Preparation method of all-water MDI foaming antibacterial polyurethane for shoe material

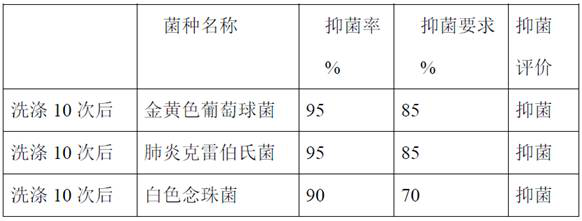

A polyurethane and shoe material technology, applied in the field of health care insoles, can solve the problems of low fluoride, no sweat absorption and moisture conduction function, foot discomfort, etc., and achieve the effects of simple and convenient operation process, excellent sweat absorption function, and long-term antibacterial performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of preparation method that is used for shoe material full water MDI foaming antibacterial polyurethane is divided into the following steps:

[0027] S.1 Weigh 100 parts of polyether polyol, 2 parts of emulsifier, 1 part of amine ether foaming catalyst, 3 parts of alcohol amine crosslinking agent (diethanolamine), 0.05 part of antibacterial agent KY01 and 0.5 part of foaming agent (Purified water) In the reaction vessel, after electric stirring and mixing, introduce into the material tank, turn on the material tank agitator, and heat the material tank to 50°C, continue to stir for 2 hours, and vacuum filter to obtain the mixture A;

[0028] S.2 Under the normal operation of the machine, according to the weight ratio, mix the mixture A and diphenylmethane diisocyanate at a weight ratio of 1:4, inject the mixed material into the mold through the automatic PU pouring machine, and The foamed antibacterial polyurethane used for shoe materials can be obtained after foam...

Embodiment 2

[0030] A kind of preparation method that is used for shoe material (cushion) all-water MDI foam antibacterial polyurethane is divided into the following steps:

[0031] S.1 Weigh 100 parts of polyether polyol, 0.05 parts of emulsifier, 0.7 parts of amine ether foaming catalyst, 1 part of alcohol amine crosslinking agent (diethanolamine), 1.5 parts of antibacterial agent KY01 and 3 parts of foaming agent (Purified water) In the reaction vessel, after electric stirring and mixing, introduce into the material tank, turn on the material tank agitator, heat the material tank to 60°C, continue stirring for 0.5 hours, and vacuum filter to obtain the mixture A;

[0032] S.2 When the machine is running normally, according to the weight ratio, mix the mixture A and diphenylmethane diisocyanate at a weight ratio of 1:1, inject the mixed material into the mold through the automatic PU pouring machine, and The foamed antibacterial polyurethane used for shoe materials can be obtained after ...

Embodiment 3

[0034] A kind of preparation method that is used for shoe material (cushion) all-water MDI foam antibacterial polyurethane is divided into the following steps:

[0035] S.1 Weigh 100 parts of polyether polyol, 1.3 parts of silicone oil emulsifier, 0.05 parts of amine ether foaming catalyst, 2 parts of alcohol amine crosslinking agent (diethanolamine), 2 parts of antibacterial agent KY01 and 2 parts of foaming agent The agent (purified water) is in the reaction vessel, after electric stirring and mixing, it is introduced into the material tank, the mixer of the material tank is turned on, and the material tank is heated to 55 °C, and the stirring is continued for 1.3 hours, and the mixture A is obtained by vacuum filtration;

[0036] S.2 Under the normal operation of the machine, according to the weight ratio, mix the mixture A and diphenylmethane diisocyanate at a weight ratio of 4:1, inject the mixed material into the mold through the automatic PU pouring machine, and The foa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com