Rare earth cobalt permanent magnet, method and device for manufacturing same

A technology of rare earth cobalt permanent magnets and rare earth elements, which is applied in the direction of magnets, inductors/transformers/magnets, magnetic objects, etc., can solve problems such as motors, and achieve low coercive force, high squareness ratio, and high residual flux effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0128]

[0129] By using a high frequency furnace, at 1 x 10 -2 Torr or below 1×10 -2 A base alloy containing 20% by mass of Fe and 80% by mass of Zr and components containing various elements were melted in a Torr vacuum to obtain a composition of 25.0% by mass of Sm, 4.0% by mass of Cu, 21.0% by mass of Fe, 2.2 Alloy ingot of mass % Zr and balance Co.

[0130] Next, the obtained alloy ingot was heat-treated at 1170° C. for 15 hours, and then the heat-treated alloy ingot was coarsely pulverized and then finely pulverized into a powder having an average diameter of about 6 μm by using a jet mill in an inert gas. Next, by 1.0 ton / cm in a magnetic field of 15kOe 2 The powder was pressed with a pressure of , and a molded body having a length of 100 mm, a width of 50 mm, and a height of 50 mm was molded by using a mold.

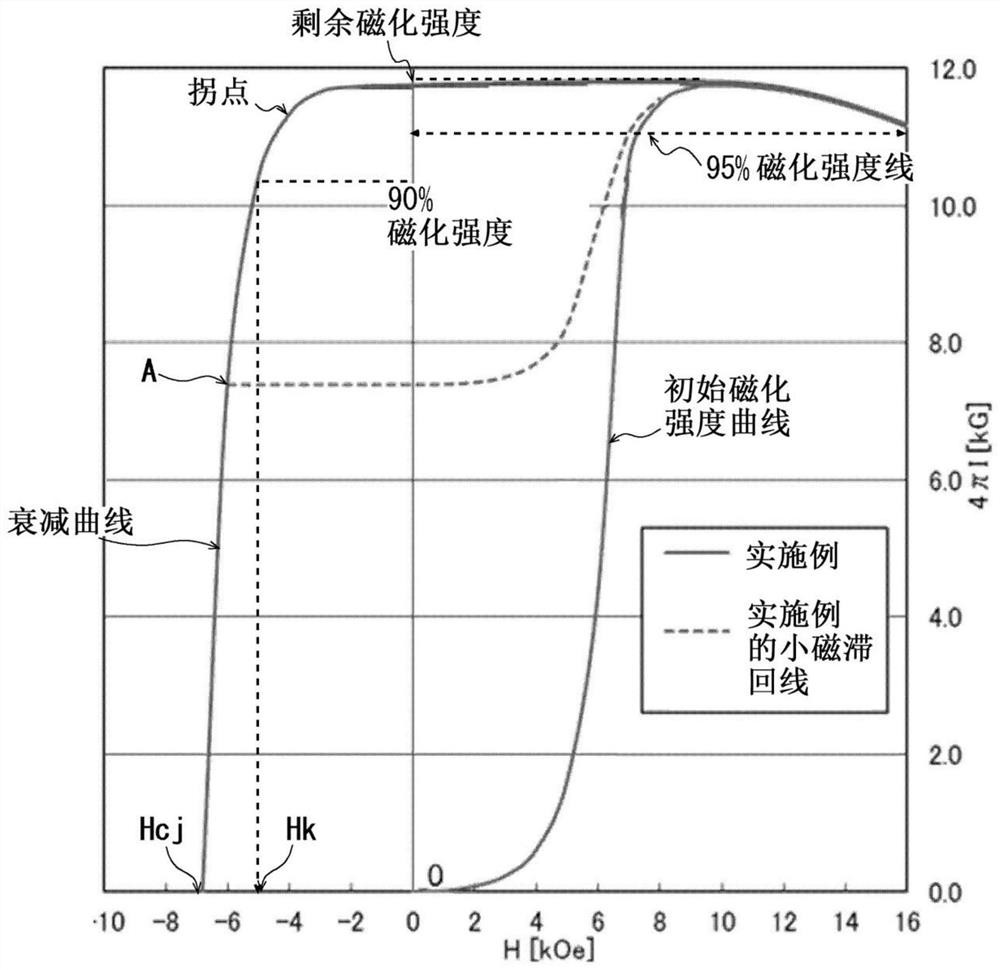

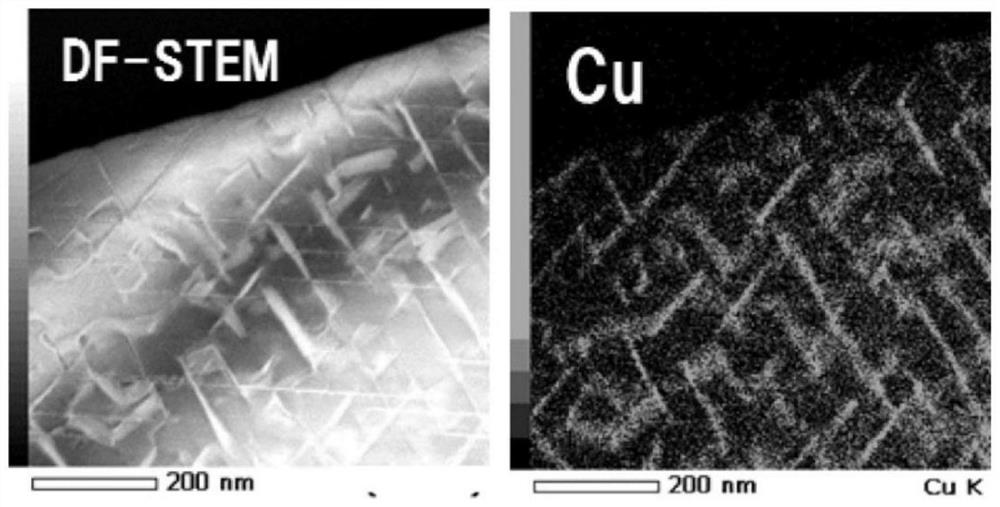

[0131] At a temperature of 1200 °C, the obtained molded body was prepared in 1 × 10 -2 Torr or below 1×10 -2 Sintering was carried out in Torr vacuum. ...

Embodiment 2

[0133]

[0134] A permanent magnet according to Example 2 was obtained in the same manner as in Example 1 except that the time of heating and holding at a temperature of 800° C. in the isothermal aging treatment was changed to 5 hours.

Embodiment 3

[0145]

[0146] Except for the amount of raw materials added, a molded body of an alloy ingot having a composition of 21.55% by mass of Fe, 25.65% by mass of Sm, 4.5% by mass of Cu, and 2.20% by mass of Zr was obtained in the same manner as in Example 1. and Co as the balance.

[0147] At a temperature of 1210 °C, the obtained molded body was prepared in 1 × 10 -2 Torr or below 1×10 -2 Sinter in Torr vacuum for one hour. Next, the sintered body was subjected to solution treatment at 1155° C. for 15 hours, and immediately thereafter the sintered body was cooled at a cooling rate of 100° C. / min. The rapidly cooled sintered body was subjected to isothermal aging by heating it in an inert gas atmosphere and maintaining it at a temperature of 750 °C for two hours. Then, the sintered body was gradually cooled to 400°C at a cooling rate of 2°C / min. In addition, the sintered body was subjected to isothermal aging treatment by heating and maintaining at a temperature of 765° C. f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Intrinsic coercive force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com