Calibration method of thin film thermal resistance heat flow meter and coaxial thermocouple for heat flow test

A calibration method and thermal resistance technology, applied in thermometer testing/calibration, thermometers, calorimeters, etc., can solve problems such as inaccurate heat flow results, achieve reliable test result uncertainty evaluation results, and clarify the need for traceability of quantities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

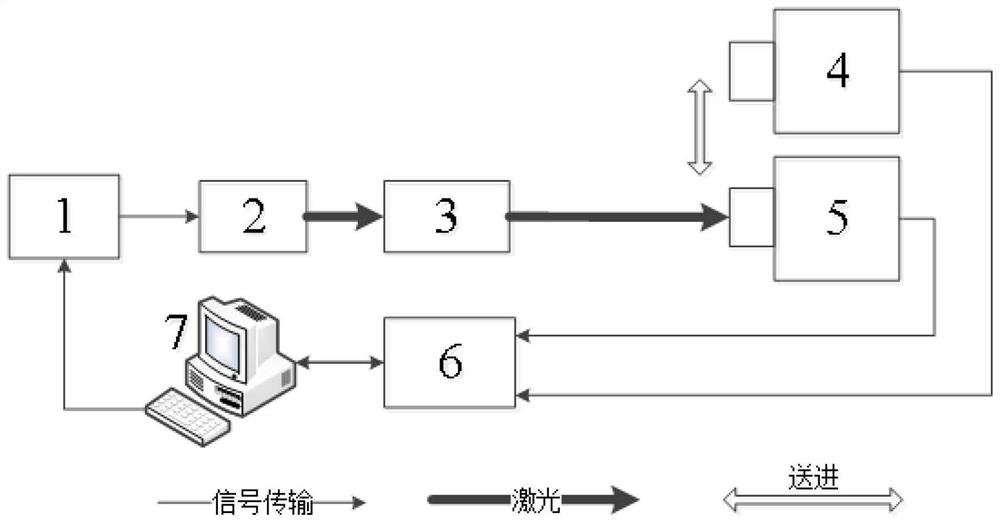

Method used

Image

Examples

Embodiment 1

[0048] To calibrate a thin film thermal resistance heat flow meter, the calibration steps include:

[0049] Step 1. Check the heat flow sensor calibration equipment, determine the calibration heat flow range, and select 5 different calibration heat flow points, and use the atomic layer thermopile heat flow sensor to check the stability of the calibration heat flow in time;

[0050] Step 2. Spray a layer of carbon black coating on the surface of the thin film thermal resistance heat flow meter to be calibrated, the coating thickness is not more than 1 μm; the coating material can also be one of colloidal graphite, gold black or platinum black; The base material of the resistance heat flow meter is polyimide, and polyether ether ketone can also be used; when the base material of the thin film heat resistance heat flow meter is glass or ceramics, a layer of diamond film should be deposited on the sensing surface of the thin film heat resistance heat flow meter, thus Other coating...

Embodiment 2

[0066] To calibrate a coaxial thermocouple, the calibration steps include:

[0067] Step 1. Check the heat flow sensor calibration equipment, determine the calibration heat flow range, and select 5 different calibration heat flow points, and use the atomic layer thermopile heat flow sensor to check the stability of the calibration heat flow in time;

[0068] Step 2. Spray a layer of carbon black coating on the surface of the coaxial thermocouple to be calibrated. The coating can also be one of gold black, colloidal graphite or platinum black coating, and the coating thickness does not exceed 1 μm;

[0069] Step 3. Fix the coaxial thermocouple to be calibrated at the designated position of the heat flow sensor calibration equipment;

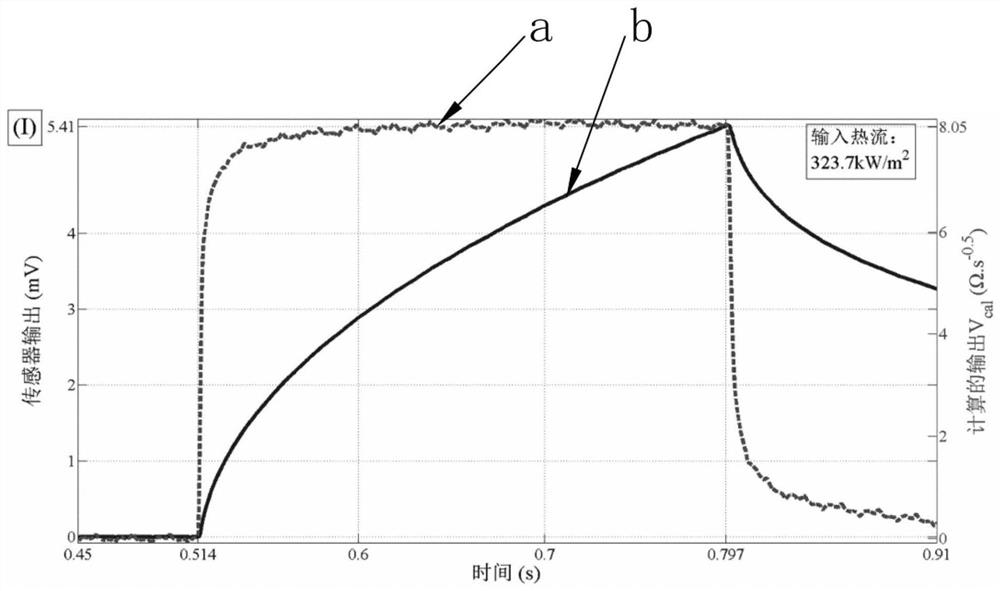

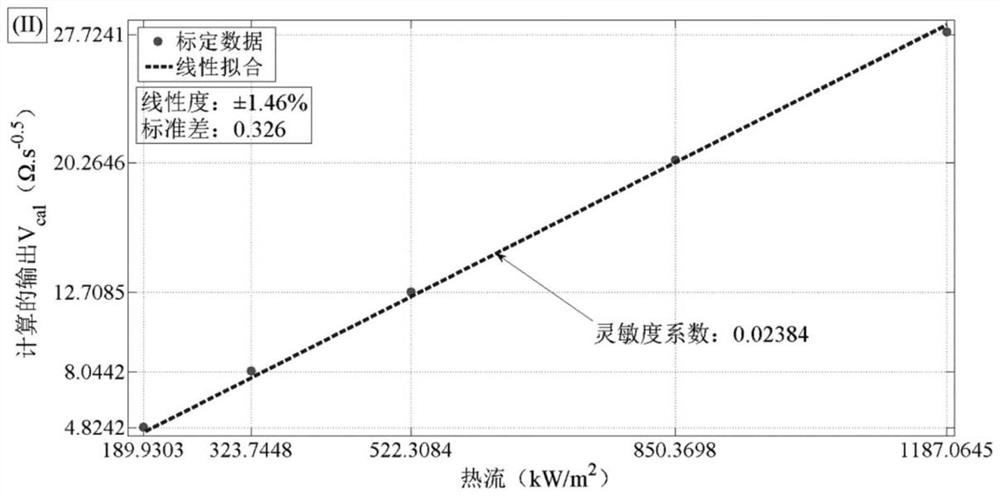

[0070] Step 4, set the parameters of the function generator and the dynamic data acquisition instrument, turn on the fiber laser and the dynamic data acquisition instrument, and obtain the output of the coaxial thermocouple under a certain calibra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| gauge factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com