Method for rapidly forming zirconium film on surface of high-strength steel for automobile

A high-strength steel, fast technology, applied in the direction of metal material coating process, etc., can solve the problems of insignificant improvement of zirconium-based conversion coating defects, many cracks in zirconium-based conversion coating, low corrosion resistance, etc., to suppress the generation of hydrogen , Small influence on the environment and human body, the effect of improving the film forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

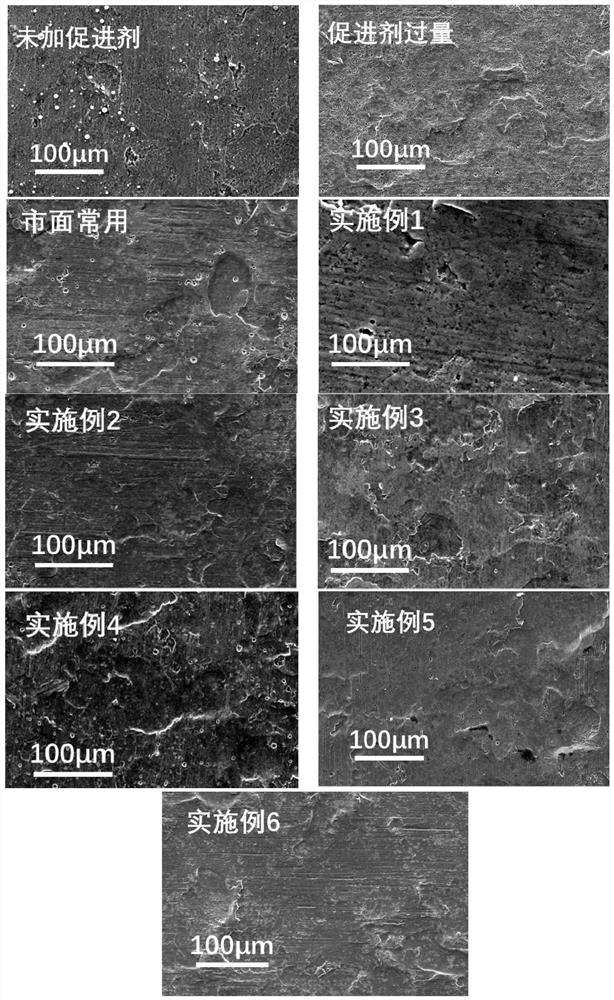

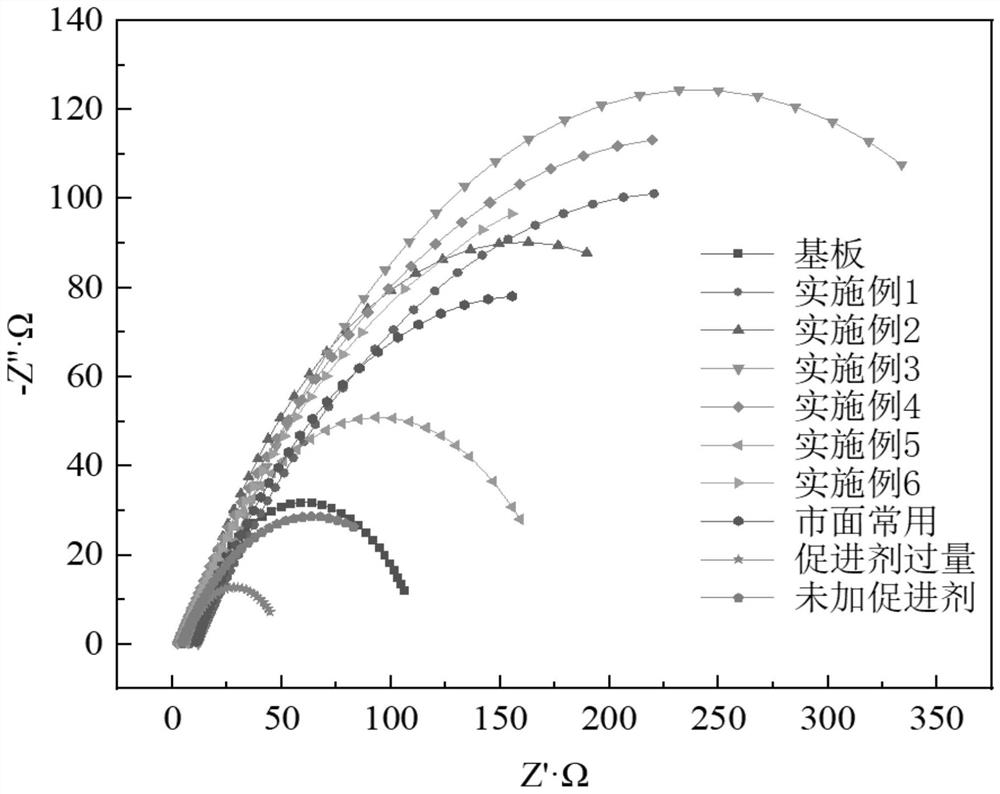

Examples

preparation example Construction

[0028] b. Preparation of zirconium-based conversion liquid: add 1-7g / L zirconating agent, 2-8g / L oxidizing agent, 0.2-10g / L complexing agent and 0.2-1.5g / L accelerating Agent, mix evenly and let stand;

[0029] c. Preparation of zirconium-based conversion film: Put the prepared zirconium-based conversion liquid in a container, add a pH regulator dropwise at room temperature to adjust the pH value of the zirconium-based conversion liquid to 3.8-4.2, then add water to a constant temperature water bath, and Place the container containing the zirconium-based conversion solution in a water bath and heat it. When the zirconium-based conversion solution reaches 23-27°C, keep the temperature constant, and hang the pretreated substrate in the zirconium-based conversion solution for zirconization treatment for 1-5 Minutes, the zirconium-based conversion solution is continuously stirred during the treatment process, the substrate is taken out after the treatment is completed, washed with...

Embodiment 1

[0032] A method for rapid film formation of zirconium film on the surface of high-strength steel for automobiles, the mass percentage of raw materials is as follows: 3g / L of zirconium agent, 5g / L of oxidizing agent, 4g / L of complexing agent, 0.2g / L of accelerator, and the balance is water.

[0033] Wherein, the zirconating agent is selected from fluozirconic acid.

[0034] Wherein, the oxidizing agent is selected from sodium tungstate.

[0035] Wherein, the complex is selected from ethylenediamineglycolic acid.

[0036] Wherein, the accelerator is calcium chloride.

[0037] According to the method described above, the raw materials are added in order to configure the conversion solution, and the pH of the conversion solution is adjusted to 4.0 by using a pH regulator. The pH regulator can be any pH regulator commonly used in the market; To treat the surface of high-strength steel, the steps are as follows:

[0038] (1) Use industrial alcohol to ultrasonically clean the high-...

Embodiment 2

[0042] A method for rapid film formation of zirconium film on the surface of high-strength steel for automobiles, the mass percentage of raw materials is as follows: 5g / L of zirconium agent, 6g / L of oxidizing agent, 6g / L of complexing agent, 0.6g / L of accelerator, and the balance is water.

[0043] Wherein, the zirconating agent is selected from fluozirconic acid.

[0044] Wherein, the oxidizing agent is selected from sodium tungstate.

[0045] Wherein, the complex is sodium pyrophosphate.

[0046] Wherein, the accelerator is calcium chloride.

[0047] According to the method described above, add raw materials in order to configure the conversion solution, and use the pH regulator to adjust the pH of the conversion solution to 3.9. The pH regulator can be any pH regulator commonly used in the market; To treat the surface of high-strength steel, the steps are as follows:

[0048] (1) Use industrial alcohol to ultrasonically clean the high-strength steel for 4 minutes, wash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com