Processing technology for sofa chair and device

A processing technology and processing device technology, applied in the field of sofa chairs, can solve the problems of reducing the stability of sofa chairs, high working strength, excessive bending, etc., to improve structural stability and force effect, reduce floor space and equipment Cost, effect of avoiding difference in deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

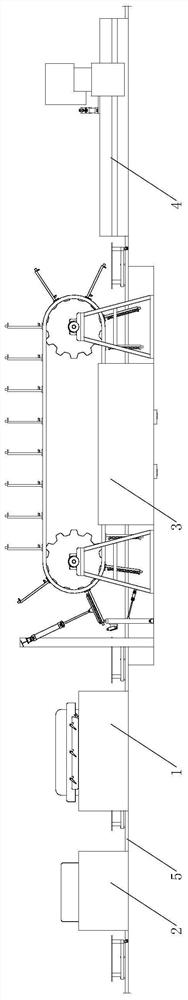

[0057] Example 1. Sofa chair processing technology, including the following steps:

[0058] 1 Cut, planer, puzzle, and engraving process for a variety of sheet materials, a set of accessories;

[0059] 2 assemble the A assembly accessories to the B couch;

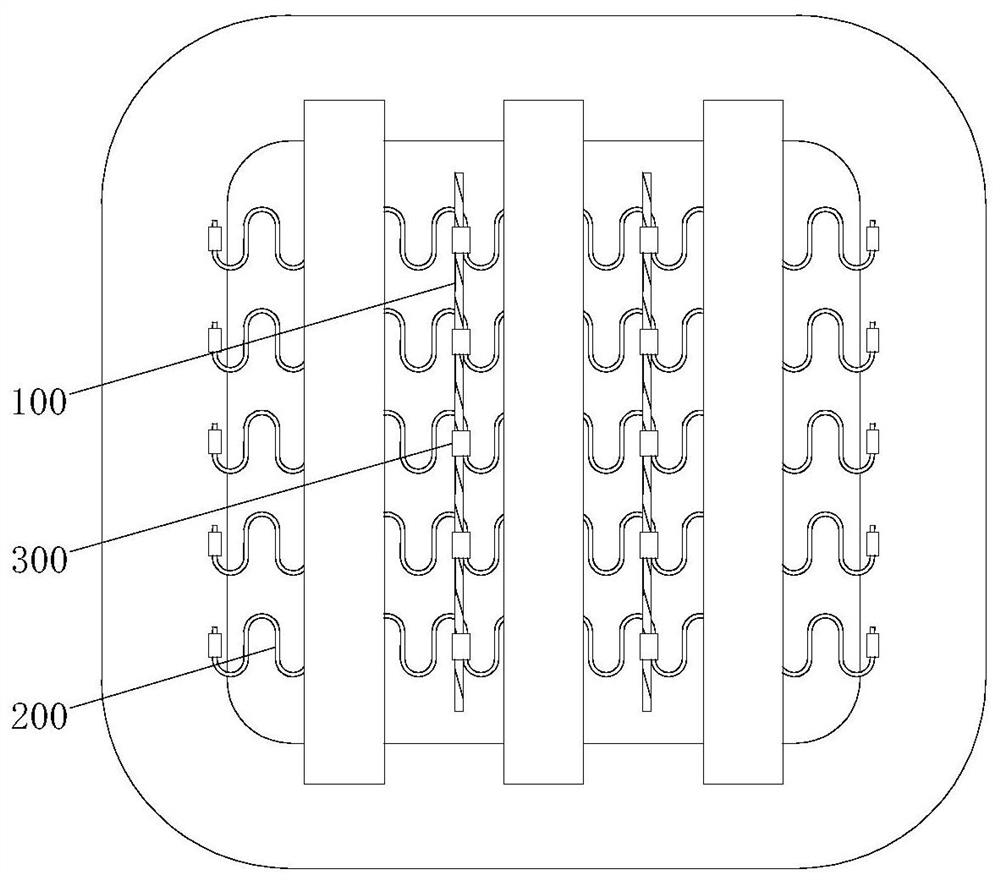

[0060] 3 Install multiple serpentinal springs in the middle of the B couch built-in chair, and connect each serpent spring between the serpenthes and the C Sofa inner frame;

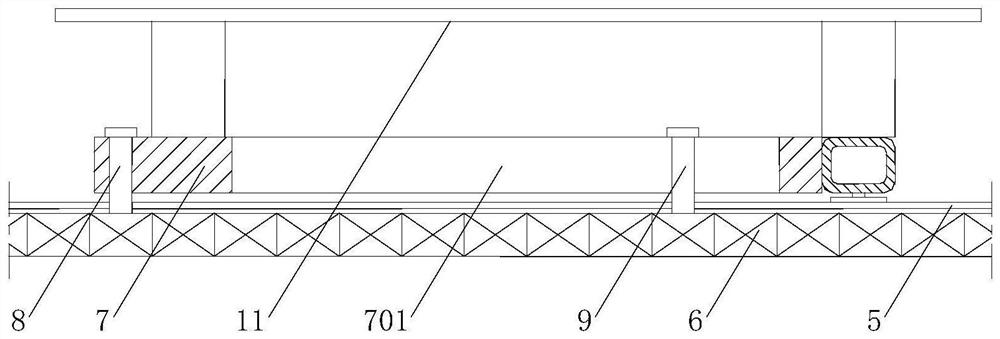

[0061] 4 The snake spring surface of the C sofa built-in surface is mounted, and the two ends of the cloth strip are connected to the C Sofa inner frame, the middle of the cloth strip is vertical and bonded to each other, and the D sofa endo;

[0062] 5 After coating the inner side of the elastic sponge and paste on the D sofa inner frame, and sewing the D sofa built by the elastic sponge in the form of the fabric to get an E sofa chair;

[0063] 6 Make an impact test, static pressure test, hanging foot test, and drop test, and get the finished sofa chair...

Embodiment 2

[0086] Example 2. Sofa chair processing technology, including the following steps:

[0087] 1 Cut, planer, puzzle, and engraving process for a variety of sheet materials, a set of accessories;

[0088] 2 assemble the A assembly accessories to the B couch;

[0089] 3 Install multiple serpentinal springs in the middle of the B couch built-in chair, and connect each serpent spring between the serpenthes and the C Sofa inner frame;

[0090] 4 The snake spring surface of the C sofa built-in surface is mounted, and the two ends of the cloth strip are connected to the C Sofa inner frame, the middle of the cloth strip is vertical and bonded to each other, and the D sofa endo;

[0091] 5 After coating the inner side of the elastic sponge and paste on the D sofa inner frame, and sewing the D sofa built by the elastic sponge in the form of the fabric to get an E sofa chair;

[0092] 6 Make an impact test, static pressure test, hanging foot test, and drop test, and get the finished sofa chair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com