Nuclear reactor plate fuel melting fluid-solid coupling meshless analysis method

A nuclear reactor and fluid-solid coupling technology, applied in chemical process analysis/design, computational theoretical chemistry, design optimization/simulation, etc., can solve problems such as roughness, simple model, and inability to meet severe accident analysis of reactors, and achieve accurate capture and convenience Effects on Modeling, Reducing Likelihood, and Probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0118] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

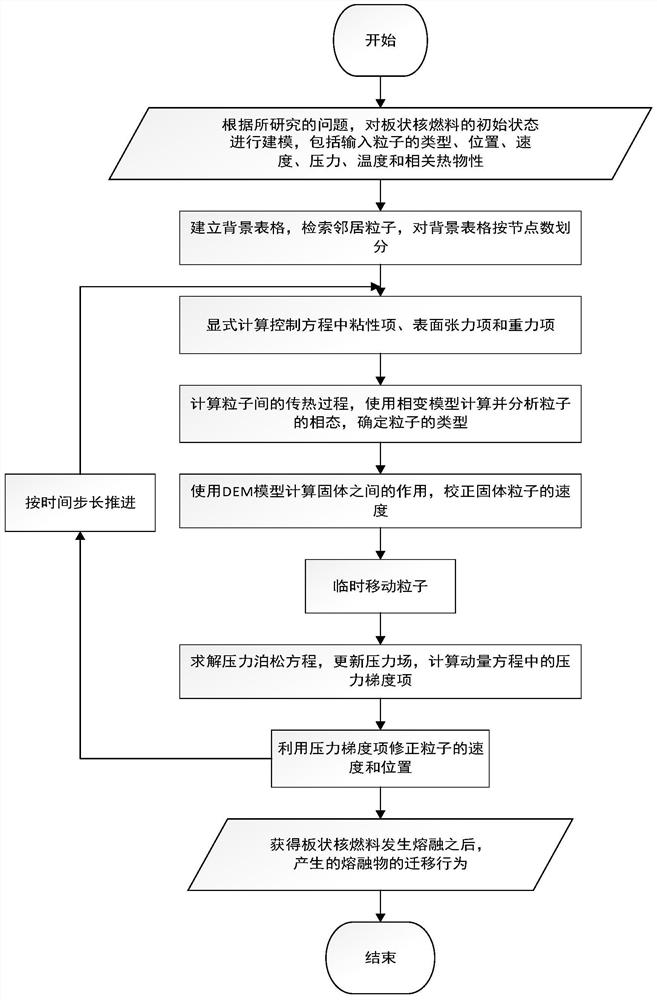

[0119] Such as figure 1 As shown, a kind of nuclear reactor plate-shaped fuel melting fluid-solid coupling gridless analysis method of the present invention, the steps are as follows:

[0120] Step 1: Particle modeling for the fluid-solid coupling problem of nuclear reactor plate fuel melting; different from the grid method, the particle method uses different types of particles to represent the various components of the nuclear reactor plate fuel, and particle 0 in this method represents zirconium alloy The material of fuel cladding and fuel matrix, No. 1 particle represents the uranium dioxide fuel particles dispersed in the fuel matrix; each particle is numbered, and all particles have corresponding physical parameters, including mass, density, specific Heat, melting and boiling point, temperature, enthalpy and initial velocity; pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com