Separation and purification method of macromolecular depside in tree moss extract

A technology of molecular depacid and tree moss extract is applied in the field of separation and purification of macromolecular depacids in tree moss extract. , expand the application field, and easily add effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

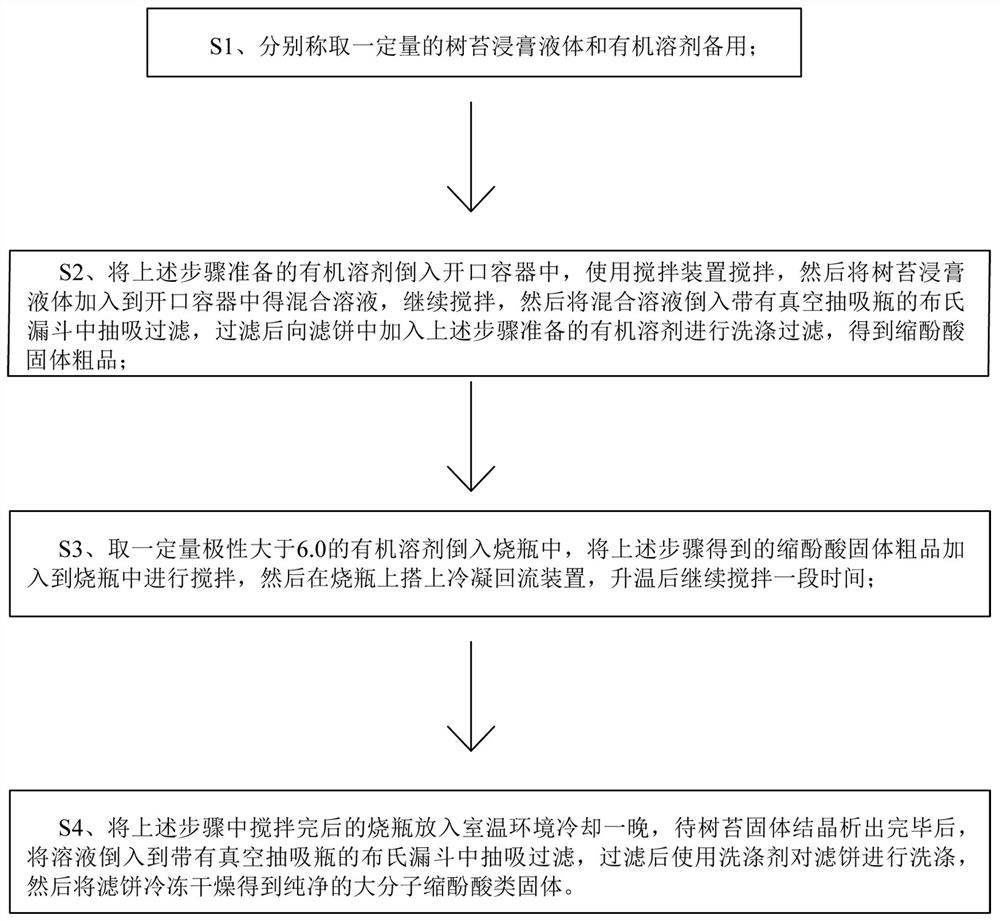

Method used

Image

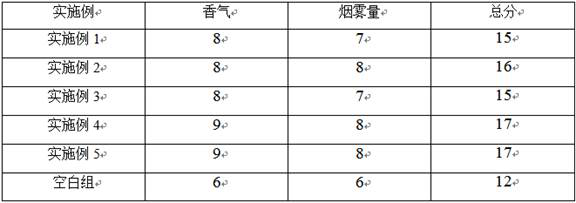

Examples

Embodiment 1

[0031] S1. Weigh 20g of acetonitrile solvent and pour it into a large beaker, stir with a magnetic stirrer at a stirring speed of 400r / min, weigh 2g of tree moss extract liquid in a small beaker, and then use a dropper to remove the tree moss extract liquid in the small beaker. Add the liquid moss extract dropwise into a large beaker to obtain a mixed solution. After the addition, continue to stir for 40 minutes, then pour the mixed solution into a Buchner funnel with a vacuum suction bottle for suction and filtration, and control its vacuum degree to 5kPa After filtering, add acetonitrile solvent to the filter cake to wash and filter to obtain 0.91 g of brown depsipolic acid solid crude product;

[0032] S2. Pour 30mL of ethylene glycol solvent into a round-bottomed flask, add 0.91g of brown depsipphenolic acid solid crude product into the round-bottomed flask for stirring, then put a condensation reflux device on the flask, heat up to 120°C, and stir for 20 min;

[0033] S3...

Embodiment 2

[0035]S1. Weigh 40g of dimethylformamide solvent and pour it into a large beaker, stir with a magnetic stirrer at a stirring speed of 600 r / min, weigh 3g of tree moss extract liquid in a small beaker, and then use a dropper to The tree moss extract liquid was added dropwise in a large beaker to obtain a mixed solution. After the addition was completed, continue to stir for 30 minutes, then pour the mixed solution into a Buchner funnel with a vacuum bottle for suction and filtration, and control its vacuum degree to be 10kPa, after filtering, add dimethylformamide solvent to filter cake and wash and filter, obtain 1.35 g brown depsipphenolic acid solid crude product;

[0036] S2. Pour 30 mL of acetic acid solvent into a round-bottomed flask, add 1.35 g of brown depsipphenolic acid solid crude product into the round-bottomed flask for stirring, then put a condensation reflux device on the flask, heat up to 100 °C, and stir for 30 min;

[0037] S3, after the brown phenolic acid s...

Embodiment 3

[0039] S1. Weigh 60g of dimethyl sulfoxide solvent and pour it into a large beaker, stir with a magnetic stirrer at a stirring speed of 800 r / min, weigh 2g of tree moss extract liquid in a small beaker, and then use a dropper to The tree moss extract liquid was added dropwise in a large beaker to obtain a mixed solution. After the addition was completed, continue to stir for 20 minutes, then pour the mixed solution into a Buchner funnel with a vacuum bottle for suction and filtration, and control its vacuum degree to be 20kPa, after filtering, add dimethyl sulfoxide solvent to filter cake and wash and filter, obtain 0.92 g brown depsipphenolic acid solid crude product;

[0040] S2. Pour 30 mL of dimethylformamide solvent into a round-bottomed flask, add 0.92 g of brown depsipphenolic acid solid crude product into the round-bottomed flask for stirring, then put a condensation reflux device on the flask, and heat up to 80°C. Stir for 40 min;

[0041] S3. After the brown phenoli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com