An oxide up-conversion luminescent material and its preparation method

A technology of luminescent materials and oxides, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of inability to obtain high-purity monoclinic MO, improper control of doping concentration, and difficulty in realizing it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a preparation method of the above-mentioned oxide up-conversion light-emitting material, comprising the following steps:

[0043] Weigh the solid compounds containing M element, Ln element, Li element and Ta element respectively according to the stoichiometric ratio, mix uniformly, and grind to obtain a mixture;

[0044] calcining the mixture at 1200-1600° C. for 3-5 hours to obtain a sintered body;

[0045] After grinding the sintered body, the oxide up-conversion light-emitting material is obtained.

[0046] Wherein, the solid compounds include oxides, carbonates, nitrates and halides, and the solid compounds containing M element, Ln element, Li element and Ta element are oxides containing M element, Ln element, Li element and Ta element at least one of carbonate, nitrate, or halide. The grinding is preferably wet mechanical ball milling for 10 hours, and the firing temperature is preferably 1300-1450°C.

[0047] The preparation me...

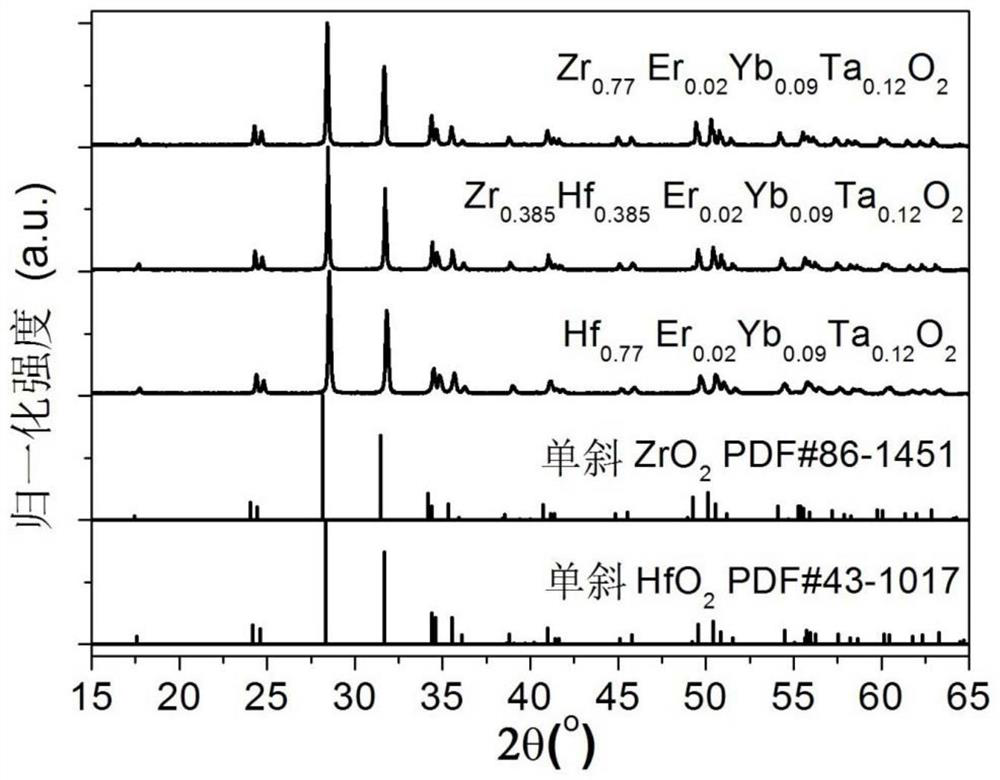

Embodiment 1

[0050] Zr 0.77 Er 0.02 Yb 0.09 Ta 0.12 O 2 The oxide up-conversion phosphor, the preparation process is as follows:

[0051] Weigh high-purity ZrO according to stoichiometric ratio 2 , Er 2 O 3 , Yb 2 O 3 and Ta 2 O 5 (In order to avoid the generation of impurity due to uneven grinding, Ta element is in excess of ~9% relative to rare earth ions when weighing), put it in a zirconia ball mill, add an appropriate amount of alcohol, use zirconia balls as the grinding medium, and use a planetary ball mill Grind for 10 hours, then dry in an electric heating drying oven for 10 hours, and collect fine powder samples uniformly mixed by vibrating sieving;

[0052] Put it into a high-purity corundum crucible and keep it at 1450℃ for 4h under air;

[0053] After cooling and discharging, a little grinding is performed to obtain a high-efficiency oxide up-conversion luminescent material.

Embodiment 2

[0055] Zr 0.385 hf 0.385 Er 0.02 Yb 0.09 Ta 0.12 O 2 The oxide up-conversion phosphor, the preparation process is as follows:

[0056] Weigh high-purity ZrO according to stoichiometric ratio 2 , HfO 2 , Er 2 O 3 , Yb 2 O 3 and Ta 2 O 5 (In order to avoid the generation of impurity due to uneven grinding, Ta element is in excess of ~9% relative to rare earth ions when weighing), put it in a zirconia ball mill, add an appropriate amount of alcohol, use zirconia balls as the grinding medium, and use a planetary ball mill Grind for 10 hours, then dry in an electric heating drying oven for 10 hours, and collect fine powder samples uniformly mixed by vibrating sieving;

[0057] Put it into a high-purity corundum crucible and keep it at 1450℃ for 4h under air;

[0058] After cooling and discharging, a little grinding is performed to obtain a high-efficiency oxide up-conversion luminescent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com