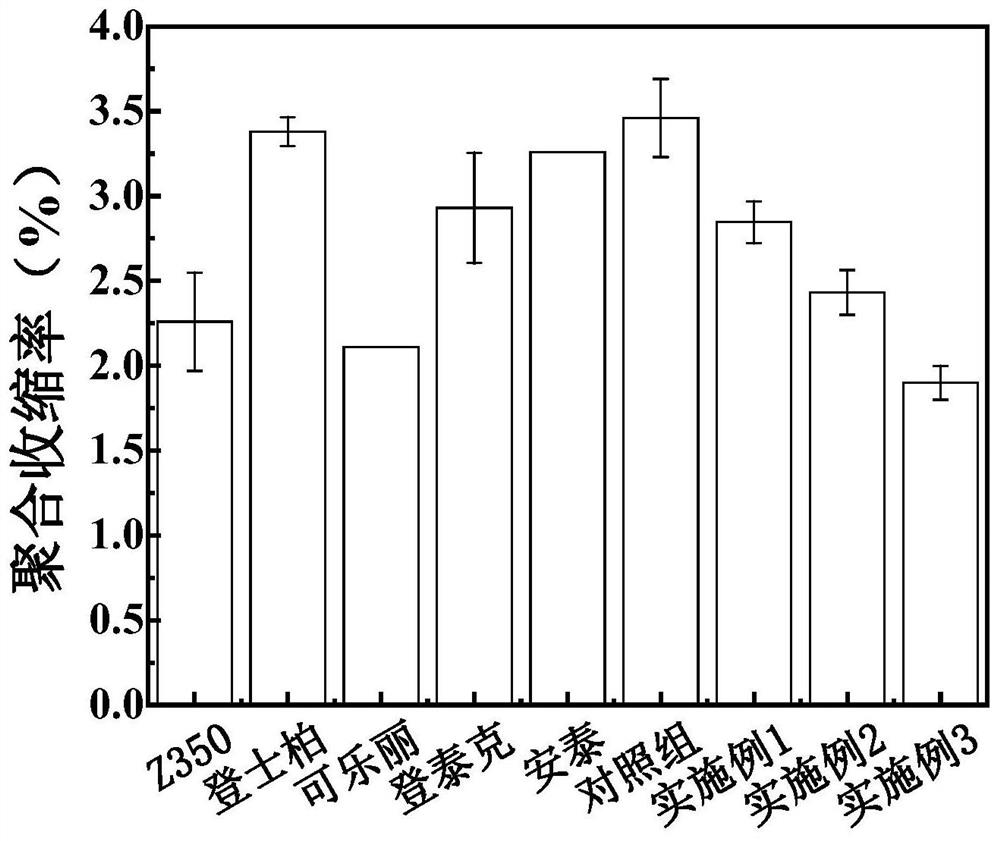

Embodiment 1

[0049] A preparation method of hyperbranched polyamine-ester composite resin for dental restoration with high performance and low shrinkage, the specific process is as follows:

[0050] (1) Preparation of silanized inorganic filler:

[0051] The silanized inorganic filler is prepared by surface modification of the inorganic filler. The specific modification treatment method is: add 50g of the inorganic filler to 600mL of cyclohexane, and the inorganic filler is micron silica (particle size 0.8μm) and nano-silica (particle size 20nm); then stirred and reacted in an oil bath at 20°C for 20min, and then added 5.5mL of n-propylamine and 3.3mL of γ-(methacryloyloxy)propyl Trimethyloxysilane, stirred and reacted at 70°C for 20min. During the reaction, the stirring speed was kept at 800r / min; Dry in a vacuum oven for 24 hours to obtain a silanized inorganic filler.

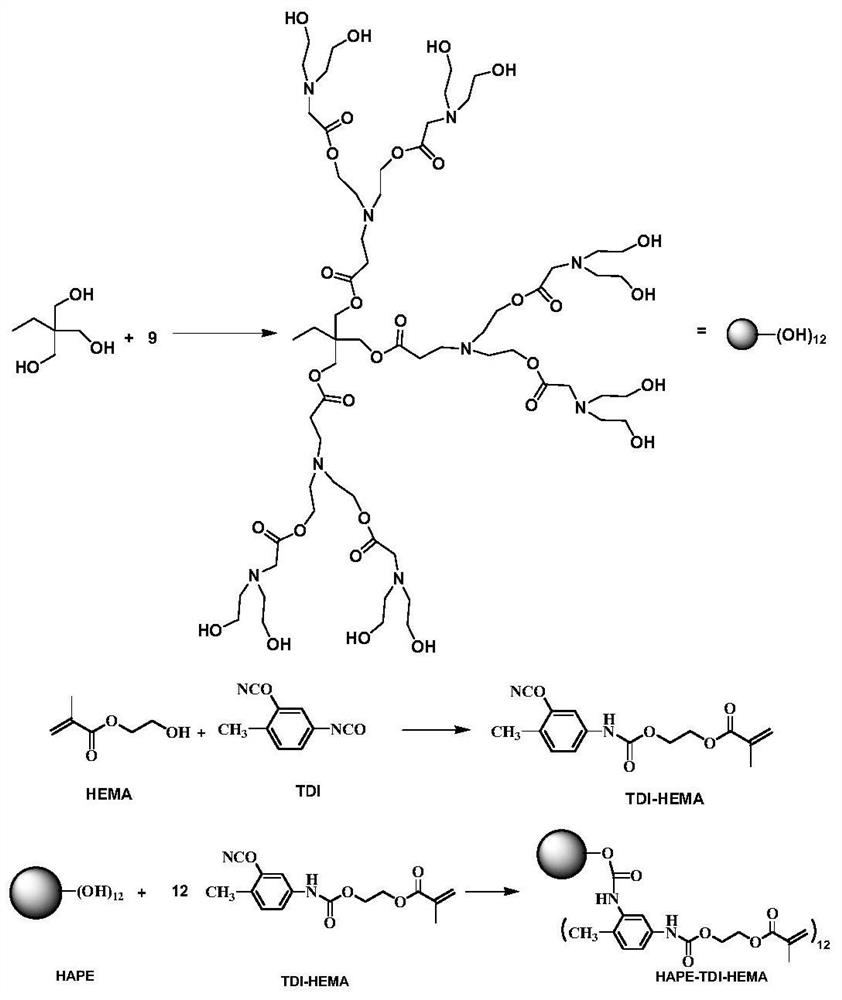

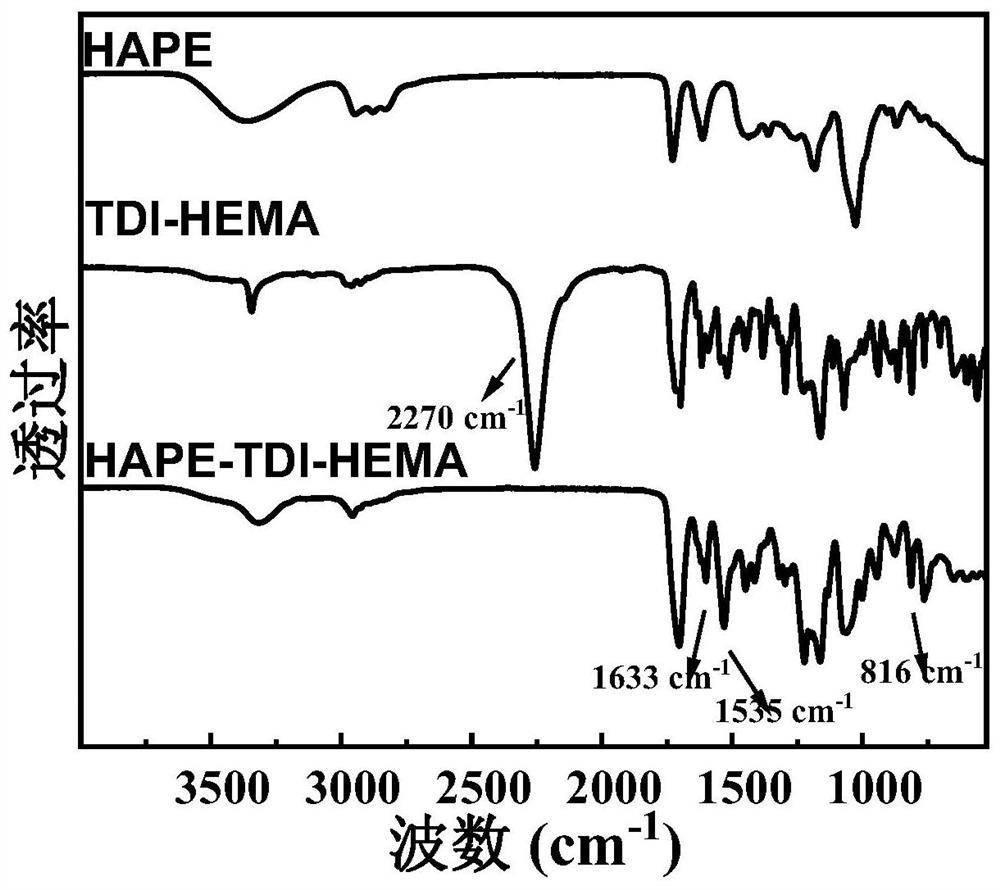

[0052] (2) Preparation of modified hyperbranched polyamine-ester:

[0053] (1) Mix trimethylolpropane, N,N-dihydrox...

Embodiment 2

[0064] A preparation method of hyperbranched polyamine-ester composite resin for dental restoration with high performance and low shrinkage, the specific process is as follows:

[0065] (1) Preparation of silanized inorganic filler:

[0066] The silanized inorganic filler is prepared by surface modification of the inorganic filler. The specific modification treatment method is: add 50g of the inorganic filler to 600mL of cyclohexane, and the inorganic filler is micron silica (particle size 1.2μm) and nano-silica (particle size: 40nm); then stirred and reacted in an oil bath at 30°C for 15min, and then added 5.5mL of n-propylamine and 3.3mL of γ-(methacryloyloxy)propyl Trimethyloxysilane, stirred and reacted at 60°C for 20min. During the reaction, the stirring speed was kept at 700r / min; Dry in a vacuum oven for 24 hours to obtain a silanized inorganic filler.

[0067] (2) Preparation of modified hyperbranched polyamine-ester:

[0068] (1) Mix trimethylolpropane, N,N-dihydro...

Embodiment 3

[0079] A preparation method of hyperbranched polyamine-ester composite resin for dental restoration with high performance and low shrinkage, the specific process is as follows:

[0080] (1) Preparation of silanized inorganic filler:

[0081] The silanized inorganic filler is prepared by surface modification of the inorganic filler. The specific modification treatment method is: add 50g of the inorganic filler to 600mL of cyclohexane, and the inorganic filler is micron silica (particle size 1μm) and nano-silica (particle size: 50nm); then stirred and reacted in an oil bath at 30°C for 10min, then added 5.5mL of n-propylamine and 3.3mL of γ-(methacryloyloxy)propyltri Methyloxysilane, stirred and reacted at 60°C for 30min. During the reaction, the stirring speed was kept at 600r / min; Dry in an oven for 24 hours to obtain a silanized inorganic filler.

[0082] (2) Preparation of modified hyperbranched polyamine-ester:

[0083] (1) Mix trimethylolpropane, N,N-dihydroxyethyl-3-am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com