Lead manganate niobate-lead nickelate niobate-lead zirconate titanate high-voltage ferroelectric ceramic with ultralow dielectric loss and preparation method thereof

A technology of lead niobate manganate and lead niobate nickelate, applied in the field of piezoelectric materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

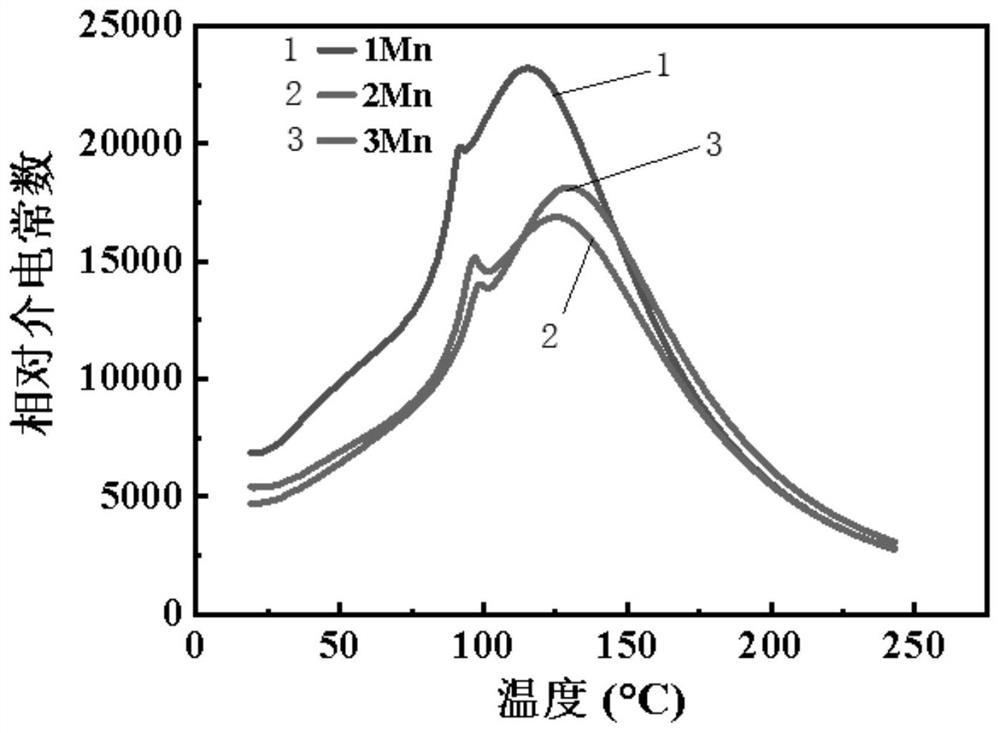

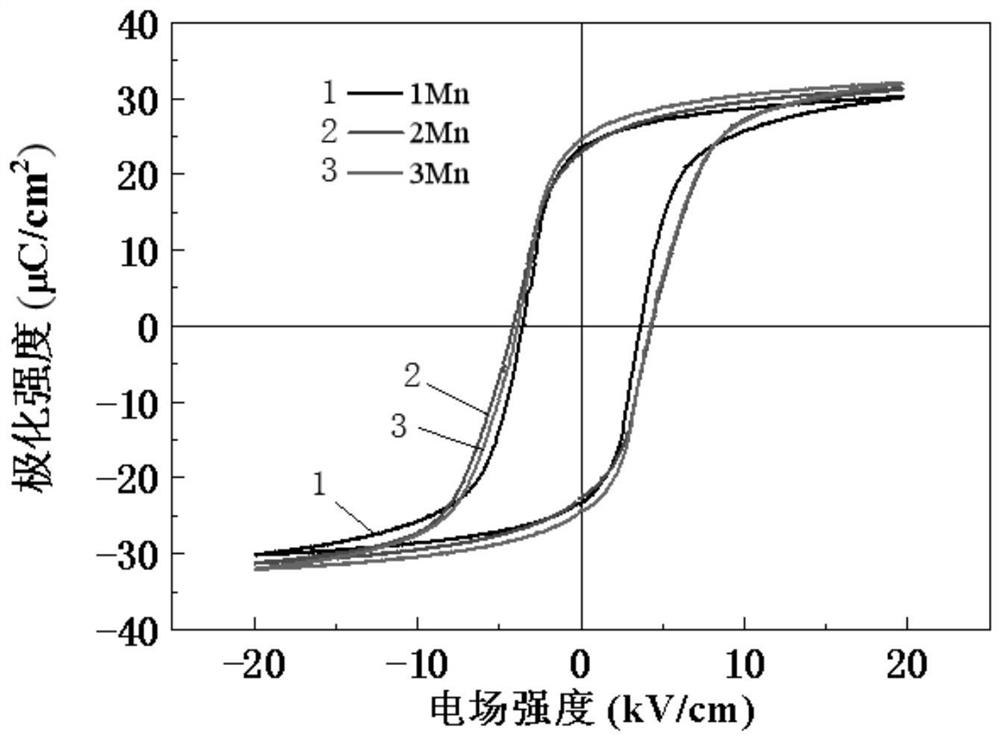

[0027] Embodiment 1: The chemical formula of a kind of ultra-low dielectric loss lead niobate manganate-lead niobate nickelate-lead zirconate titanate piezoelectric ferroelectric ceramics of this embodiment is xPb(Mn 1 / 3 Nb 2 / 3 )O 3 -(0.55-x)Pb(Ni 1 / 3 Nb 2 / 3 )O 3 -0.135PbZrO 3 -0.315PbTiO 3 , where x=0.1, 0.2, 0.3.

[0028] The method for preparing a kind of ultra-low dielectric loss lead niobate manganate-lead niobate nickelate-lead zirconate titanate piezoelectric ferroelectric ceramics of Example 1 is carried out according to the following steps:

[0029] Step 1. Ingredients: MnO 2 , PbO, TiO 2 , ZrO 2 , NiO, Nb 2 o 5 As a raw material, according to xPb(Mn 1 / 3 Nb 2 / 3 )O 3 -(0.55-x)Pb(Ni 1 / 3 Nb 2 / 3 )O 3 -0.135PbZrO 3 -0.315PbTiO 3 The stoichiometric ratio of raw materials is weighed, wherein the amount of PbO is 1.5% in excess, and dried by ball milling; where MnO 2 , PbO, TiO 2 , ZrO 2 , NiO, Nb 2 o 5 All are commercially available chemically pure ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com