A multi-source and multi-stream electric locomotive traction drive system topology

An electric locomotive and traction drive technology, applied in the traction of AC induction motors, electric vehicles, power management and other directions, can solve the problems of low transportation efficiency, single energy transmission mode, reduced size and weight, etc., to reduce the number of equipment and save Cost, effect of reducing size and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

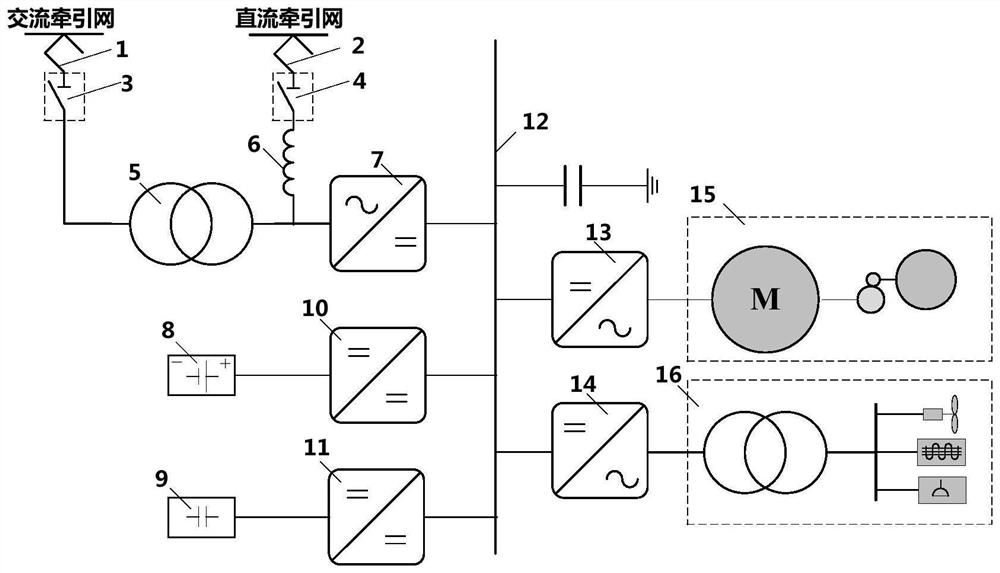

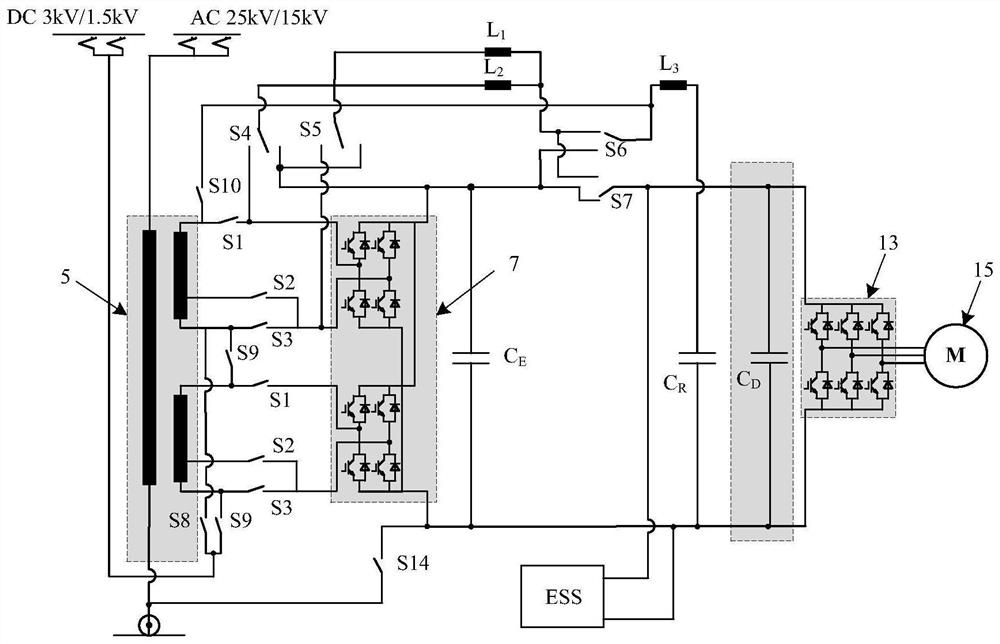

[0040] This embodiment provides a multi-source and multi-stream electric locomotive traction drive system topology based on on-board hybrid energy storage, such as figure 1 shown, including: AC pantograph (1), DC pantograph (2), AC main circuit breaker (3), DC main circuit breaker (4), traction transformer (5), DC smoothing reactor (6) ), grid-side rectifier (7), power battery (8), super capacitor (9), power battery energy storage converter (10), super capacitor energy storage converter (11), DC link (12) , a traction inverter (13), an auxiliary converter (14), a traction motor system (15), auxiliary equipment (16) and several switch units.

[0041] The first end of the AC pantograph (1) is connected to the AC traction power supply catenary, and the second end is connected to the high-voltage side end of the traction transformer (5) through the AC main circuit breaker (3). The other end of the high-voltage side is connected to the wheel and rail; the low-voltage side of the t...

Embodiment 2

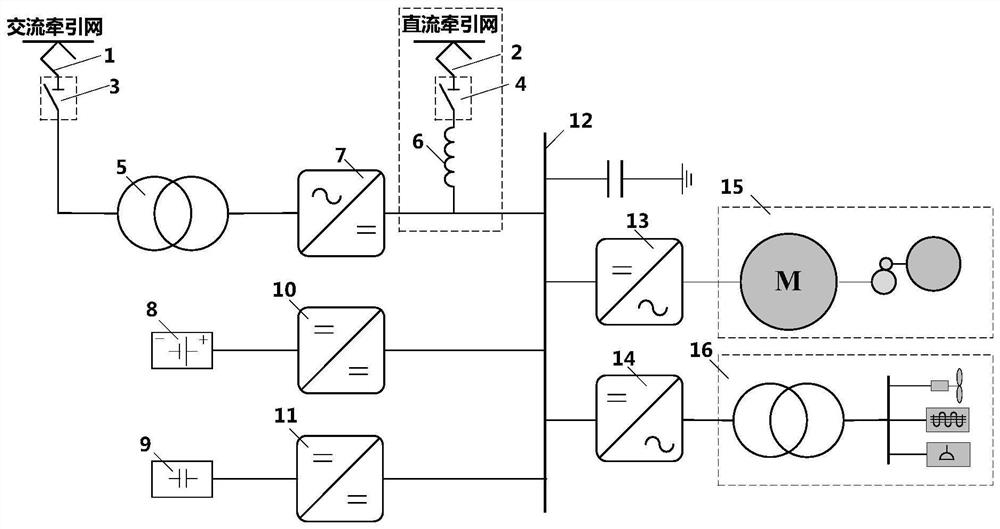

[0082] The topology of the multi-source multi-stream electric locomotive traction drive system based on on-board hybrid energy storage provided by this embodiment, such as image 3 , Figure 4 As shown, the difference from Embodiment 1 is that the second end of the DC smoothing reactor (6) does not need to use the multiplexed grid-side transformer as a DC / DC chopper through switches S4, S5, S6, and S7 before outputting To the DC link, but directly output to the DC link (12) by closing the switch S12.

[0083] In this embodiment 2, the secondary filter branch includes a fourth inductor L4, a fifth inductor L5, and a capacitor C connected in series in sequence R '; A switch S13 is connected in parallel at both ends of the fourth inductor L4. If powered by the DC traction power supply contact line, the switch S12 is closed; if the AC traction power supply contact line is powered, the switch S12 is open, and the switch S13 determines the switch state according to the frequency o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com