An ultra-low dielectric loss lead niobate manganate-lead niobate nickelate-lead zirconate titanate high piezoelectric ferroelectric ceramic and its preparation method

A technology of lead niobate manganate and lead niobate nickelate, applied in the field of piezoelectric ferroelectric materials, to achieve the effect of expanding the application range, reducing the driving voltage, and avoiding the effect of performance collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

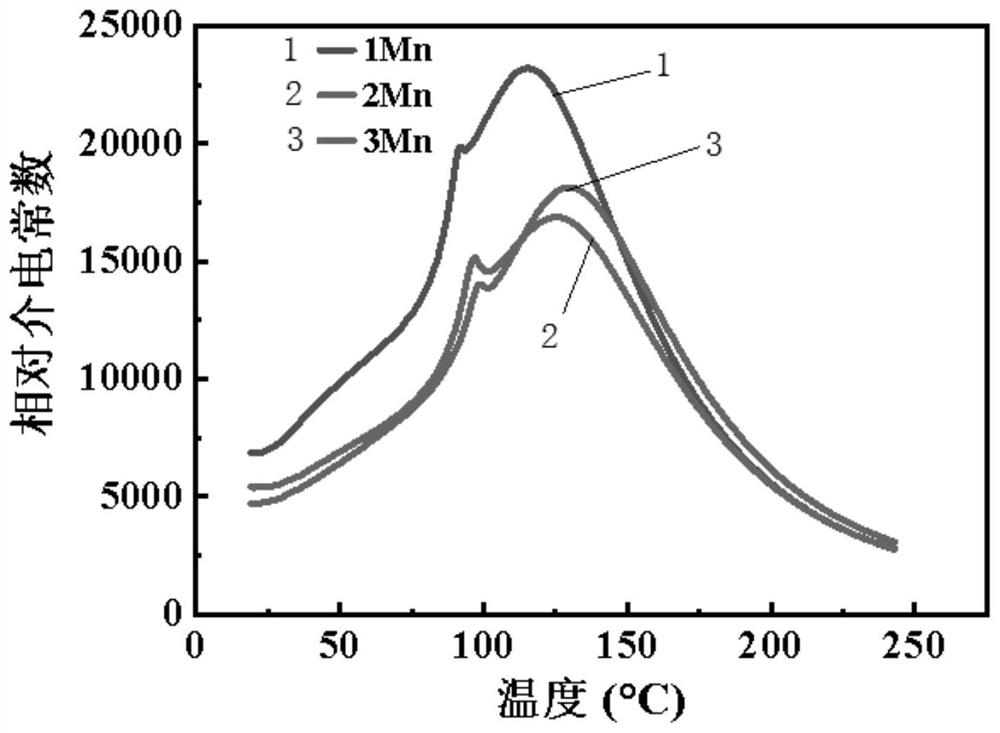

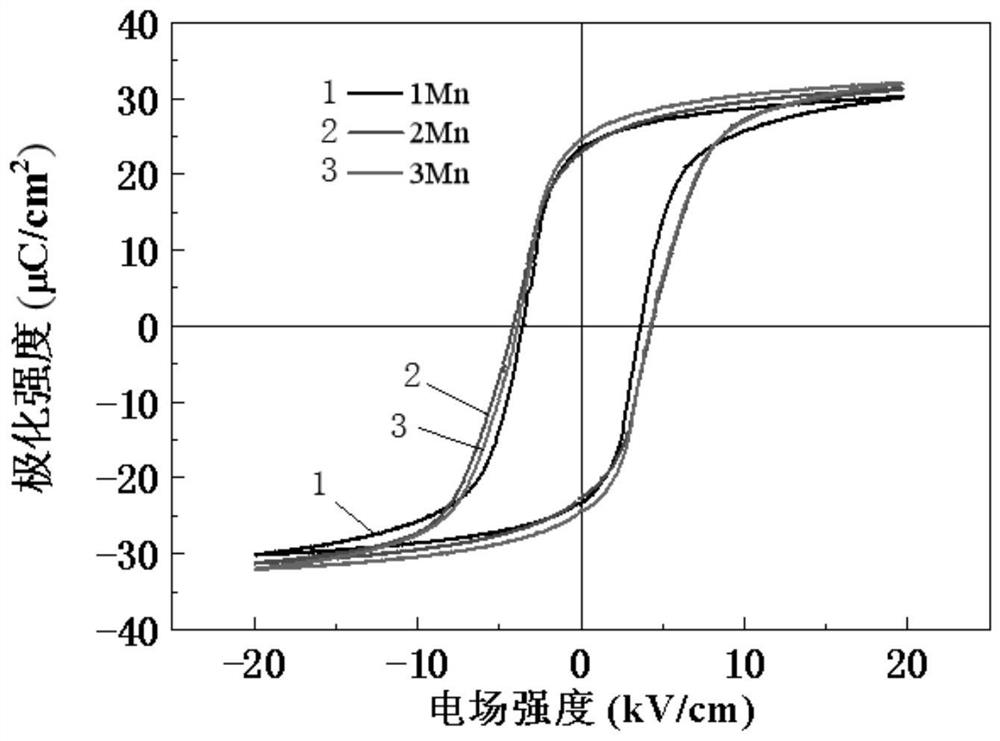

[0027] Embodiment 1: The chemical formula of an ultra-low dielectric loss lead manganate-lead niobate-lead zirconate titanate high-voltage electrical ferroelectric ceramic is xPb(Mn 1 / 3 Nb 2 / 3 )O 3 -(0.55-x)Pb(Ni 1 / 3 Nb 2 / 3 )O 3 -0.135PbZrO 3 -0.315PbTiO 3 , where x=0.1, 0.2, 0.3.

[0028] The method for preparing the ultra-low dielectric loss lead manganate-lead niobate-lead zirconate titanate high-voltage electrical ferroelectric ceramics of Example 1 is carried out according to the following steps:

[0029] Step 1. Ingredients: with MnO 2 , PbO, TiO 2 , ZrO 2 , NiO, Nb 2 O 5 As a raw material, according to xPb (Mn 1 / 3 Nb 2 / 3 )O 3 -(0.55-x)Pb(Ni 1 / 3 Nb 2 / 3 )O 3 -0.135PbZrO 3 -0.315PbTiO 3 The stoichiometric ratio of raw materials was weighed, wherein the amount of PbO material was excessive by 1.5%, ball milled and dried; wherein MnO 2 , PbO, TiO 2 , ZrO 2 , NiO, Nb 2 O 5 They are all commercially available chemically pure raw materials (purity ≥99%);...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com