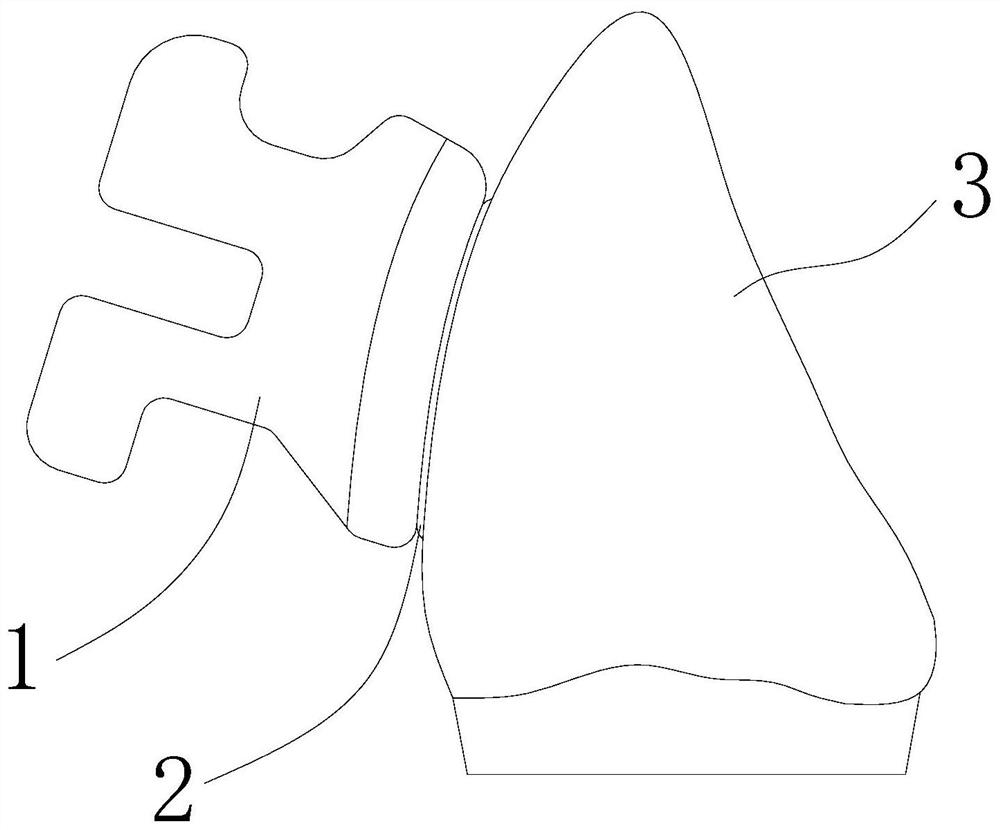

Preparation method of orthodontic zirconia bracket

A technology of zirconia and zirconia ceramics, which is applied in brackets, orthodontics, orthodontics, etc., can solve the problems of inability to cover, high manufacturing difficulty, and high cost of mold opening, so as to improve the weak bonding and simplify production Process, reduce the effect of mold opening costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

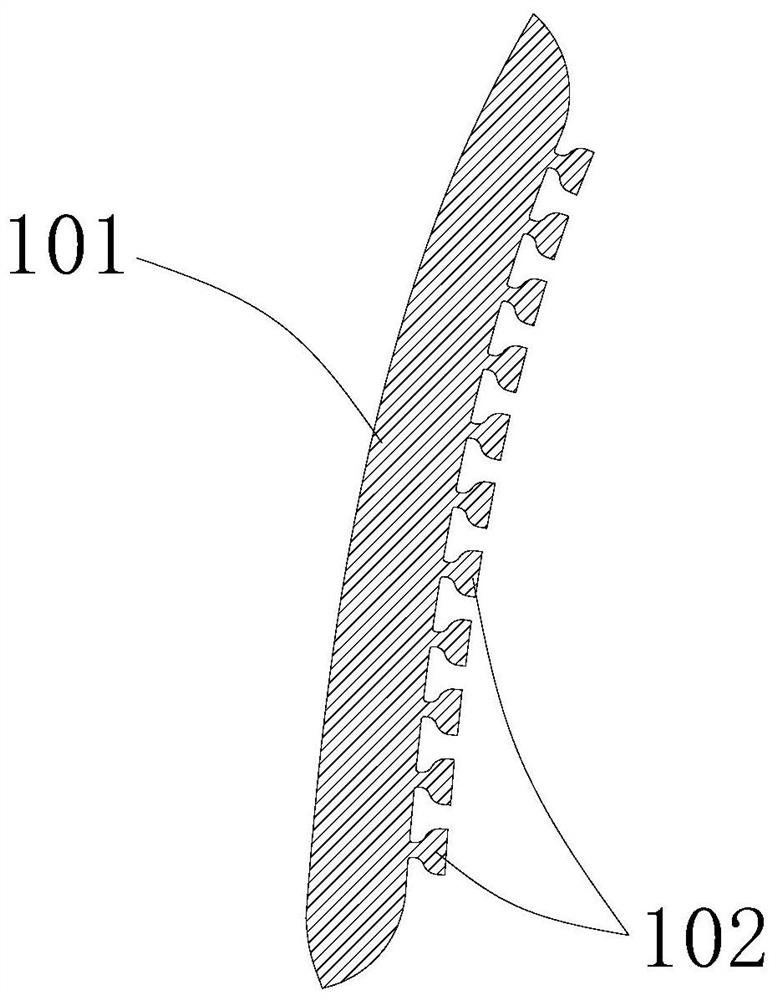

[0031] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0032] A kind of preparation method of orthodontic zirconia bracket of the present embodiment comprises the following steps:

[0033] (1) Prepare zirconia ink slurry with a solid phase content of 30%-60% as a raw material. This ceramic slurry is composed of nano-zirconia particles, auxiliary solvent (mainly glycol ether mixture), binder (a mixture of lipid and hydrocarbon organic matter), and has good biocompatibility and high bending strength. The support slurry is composed of nano-sodium carbonate particles, auxiliary solvent, and dispersant, and can be quickly dissolved in soft water at 20-40°C.

[0034] (2) The doctor clinically uses an intraoral three-dimensional scanner (CT scan or non-contact scanner) to obtain the patient's dentition data, that is, the tooth surface shape information of the pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com