Al(PO3)3 coated NCM811 positive electrode material and preparation method thereof

A technology of NCM811 and cathode materials, applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., can solve the problems of active materials being easily corroded, electrolyte side reactions, etc., and achieve the goal of improving electron transmission capacity, alleviating impedance, and reducing capacity Falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

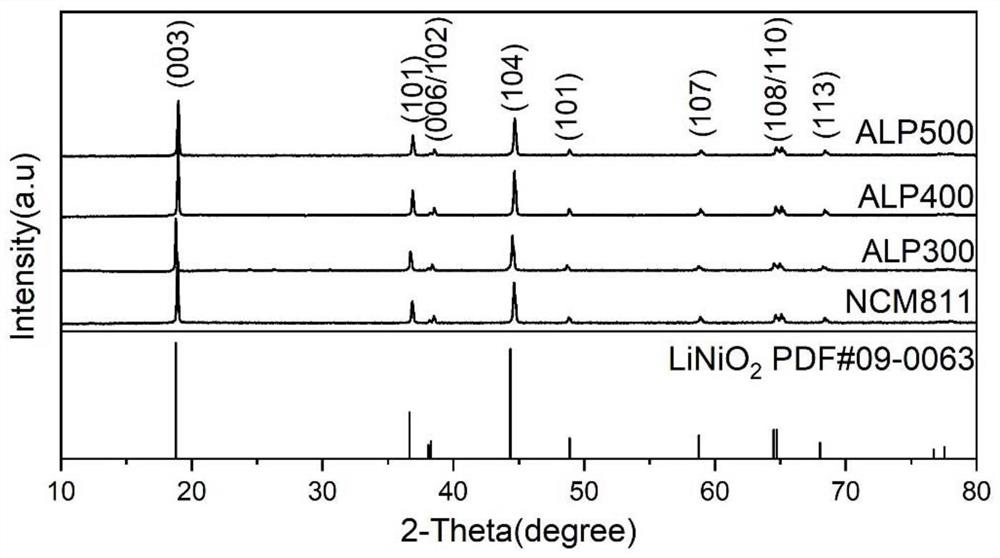

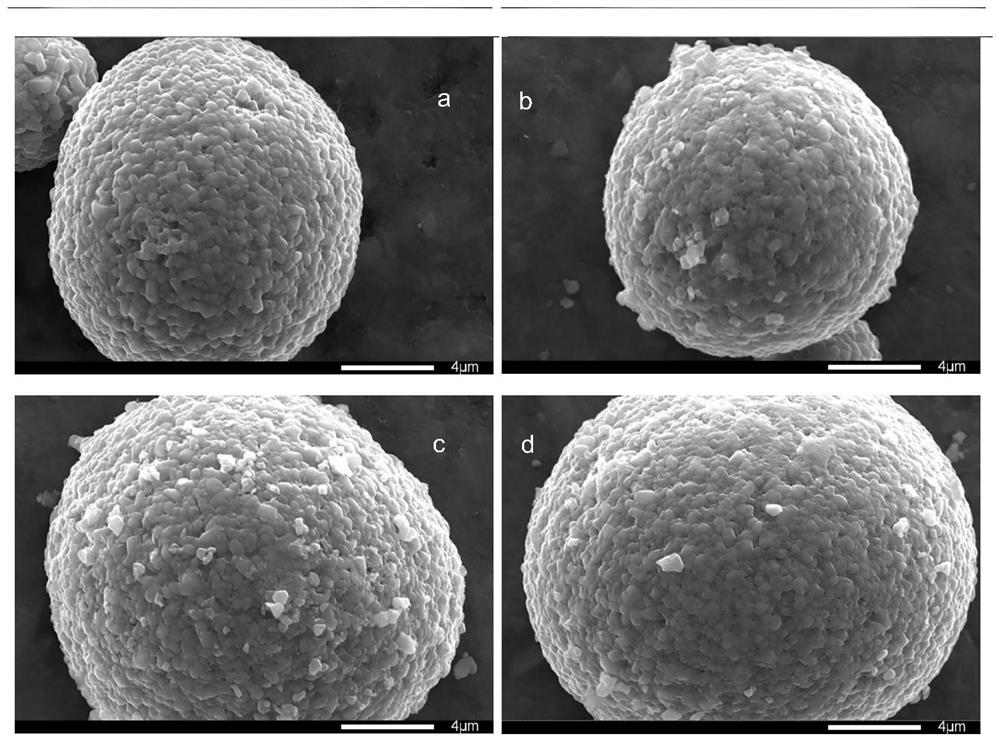

[0029] The coated NCM811 positive electrode material includes the following specific process steps:

[0030] The number of the high-nickel cathode material used is recorded as NCM811.

[0031] Step (1): According to commercial NCM811 and Al(PO 3 ) 3 The mass ratio is 50:1 to accurately weigh the positive electrode material;

[0032] Step (2): Grind the raw materials weighed in step (1) by dry grinding method, and control the grinding fineness by controlling the grinding time. The grinding time can be appropriately adjusted according to actual needs. When the mixed raw materials are fully mixed evenly and Stop grinding when the fineness is appropriate;

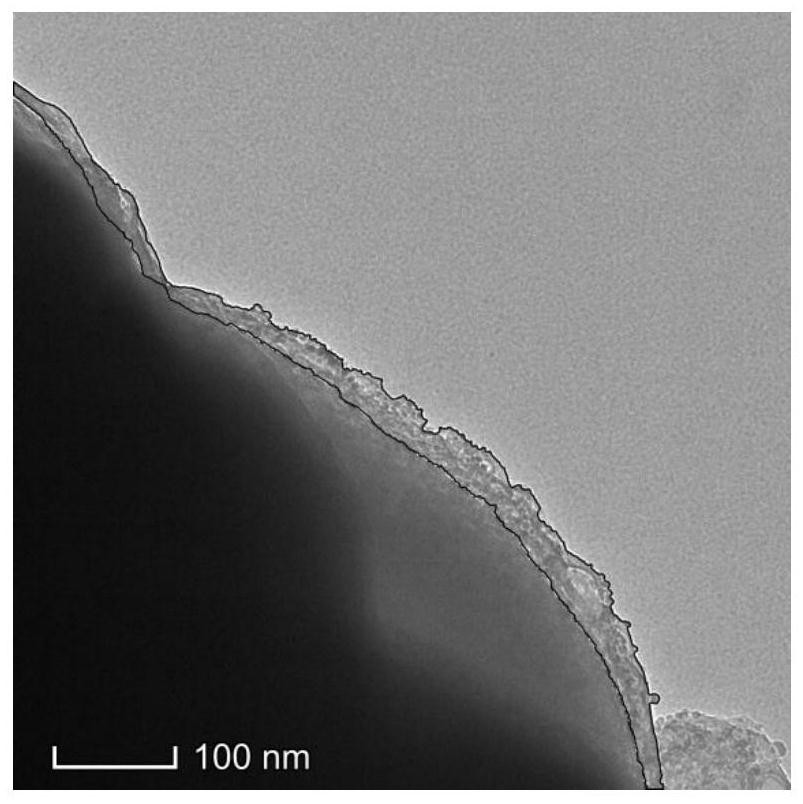

[0033] Step (3): Put the homogeneously mixed sample in step (2) into the sintering furnace, adjust the heating rate program of the sintering furnace to 5°C / min, when the sintering temperature reaches 300°C, keep warm for 5 hour, then take it out after natural cooling to obtain Al(PO 3 ) 3 Doped and coated high-nickel tern...

Embodiment 2

[0035] Except that the sintering temperature was changed to 400°C, the rest of the preparation method was the same as in Example 1, and the prepared sample was designated as ALP400.

Embodiment 3

[0037] Except that the sintering temperature was changed to 500°C, the rest of the preparation method was the same as in Example 1, and the prepared sample was designated as ALP500.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com