House sound insulation floor and preparation method thereof

A technology for floors and houses is applied in the field of sound insulation floors of houses and the preparation thereof, which can solve the problems that sound insulation materials cannot meet the sound insulation requirements, and achieve the effects of various molding methods, no pollution to the environment, and simple preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

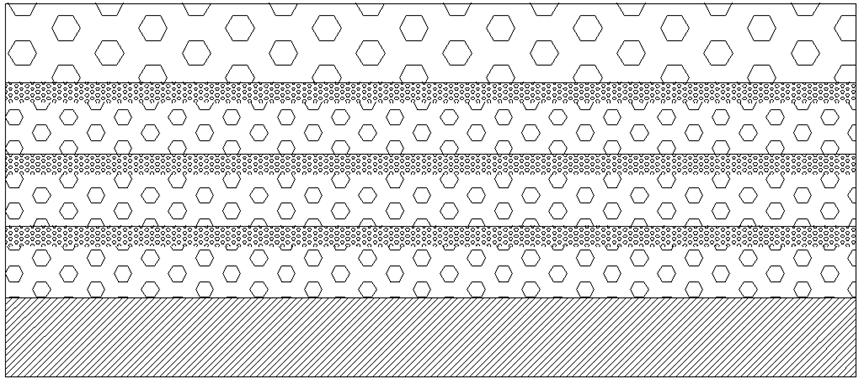

Image

Examples

Embodiment 1

[0025] A method for preparing a house soundproof floor, comprising the following steps:

[0026] (1) Mix 10kg of superfine cement, 30kg of sand, and 5kg of construction rubber powder evenly, add appropriate amount of water, spread it on the ground, beat it with a mortar board several times, eliminate air bubbles, and solidify to form a 3mm thick bottom sound insulation layer;

[0027] (2) Mix 40kg of cement, 5kg of construction rubber powder, 8kg of rubber powder, 15kg of expanded perlite, 10kg of mineral wool, and 1.5kg of 40% hydrogen peroxide; Put a layer of glass fiber cloth on it, and roll it with a roller several times to make the air bubbles on the surface volatilize to form a dense layer, and then solidify. The thickness of the dense layer is 1.5 mm; repeat the above steps once to form 2 layers of 5mm thick middle sound-absorbing layer;

[0028] (3) Mix 40kg of cement, 10kg of construction rubber powder, 80kg of rubber powder, and 2.5kg of 40% hydrogen peroxide; after ...

Embodiment 2

[0030] A method for preparing a house soundproof floor, comprising the following steps:

[0031] (1) Mix 10kg of ultra-fine cement, 40kg of sand, and 5kg of construction rubber powder evenly, add appropriate amount of water, spread it on the ground, beat it with a mortar board several times, eliminate air bubbles, and solidify to form a 5mm thick bottom sound insulation layer;

[0032] (2) Mix 40kg of cement, 5kg of construction rubber powder, 12kg of rubber powder, 10kg of expanded perlite, 5kg of mineral wool, and 0.5kg of foaming agent; A layer of glass fiber cloth, rolled with a roller several times to make the air bubbles on the surface volatilize to form a dense layer, and then solidify, the thickness of the dense layer is 0.8 mm; repeat the above steps twice to form 3 layers of 3mm thick middle sound-absorbing layer;

[0033] (3) Mix 40kg of cement, 10kg of construction rubber powder, 50kg of rubber powder, and 1.0kg of foaming agent; after mixing evenly, add an appropr...

Embodiment 3

[0035] A method for preparing a house soundproof floor, comprising the following steps:

[0036] (1) Mix 10kg of ultra-fine cement, 35kg of sand, and 5kg of construction rubber powder evenly, add appropriate amount of water, spread it on the ground, beat it with a mortar board several times, eliminate air bubbles, and solidify to form a 4mm thick bottom sound insulation layer;

[0037] (2) Mix 40kg of cement, 5kg of construction rubber powder, 10kg of rubber powder, 12kg of expanded perlite, 8kg of mineral wool, and 1.0kg of 40% hydrogen peroxide; Put a layer of glass fiber cloth on it, and roll it with a roller several times to make the air bubbles on the surface volatilize to form a dense layer, and then solidify, the thickness of the dense layer is 1.0 mm; repeat the above steps twice to form 3 layers of 4mm thick middle sound-absorbing layer;

[0038] (3) Mix 40kg of cement, 10kg of construction rubber powder, 65kg of rubber powder, and 2.0kg of 40% hydrogen peroxide; afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com