Method for detecting gas production rate of aerogenic bacteria in fermented bean curd

A technology of gas production and gas producing bacteria, applied in the field of food processing, can solve the problems of loss of enterprises, high requirements for gas production control of fermented bean curd, inconvenience of carrying glass bottles, and inconvenience in eating, etc., and achieves the effect of ensuring product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

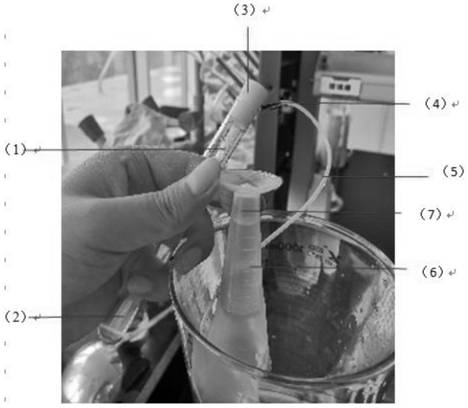

[0091] (1) Sample treatment: 20 g of fermented bean curd samples to be tested with different degrees of bulging and gas production were mashed with a sterilized spoon into a paste, and then the samples were added to a container containing 100 ml of sterilized normal saline and glass beads. In the Erlenmeyer flask, fully disperse in a vortex shaker for 5 minutes until uniform. Prepare a uniform dilution of fermented bean curd, the concentration of the dilution is 1:5;

[0092] (2) Culture medium preparation and subpackaging: 800ml of fermented bean curd broth filtered through 8 layers of gauze after fermentation for 4 months (0.6mg / 100ml of amino acid nitrogen content), 3g of peptone, 5g of glucose, and 200ml of distilled water. After the above-mentioned medium components were dissolved, they were divided into two 1000ml Erlenmeyer flasks, sealed with sterile sealing film, sterilized at 121°C for 30min, and cooled at room temperature. The sterilized and cooled culture medium i...

Embodiment 2

[0099] (1) Sample treatment: 25g of fermented bean curd samples to be tested with different degrees of bulging and gas production were mashed with a sterilized spoon into a paste, and then the samples were added to a container containing 200ml of sterilized normal saline and glass beads. In the Erlenmeyer flask, fully disperse in a vortex shaker for 5 minutes until uniform. Prepare a uniform dilution of fermented bean curd, the concentration of the dilution is 1:8

[0100] (2) Culture medium preparation and subpackaging: 600ml of fermented bean curd broth filtered through 8 layers of gauze after 5 months of fermentation (0.8mg / 100ml of amino acid nitrogen content), 4g of peptone, 8g of glucose, and 400ml of distilled water. After the above-mentioned medium components were dissolved, they were divided into two 1000ml Erlenmeyer flasks, sealed with sterile sealing film, sterilized at 121°C for 20min, and cooled at room temperature. The sterilized and cooled culture medium is di...

Embodiment 3

[0107](1) Sample processing: In the aseptic operating table, 20g of finished fermented bean curd samples to be tested in different batches are mashed into a paste with a sterilized spoon, and then the samples are added to a triangular flask filled with 100ml sterilized normal saline and glass beads In the vortex shaker, fully disperse for 5 minutes until uniform. Prepare a uniform dilution of fermented bean curd, the concentration of the dilution is 1:5

[0108] (2) Culture medium preparation and subpackaging: 800ml of fermented bean curd broth filtered through 8 layers of gauze after fermentation for 4 months (0.6mg / 100ml of amino acid nitrogen content), 3g of peptone, 5g of glucose, and 200ml of distilled water. After the above-mentioned medium components were dissolved, they were divided into two 1000ml Erlenmeyer flasks, sealed with sterile sealing film, sterilized at 121°C for 30min, and cooled at room temperature. The sterilized and cooled culture medium is divided into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com