Preparation and application of a green nanocellulose composite film with high thermal conductivity

A nanocellulose, high thermal conductivity technology, applied in the field of thermally conductive materials, can solve the problems of complicated preparation of thermally conductive materials, harmful to the environment, etc., and achieve the effects of reducing interface thermal resistance and defects, improving thermal conductivity, and reducing agglomeration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

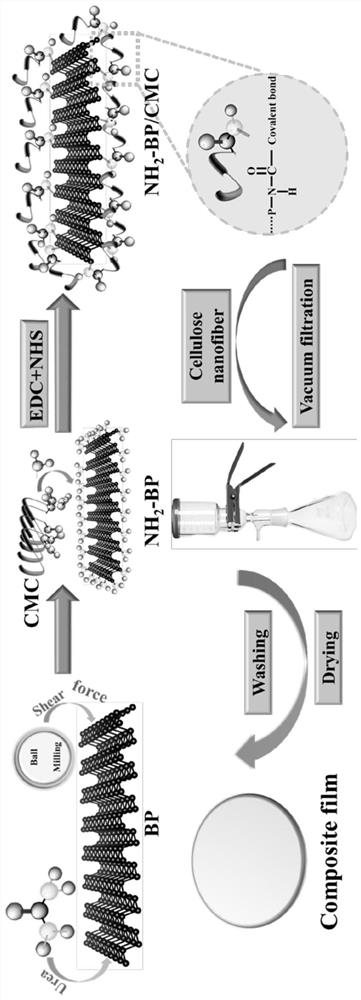

[0037] (1) Take 1.0 g of black phosphorus crystals and 30.0 g of urea, add 125 ml of deionized water, put them in a ball mill and mill them for 4 hours at a speed of 500 r / min. After the ball milling, the reaction solution was centrifuged at 1000 r / min for 10 minutes to remove the bulk phosphorene in the lower layer. Subsequently, the suspension in the upper layer was continuously centrifuged at 5000 r / min for 30 minutes, and the precipitate in the lower layer was placed in a vacuum drying oven at 50° C. for 1 hour to obtain phosphorene amides.

[0038] (2) Take 20.0 mg of carboxymethyl chitosan and add 40 ml of deionized water, stir, and slowly sonicate for 30 minutes, and set the temperature at 35°C. Then transfer to a three-necked flask, add 20 mg of phosphorene amides, adjust the pH between 7-10 with a weak base, add 2.0 mg of 1-ethyl-(3-dimethylaminopropyl) carbodiimide And 3.0mg of N-hydroxysuccinimide, the rotating speed is 300r / min, react for 10 hours, and the obtaine...

Embodiment 2

[0041] (1) Take 1.5g of black phosphorus crystals and 60.0g of urea, add 200ml of deionized water, put them in a ball mill and mill them for 6 hours at a speed of 600r / min. After the ball milling, the reaction solution was centrifuged at 1500 r / min for 15 minutes to remove the bulk phosphorene in the lower layer. Subsequently, the upper suspension was taken and continued to be centrifuged at 6000 r / min for 35 minutes, and the lower sediment was taken and placed in a vacuum drying oven at 60° C. for 1 hour to obtain phosphorene amides.

[0042] (2) Take 25.0 mg of carboxymethyl chitosan and add 50 ml of deionized water, stir, and slowly sonicate for 60 minutes, and set the temperature at 38°C. Then transfer to a three-necked flask, add 25 mg of phosphorene amides, adjust the pH between 7-10 with a weak base, add 2.5 mg of 1-ethyl-(3-dimethylaminopropyl) carbodiimide And 4.0mg of N-hydroxysuccinimide, the rotating speed is 350r / min, react for 5 hours, and the obtained product i...

Embodiment 3

[0045] (1) Take 2.0g of black phosphorus crystals and 80.0g of urea, add 250ml of deionized water, put them in a ball mill and mill them for 8 hours at a speed of 650r / min. After the ball milling, the reaction solution was centrifuged at 2000 r / min for 20 minutes to remove the bulk phosphorene in the lower layer. Subsequently, the upper suspension was taken and continued to be centrifuged at 6500 r / min for 40 minutes, and the lower sediment was placed in a vacuum drying oven at 70° C. for 2 hours to obtain phosphorene amides.

[0046] (2) Take 30.0 mg of carboxymethyl chitosan and add 60 ml of deionized water, stir, and slowly sonicate for 50 minutes, and set the temperature at 40°C. Then transfer to a three-necked flask, add 30 mg of phosphorene amides, adjust the pH between 7-10 with a weak base, add 5.0 mg of 1-ethyl-(3-dimethylaminopropyl) carbodiimide And 6.0mg of N-hydroxysuccinimide, the rotating speed is 300r / min, react for 6 hours, and the obtained product is aminoph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com