Super-hydrophobic surface modification method based on photothermal effect, and surface super-hydrophobized material and application thereof

A technology of superhydrophobic surface and photothermal effect, applied in nanotechnology, special surface, pretreated surface, etc. for materials and surface science, it can solve problems such as equipment size limitation and equipment cost increase, and achieve high service life and equipment. Low cost and universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

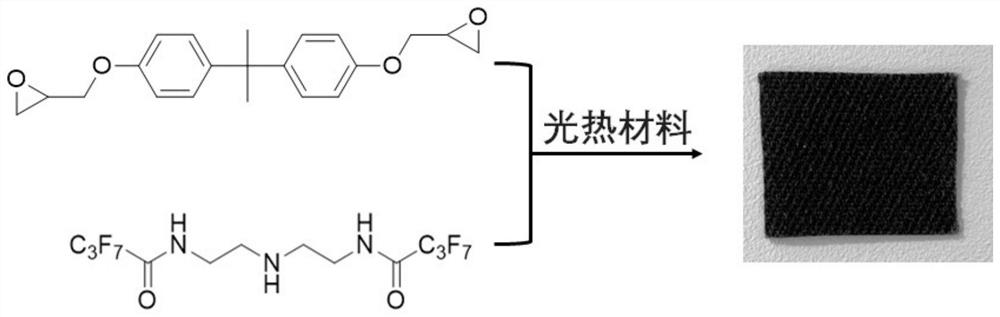

[0035] A superhydrophobic surface modification method based on photothermal effect, comprising the following steps:

[0036] Step 1. Perform surface pretreatment on the selected base material. A glass sheet with a size of 30mm×40mm was placed in a concentration of 0.1M for ultrasonic treatment for 30min, rinsed with deionized water, dried, and then cleaned with PLASMA plasma surface treatment equipment for a second time.

[0037] Step 2, fluorinating the epoxy resin curing agent diethylenetriamine. Put 10mL of deionized aqueous solution of diethylenetriamine with a concentration of 0.1g / mL and 10mL of deionized aqueous solution of heptafluorobutyric acid with a concentration of 0.2g / mL in a round-bottomed flask, stir well and set the oil bath reaction The temperature is 100°C, and the reaction time is 6 hours to obtain the reaction product, fluorinated diethylenetriamine, which is ready for use;

[0038] Step 3, adding photothermal materials into the epoxy resin. Take 2.0g ...

Embodiment 2

[0042] A superhydrophobic surface modification method based on photothermal effect, comprising the following steps:

[0043]Step 1, perform surface pretreatment on the selected base material. A glass sheet with a size of 30mm×40mm was placed in a concentration of 0.1M for ultrasonic treatment for 30min, rinsed with deionized water, dried, and then cleaned with PLASMA plasma surface treatment equipment for a second time.

[0044] Step 2, fluorinating the epoxy resin curing agent diethylenetriamine. Put 10mL of deionized aqueous solution of diethylenetriamine with a concentration of 0.1g / mL and 10mL of deionized aqueous solution of heptafluorobutyric acid with a concentration of 0.2g / mL in a round-bottomed flask, stir well and set the oil bath reaction The temperature is 100°C, and the reaction time is 6 hours to obtain the reaction product, fluorinated diethylenetriamine, which is ready for use;

[0045] Step 3, adding photothermal materials into the epoxy resin. Take 2.0g o...

Embodiment 3

[0049] A superhydrophobic surface modification method based on photothermal effect, comprising the following steps:

[0050] Step 1. Perform surface pretreatment on the selected base material. Clean and pretreat the surface of the titanium sheet with a size of 100mm×100mm using PLASMA plasma surface treatment equipment, and then partition the titanium sheet with a size of 30mm×40mm by 3M tape.

[0051] Step 2, fluorinating the epoxy resin curing agent diethylenetriamine. Put 10mL of deionized aqueous solution of diethylenetriamine with a concentration of 0.1g / mL and 10mL of deionized aqueous solution of heptafluorobutyric acid with a concentration of 0.2g / mL in a round-bottomed flask, stir well and set the oil bath reaction The temperature is 100°C, and the reaction time is 6 hours to obtain the reaction product, fluorinated diethylenetriamine, which is ready for use;

[0052] Step 3, adding photothermal materials into the epoxy resin. Take 2.0g of bisphenol A-based epoxy r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com