Sitafloxacin tablet and preparation method thereof

A sitafloxacin and tablet technology, applied in the pharmaceutical field, can solve the problems of cumbersome preparation process, low dissolution rate of active ingredients in tablets, and it takes more than 2 hours to achieve good without interference, and achieves good dissolution rate. , The effect of reducing the time of crystallization and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

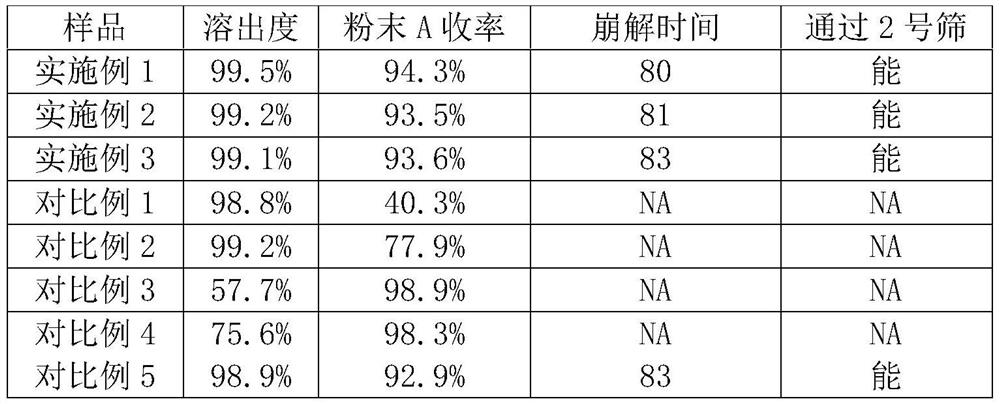

Examples

preparation example Construction

[0025] The present invention provides a kind of preparation method of sitafloxacin tablet, it is characterized in that, comprises the steps:

[0026] S1 Add 30-40g of sitafloxacin crude product into 500ml of water, add it into 0.1mol / L sodium hydroxide solution at a constant speed and stir until the precipitate is completely dissolved;

[0027] S2 decolorizes and filters the solution with activated carbon to remove physical impurities, and collects the filtrate;

[0028] S3 Add a mixture of 100ml ethanol and 100-400ml acetone to the filtrate and stir to remove the organic phase, then add 0.1mol / L hydrochloric acid solution to adjust the pH to 6.5-7, stir and crystallize for 45 minutes, add 0.5- 1g of iron oxide powder; the method of adding iron oxide powder is to add in three equal amounts, and the adding time points are 0, 15, and 30 minutes respectively.

[0029] S4 collects the precipitate by filtration and rinses the precipitate with ethanol, and obtains powder A after dr...

Embodiment 1

[0034] Preparation:

[0035] S1 Add 30g of sitafloxacin crude product into 500ml of water, add it into 0.1mol / L sodium hydroxide solution at a constant speed and stir until the precipitate is completely dissolved;

[0036] S2 decolorizes and filters the solution with activated carbon to remove physical impurities, and collects the filtrate;

[0037] S3 adds the mixed solution that 100ml ethanol and 350ml acetone forms in the filtrate and removes the organic phase after stirring, then adds 0.1mol / L hydrochloric acid solution to adjust pH7, stirs and crystallizes for 45 minutes, adds 0.8g iron oxide powder in the stirring process; Iron oxide The method of adding the powder is to add in three equal amounts, and the adding time points are respectively 0, 15, and 30 minutes.

[0038] S4 collects the precipitate by filtration and rinses the precipitate with ethanol, and obtains powder A after drying;

[0039] S5 Add mannitol into the grinder and add powder A step by step in equal ...

Embodiment 2

[0042] Preparation:

[0043] S1 Add 40 g of sitafloxacin crude product into 500 ml of water, add it into 0.1 mol / L sodium hydroxide solution at a constant speed and stir until the precipitate is completely dissolved;

[0044] S2 decolorizes and filters the solution with activated carbon to remove physical impurities, and collects the filtrate;

[0045] S3 Add a mixed solution of 100ml ethanol and 100ml acetone to the filtrate and stir to remove the organic phase, then add 0.1mol / L hydrochloric acid solution to adjust pH6.5, stir and crystallize for 45 minutes, add 1g iron oxide powder during stirring; The method of adding the iron powder is to add in three equal amounts, and the adding time points are 0, 15, and 30 minutes respectively.

[0046] S4 collects the precipitate by filtration and rinses the precipitate with ethanol, and obtains powder A after drying;

[0047] S5 Add mannitol into the grinder and add powder A step by step in equal amounts for co-grinding until the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com