Water washing type dye flaw detection penetrant taking water as developer as well as preparation method and use method of water washing type dye flaw detection penetrant

A technology of colored flaw detection and penetrant, which is applied in the preparation of test samples, optical testing of flaws/defects, etc. It can solve the problems of complex penetration testing and detection process, and achieve the effect of wide application range, good permeability and good diffusivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

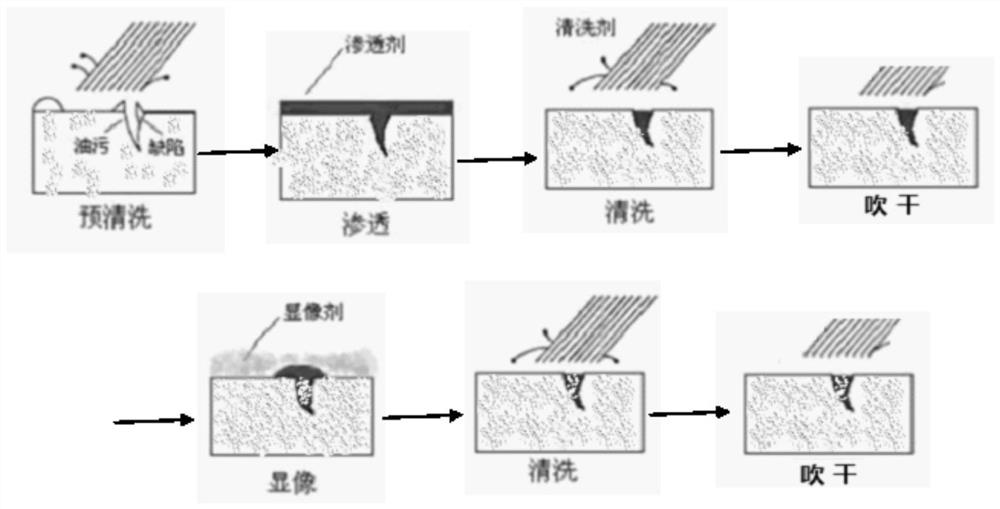

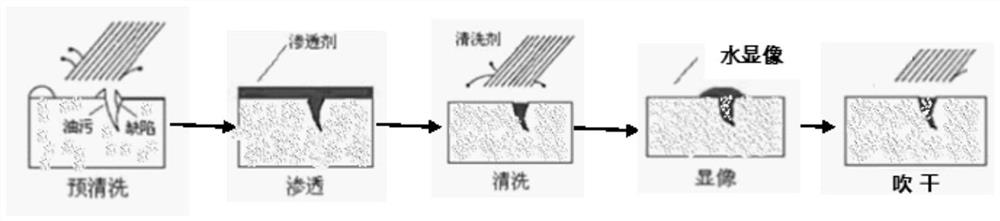

Method used

Image

Examples

Embodiment 1

[0055] A water-washing penetrating agent for colored flaw detection, wherein water can be used as both a cleaning agent and a developing agent, and is prepared as follows: 5 grams of hydrophilic red dye (Shanghai Mandia Dyestuff Co., Ltd., MB-21), lipophilic red dye Dyestuff (Shanghai Mandia Dyestuff Co., Ltd., MVQ-34) 1 gram, water-based emulsifier 35 grams (USA magnetic flux ZR-10B water-based emulsifier), ethylene glycol ether 20 grams, epoxy resin emulsion (Guangshu Chemical Industry, Put 10 grams of GS-5000B), 20 grams of isopropanol, 4 grams of amyl alcohol, and 5 grams of silicone defoamer into a container, stir at room temperature for 12 hours, and form a red and transparent water-washable coloring flaw detection penetrant after completely dissolving .

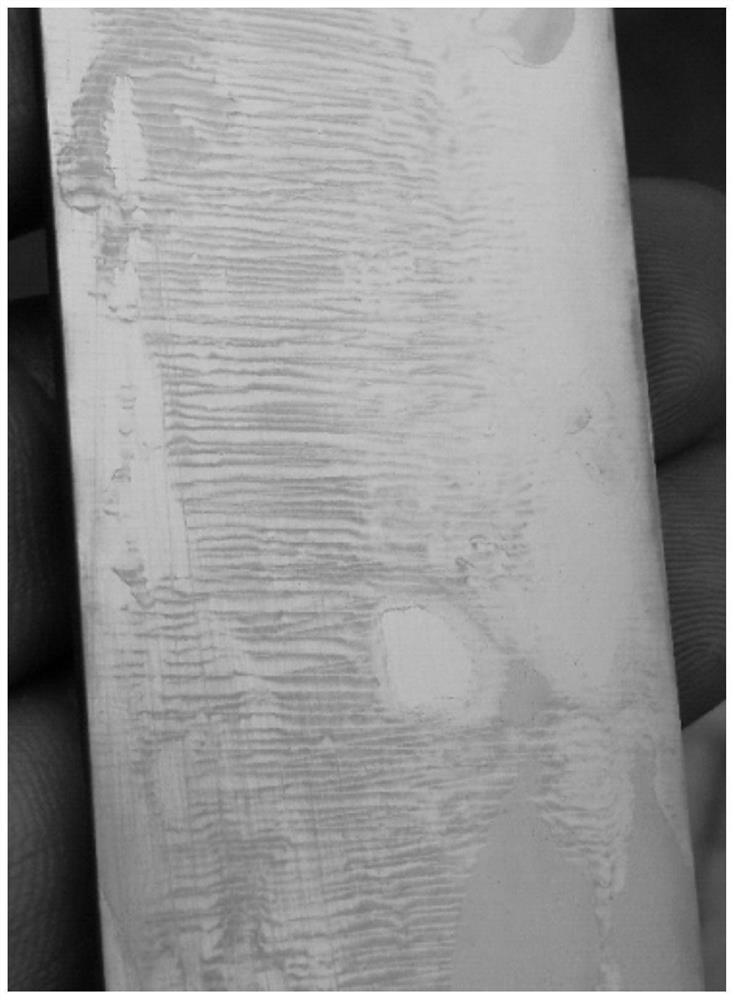

[0056] The use process of the water-washing colored flaw detection penetrant in Example 1: Spray the prepared colored penetrant on the E-type test block, the three-point type B-type test block and the aluminum alloy A-...

Embodiment 2

[0059] A water-washing penetrating agent for colored flaw detection, wherein water is used as both a cleaning agent and a developing agent, and is prepared as follows: 10 grams of water-soluble red dye (Shanghai Mandia Dyestuff Co., Ltd., SR-58), water-based emulsifier (chain Set chemical industry, PPG-400) 40 grams, ethylene glycol ethyl ether 20 grams, short oil alkyd resin 10 grams, oleic acid 3 grams, triethanolamine 7 grams, dibasic acid ester mixture 5 grams (DBE high boiling point solvent mixed two Monobasic acid ester is a mixture of dibasic acid esters, also known as dibasic acid esters, dicarboxylic acid esters), 5 grams of silicone defoamer, put it in a container, and stir at room temperature for 1 hour to completely dissolve, forming a red transparent water wash Type colored flaw detection penetrant.

[0060] The use process of the water-washing colored flaw detection penetrant in Example 2: Spray the prepared colored penetrant on the E-type test block, the aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com