Construction method of tunnel fireproof coating

A technology of fire-resistant coating and construction method, applied in fire-resistant coatings, coatings, tunnels, etc., can solve problems such as hidden dangers of safe driving, difficulties in safe driving, black holes, etc., to eliminate the phenomenon of black holes and white holes, and reduce light. Brightness difference, the effect of reducing the brightness difference between inside and outside

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Specifically, the preparation method of the energy storage light-emitting material includes the steps of:

[0048] The connecting pipelines of the ultrasonic reactor are in a sealed state, vacuum, and nitrogen gas;

[0049] Then, a solvent having an amount of 80% of the formulation amount is added to the ultrasonic reactor, and the ultrasonic stirring means is activated, and the nano-rare earth aluminate is slowly added to the solvent, and the mixture is stirred for 30 min;

[0050] The monomer material contains fluoroacrylic monomer, chloride, vinyl acetate, methacrylate, methyl methacrylate, butyl acrylate, methyl methacrylate, AH-171 vinyl trimethoxysilane , The sodium allyl sulfonate is mixed with a high speed disperser; the initiator AIBN azo diisobutyronitrile is dissolved by a solvent of 20% of the formulation amount;

[0051] The temperature of the reaction vessel was raised to 80 ° C, and the monomer and 80% initiator solution were added dropwise, and the 3-4 h was...

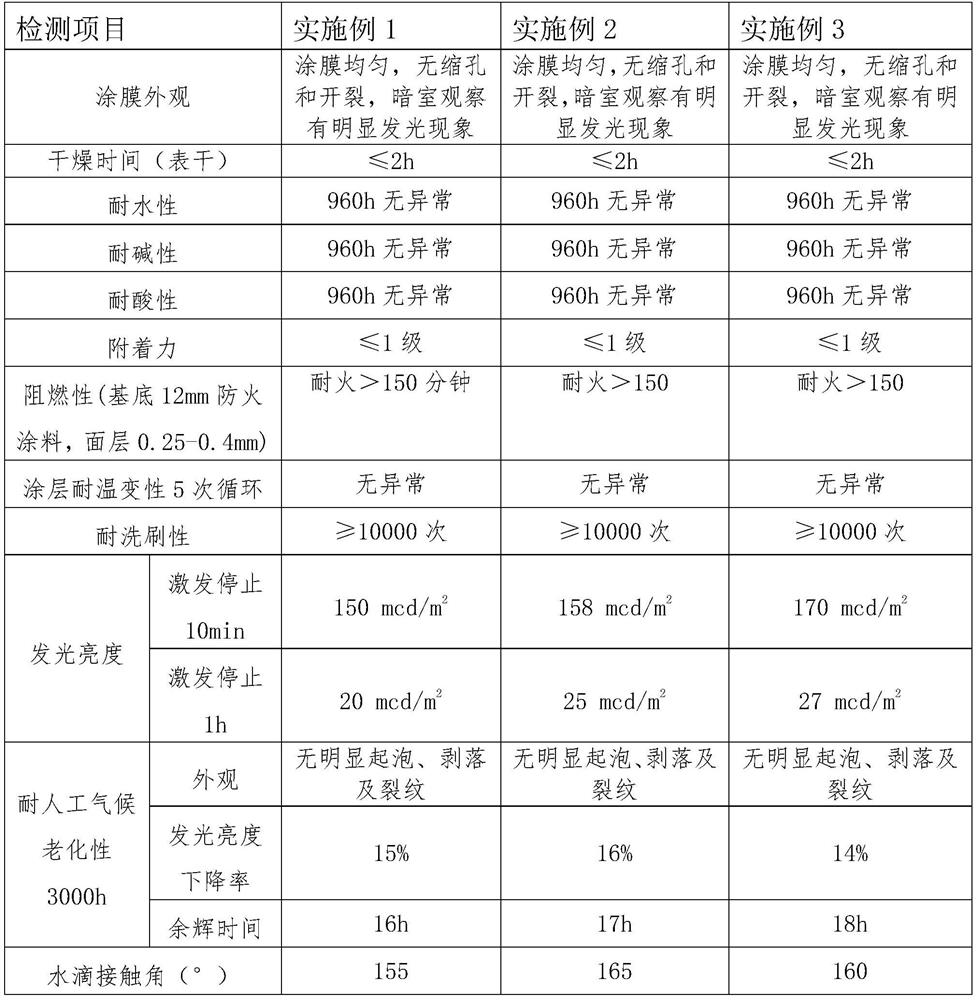

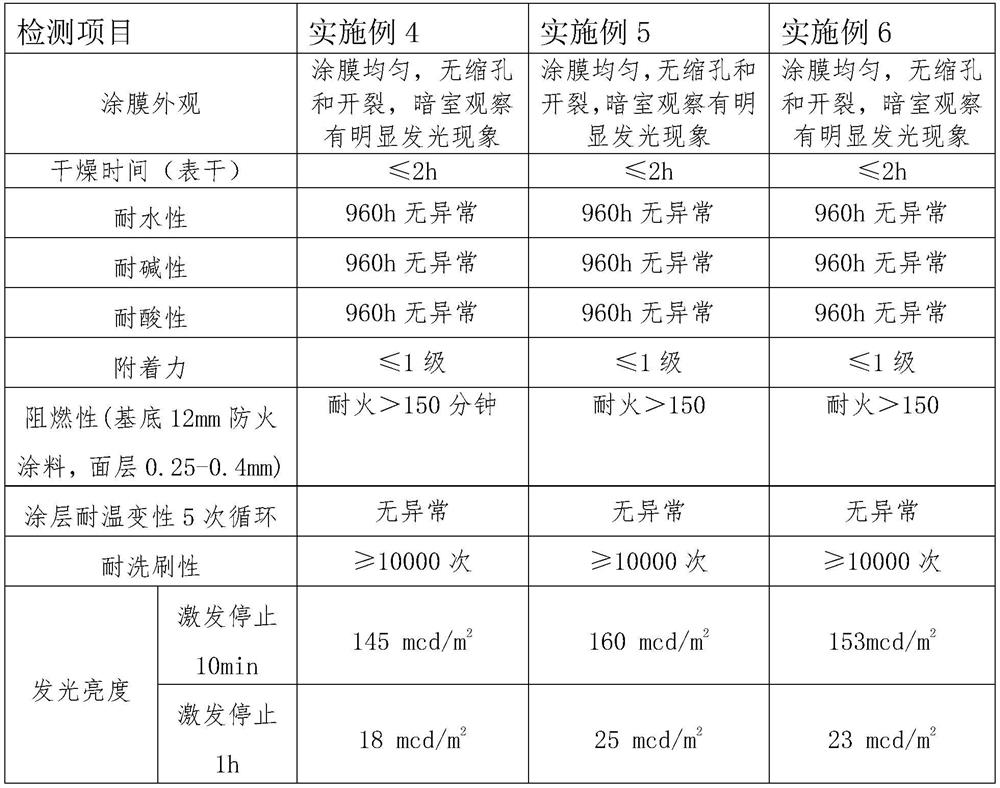

Embodiment 1

[0064] A aqueous energy storage, including the following components by weight parts:

[0065] 30 parts of the aqueous polyurea resin, 10 hydrolyte fluorocarbon resin, 15 parts of aqueous epoxy resin, 15 parts of the energy storage material, 5 flame retardants, 4 dispersants, 1 leveling agent, 1 part of the defoaming agent 8 parts of the curing agent, 50 parts by water;

[0066] Among them, the accumulator luminescent material is aqueous organic coated luminescent material, including the following components by weight percent:

[0067] 1 part of fluorine monomer, 1 part of chloride, 1 part of vinyl acetate, 1 part of methacrylate, 6 parts of methyl methacrylate, 6 parts of acrylate, 2 parts of methacrylate, 2 parts of methacrylate , 1 parts of AH-171 vinyl trimethoxysilane, 1 allyl sulfonate, 30 parts of propylene glycol, 20 n-butanol, 30 parts of nano-rare earth aluminate, AIBN azo diisobutyronitrile 2 share.

Embodiment 2

[0069] A aqueous energy storage, including the following components by weight parts:

[0070] 40 parts of water-based polyurea resin, 15 parts of aqueous fluorocarbon resin, 10 parts of aqueous epoxy resin, 25 parts of the accumulator, 8 flame retardants, 3 dispersants, 2 levels, 2 parts of antifoaming agent 5 parts of the curing agent and 60 water;

[0071] Among them, the accumulator luminescent material is aqueous organic coated luminescent material, including the following components by weight percent:

[0072] 1 part of fluorine monomer, 1 part of chloride, 1 part of vinyl acetate, 1 part of methacrylate, 6 parts of methyl methacrylate, 6 parts of acrylate, 2 parts of methacrylate, 2 parts of methacrylate , 1 parts of AH-171 vinyl trimethoxysilane, 1 allyl sulfonate, 30 parts of propylene glycol, 20 n-butanol, 30 parts of nano-rare earth aluminate, AIBN azo diisobutyronitrile 2 share.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com