Self-sensing intelligent conductive asphalt pavement material

A technology of conductive asphalt and pavement materials, which is applied in the field of self-sensing intelligent conductive asphalt pavement materials, and can solve problems such as the complex stress mode of internal particles in the law of stress transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

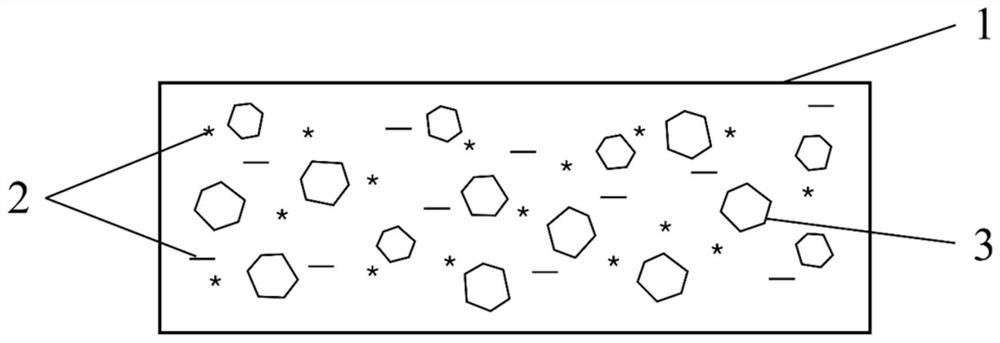

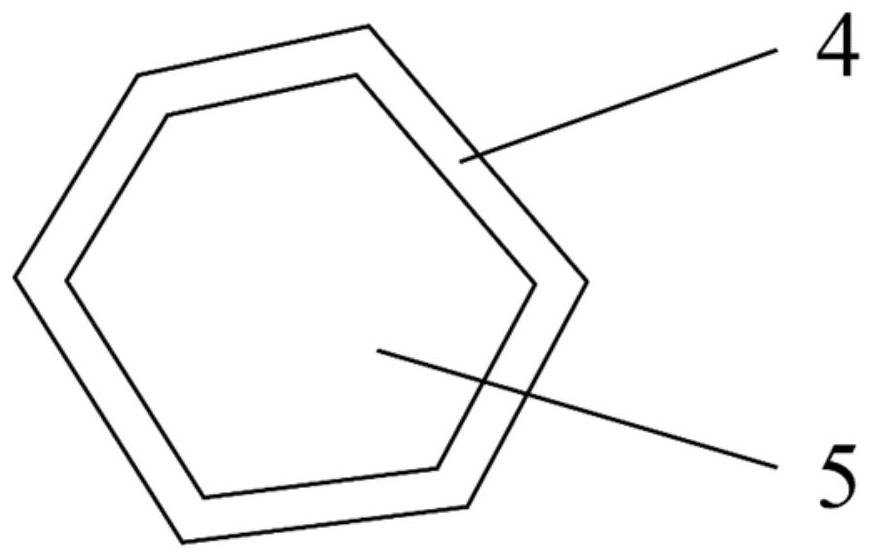

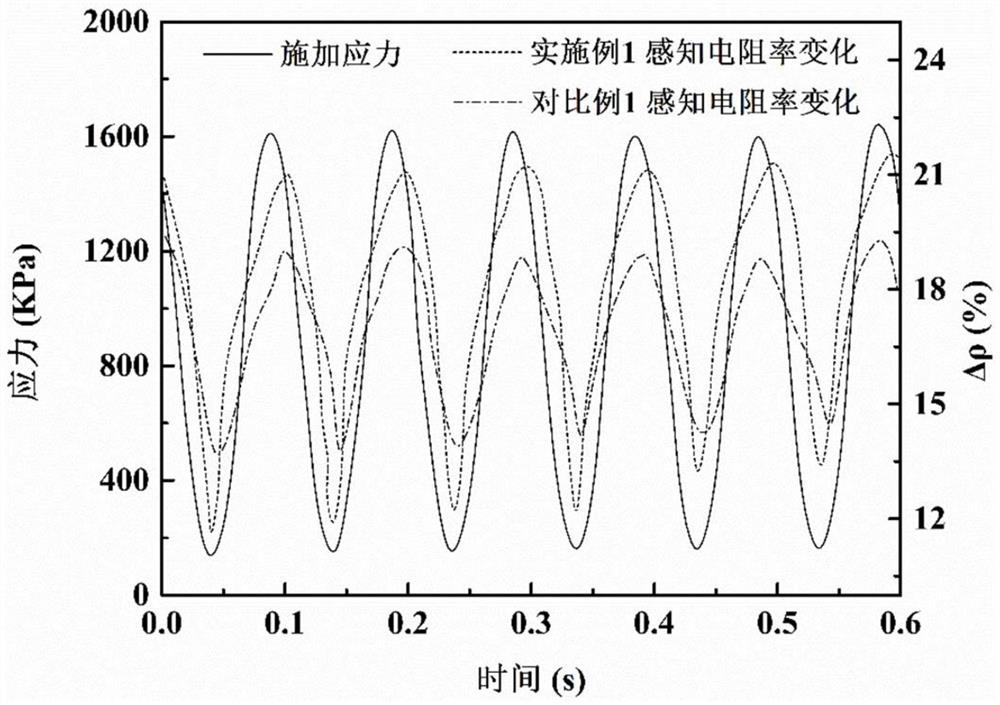

[0029] like figure 1 The shown self-sensing intelligent conductive asphalt pavement material includes an asphalt mixture 1 and a first conductive material 2 distributed in the asphalt mixture 1 and added in an amount of 0.3 wt%. The asphalt mixture 1 adopts AC-13 gradation, the No. 70 A grade road petroleum asphalt content is 4.9wt%, the asphalt softening point is 47.5°C, and the penetration is 67 (0.1mm); the first conductive material 2 is carbon nanofiber. The surface of the coarse aggregate 5 in the asphalt mixture 1 is also covered with a conductive cement-based coating 4, and forms a smart aggregate unit 3, such as figure 2 shown. The thickness of the conductive cement-based coating 4 is ~2mm, and it is obtained by coagulation and hardening of commercially available P.O.42.5 ordinary Portland cement slurry (ie, cementitious material) mixed with a second conductive material; wherein, the water-cement ratio of the slurry is 0.35; The second conductive material is multi-l...

Embodiment 2

[0033] A self-sensing intelligent conductive asphalt pavement material of this embodiment is prepared by adding 0.5wt% of the first conductive material 2 to the asphalt mixture 1; wherein the first conductive material 2 is nano-carbon fiber, and the addition amount is 0.5wt%; used Asphalt mixture 1 adopts SMA-13 gradation, in which the content of SBS modified asphalt is 5.6wt%, the softening point of SBS modified asphalt (Type I-D) is 72.0°C, and the penetration is 54 (0.1mm). The conductive cement-based coating 4 in the intelligent aggregate unit 3 has a thickness of ~1 mm, and is obtained by coagulating and hardening the commercially available P.O.52.5 ordinary Portland cement slurry (ie, cementitious material) mixed with a second conductive material; wherein, the slurry The volume water-cement ratio is 0.35; the second conductive material is carbon nanofiber, and the dosage is 2.0wt%.

[0034] According to the above technical requirements, the asphalt mixture 1 specimen w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com