New post-treatment process for abradable al/bn seal coating of gas turbine parts

A sealing coating and gas turbine technology, which is applied in the coating process of metal materials, components and coatings of pumping devices for elastic fluids, etc., can solve the problem of insufficient application range and the service temperature of Al/BN sealing coating Problems such as low range, wear-resistant Al/BN sealing coating and new post-treatment process can achieve the effect of reducing friction damage, reducing failure or scrapping, and reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

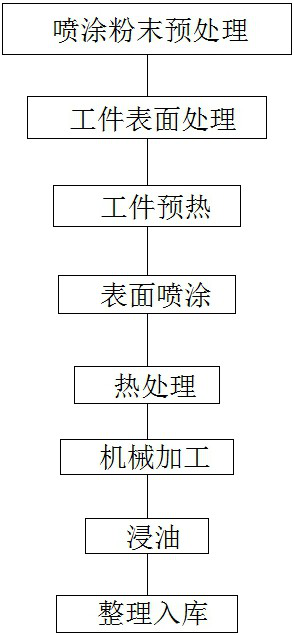

Image

Examples

Embodiment 1

Embodiment 2

[0042] The above spray powder pretreatment step can be divided into three sub-steps of taking, drying and sieving. Among them, take the step

[0043] The part surface treatment step is to clean and roughen the surface of the part to be sprayed. Part surface treatment steps

[0044] The preheating of the part is to place the part in an oven that can be heated to 60°C-90°C;

[0047] The heat treatment step is to heat treat the part to relieve coating stress. The heat treatment step is to place the part at 440°C‑

[0048] The machining step is to machine the part to bring the part to a set size. In the machining step, often

[0051] The step of sealing and packing the storage is to wipe off the friction reducing agent of the non-coating part on the part, and dry it for storage. In the package storage

Embodiment 3

[0056] The upper limit of the use temperature of the coating of the parts obtained by the above treatment process can be increased to 600°C. not only can

[0062] The cost of metal materials is 3,000 yuan × 10 pieces (scrapped at 30%) = 30,000 yuan; the cost of processing and coating materials is 10,000 yuan

[0066] Add items (2) to (3) and subtract item (1). It can be concluded that the cost saving for a single unit is: 353000+4800000‑

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com