Matrix filler with stable nitrogen and phosphorus removal effects, matrix and constructed wetland

A technology for nitrogen and phosphorus removal and constructed wetlands, which is applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc., can solve problems such as easy clogging and unstable nitrogen and phosphorus removal effects, and achieve non-pollution Globalization, good market application prospects, and outstanding effects on environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

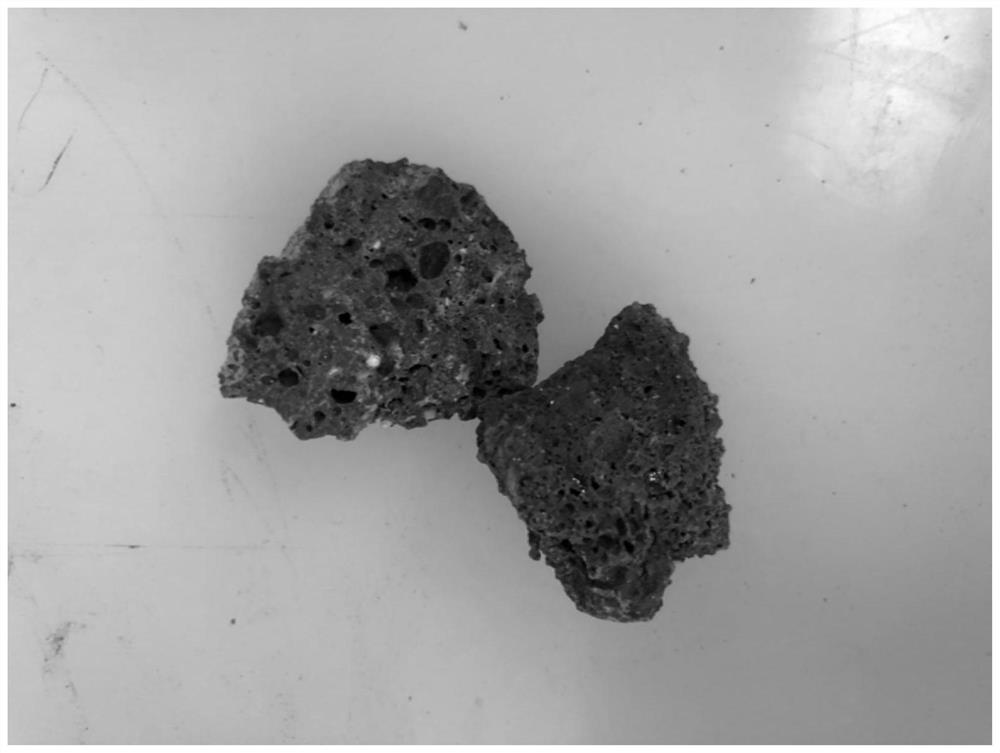

[0026] In this embodiment, the following method is used to pretreat the fuel ash of a biological power plant to obtain a matrix filler, and the obtained matrix filler is as follows: figure 1 Shown:

[0027] (1) Collect the ash produced in the combustion process of the biomass power plant, and sieve the ash to remove the powder with a particle size less than 1cm and the massive large particles with a particle size greater than 4cm;

[0028] (2) Use clear water to rinse the dust on the surface of the ash after the screening in the previous step, and soak in flowing clear water to remove impurities in the pores of the ash;

[0029] (3) After draining the ash, dry it at a temperature of 60°C;

[0030] (4) Sieve the dried ash and slag to obtain small particle fillers with a particle size of 1-2 cm and large particle fillers with a particle size of 3-4 cm.

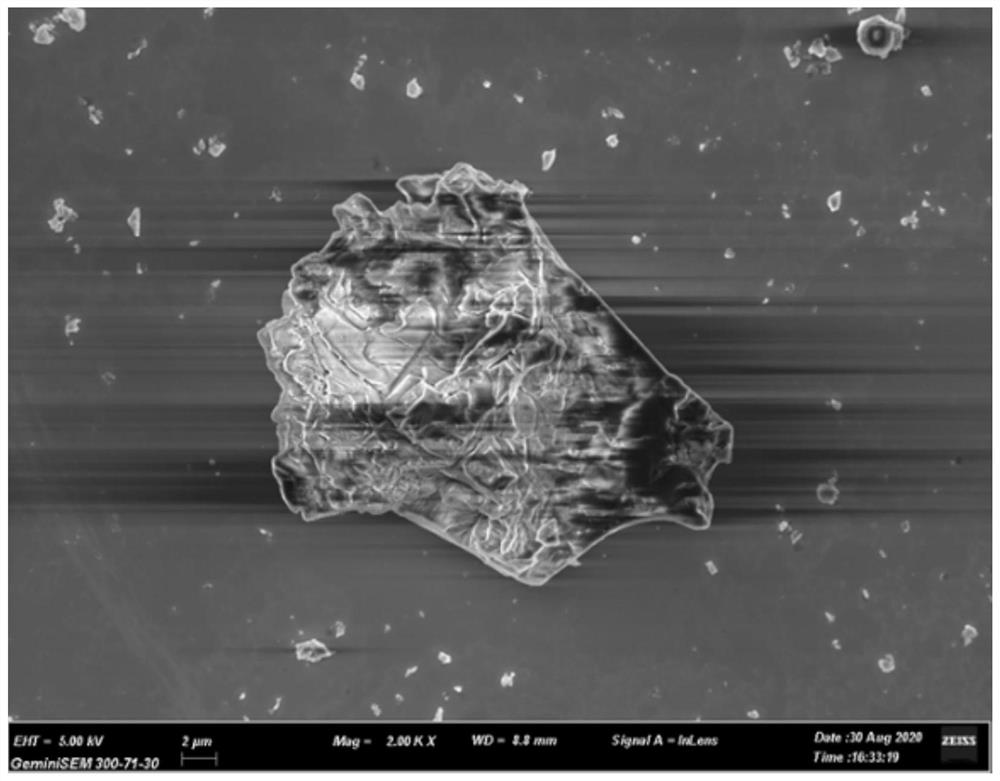

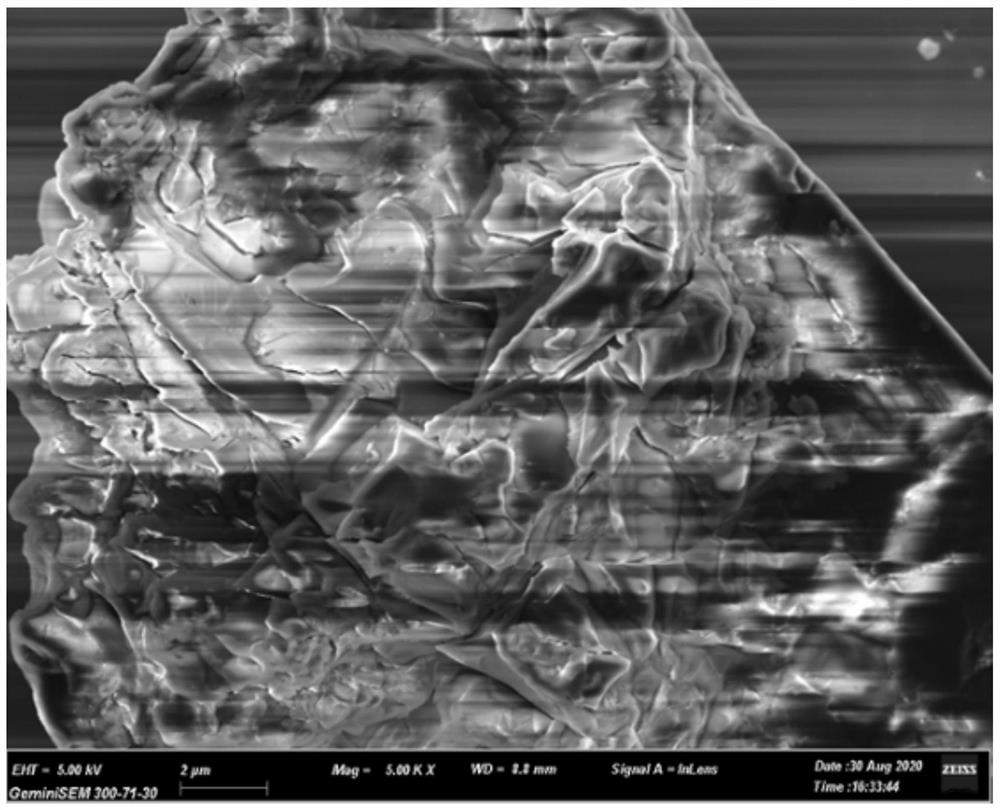

[0031] Wherein, the matrix filler in the present embodiment is observed by a scanning electron microscope (SEM), and the sca...

Embodiment 2

[0044] On the basis of Example 1, this example further verifies the denitrification and phosphorus removal effects of the matrix filler provided in Example 1 by building an experimental pool of a small-scale constructed wetland device.

[0045] In this embodiment, among the artificial wetland composite fillers used, the bottom layer is a gravel layer with a particle size of 8-10 cm and a thickness of 100-120 mm; the lower layer is ash with a large particle size of about 3-4 cm and a thickness of 120- 150mm; the upper layer is small particle size ash, about 1-2cm, and the thickness is 150-180mm. And plant plantain and reeds on the top layer with a density of 10-12 plants / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com