Tear-resistant and degradable polylactic acid food packaging film and preparation method thereof

A technology of food packaging film and polylactic acid, applied in the field of packaging materials, can solve the problems of high brittleness of polylactic acid, low tear strength, limited application of polylactic acid film, etc., to improve tear strength, expand application range, and good degradation ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

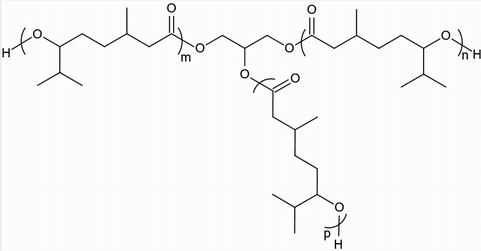

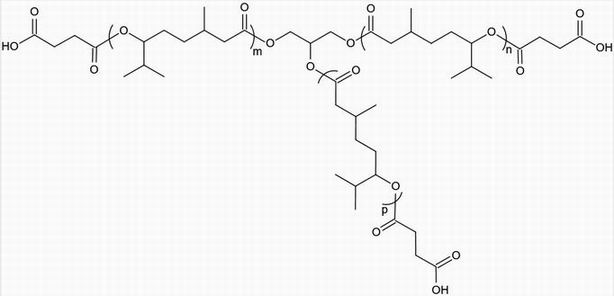

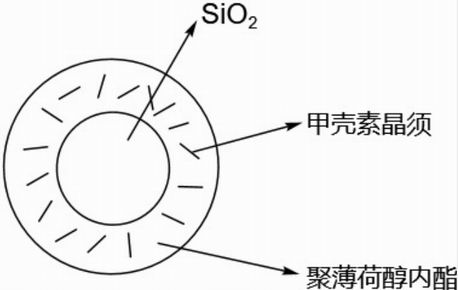

[0031] (1) Add menthol lactone monomer to toluene, then add glycerol, diethyl zinc, and urea, stir for 10 minutes, heat to 75°C for 13 hours under the protection of nitrogen, then drop glacial acetic acid to terminate the reaction, and Unreacted monomers and catalysts are removed by ice methanol precipitation at -20°C, and finally centrifuged to obtain hydroxyl-terminated star polymenthol lactone; among them, menthol lactone, toluene, glycerol, diethyl zinc, urea The mass ratio of glacial acetic acid and glacial methanol is 28:100:0.22:1.2:0.5:0.02:800;

[0032] (2) Add hydroxyl-terminated star polymenthol lactone into toluene, then add succinic acid and zirconia, stir for 20 minutes, heat to 100°C for 10 hours under the protection of nitrogen, and then rotary evaporate to remove toluene to obtain carboxyl-terminated star Type polymenthol lactone; wherein, the mass ratio of hydroxyl-terminated star polymenthol lactone, toluene, succinic acid, and zirconia is 28:100:6:0.4;

[...

Embodiment 2

[0037] (1) Add menthol lactone monomer to toluene, then add glycerol, diethyl zinc, and urea, stir for 20 minutes, heat to 65°C for 15 hours under nitrogen protection, then drop glacial acetic acid to terminate the reaction, and Unreacted monomers and catalysts are removed by ice methanol precipitation at -20°C, and finally centrifuged to obtain hydroxyl-terminated star polymenthol lactone; among them, menthol lactone, toluene, glycerol, diethyl zinc, urea The mass ratio of glacial acetic acid and glacial methanol is 32:100:0.15:1.5:0.5:0.02:600;

[0038] (2) Add hydroxyl-terminated star polymenthol lactone into toluene, then add succinic acid and zirconia, stir for 10 minutes, heat to 105°C for 8 hours under nitrogen protection, and then rotary evaporate to remove toluene to obtain carboxyl-terminated star Type polymenthol lactone; wherein, the mass ratio of hydroxyl-terminated star polymenthol lactone, toluene, succinic acid, and zirconia is 32:100:6:0.8;

[0039] (3) Add c...

Embodiment 3

[0043] (1) Add menthol lactone monomer to toluene, then add glycerol, diethyl zinc, and urea, stir for 12 minutes, heat to 70°C for 14 hours under the protection of nitrogen, then drop glacial acetic acid to terminate the reaction, and Unreacted monomers and catalysts are removed by ice methanol precipitation at -20°C, and finally centrifuged to obtain hydroxyl-terminated star polymenthol lactone; among them, menthol lactone, toluene, glycerol, diethyl zinc, urea The mass ratio of glacial acetic acid and glacial methanol is 30:100:0.2:1.4:0.4:0.025:700;

[0044] (2) Add hydroxyl-terminated star polymenthol lactone to toluene, then add succinic acid and zirconia, stir for 15 minutes, heat to 102°C for 9 hours under nitrogen protection, and then rotary evaporate to remove toluene to obtain carboxyl-terminated star Type polymenthol lactone; wherein, the mass ratio of hydroxyl-terminated star polymenthol lactone, toluene, succinic acid, and zirconia is 30:100:5:0.5;

[0045] (3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com