Solid lubricant and preparation method thereof

A technology for solid lubricants and preparation steps, applied in lubricating compositions, petroleum industry, etc., can solve the problems of reducing the strength, toughness and wear resistance of composite materials, continuous damage of matrix, and loss of lubricity, etc., to improve strength, toughness, Protects against oxidation damage and improves lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

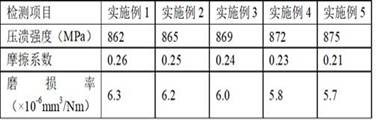

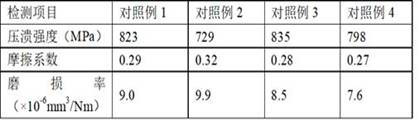

Examples

Embodiment 1

[0036] Weigh expandable graphite and put it into a vacuum freeze-drying box to freeze-dry, then put the dried expandable graphite into a microwave reactor, treat it with a power of 1.3kW for 30s, then cool it naturally to room temperature, and heat and expand it by circulating microwave treatment for 5 times, to obtain expanded graphite;

[0037] In parts by weight, 70 parts of nickel nitrate, 60 parts of molybdenum chloride, 40 parts of aluminum chloride, 8 parts of cobalt nitrate and 8 parts of yttrium chloride were weighed to obtain a mixed salt, and the mixed salt was heated to 200 ° C. Put the mixed salt into the electrolytic cell after melting, use the aluminum sheet as the positive electrode, and use the above-mentioned expanded graphite as the negative electrode, keep the distance between the two stages at 40mm, and the current density is 1.06A / dm 2 After electroplating for 4 hours under certain conditions, remove the electroplated negative electrode, which is composit...

Embodiment 2

[0043] Weigh the expandable graphite and put it into a vacuum freeze-drying box to freeze-dry, then put the dried expandable graphite into a microwave reactor, treat it with a power of 1.3 kW for 31 seconds, then cool it down to room temperature naturally, and heat and expand it by circulating microwave treatment for 5 times, to obtain expanded graphite;

[0044] In parts by weight, 72 parts of nickel nitrate, 62 parts of molybdenum chloride, 42 parts of aluminum chloride, 8 parts of cobalt nitrate and 8 parts of yttrium chloride were weighed to obtain a mixed salt, and the mixed salt was heated to 205 ° C. Put the mixed salt into the electrolytic cell after melting, use the aluminum sheet as the positive electrode, and use the above-mentioned expanded graphite as the negative electrode, keep the distance between the two stages at 40mm, and the current density is 1.06A / dm 2 After electroplating for 4 hours under certain conditions, remove the electroplated negative electrode, ...

Embodiment 3

[0050] Weigh the expandable graphite and put it into a vacuum freeze-drying box to freeze-dry, then put the dried expandable graphite into a microwave reactor, treat it with a power of 1.4kW for 33s, then cool it naturally to room temperature, and heat and expand it by cyclic microwave treatment for 6 times, to obtain expanded graphite;

[0051] In parts by weight, 75 parts of nickel nitrate, 65 parts of molybdenum chloride, 45 parts of aluminum chloride, 9 parts of cobalt nitrate and 9 parts of yttrium chloride were weighed to obtain a mixed salt, and the mixed salt was heated to 210° C. Put the mixed salt into the electrolytic cell after melting, use the aluminum sheet as the positive electrode, and use the above-mentioned expanded graphite as the negative electrode, keep the distance between the two stages at 40mm, and the current density is 1.06A / dm 2 After electroplating for 4 hours under certain conditions, remove the electroplated negative electrode, which is composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com